Official Tapflo Diaphragm Pumps

HDPE & PTFE Air Operated Diaphragm Pump

ATEX Metal Diaphragm Pump

Metal Diaphragm Pump

Sanitary Diaphragm Pump

ATEX HDPE/PTFE Diaphragm Pump

Powder Pump

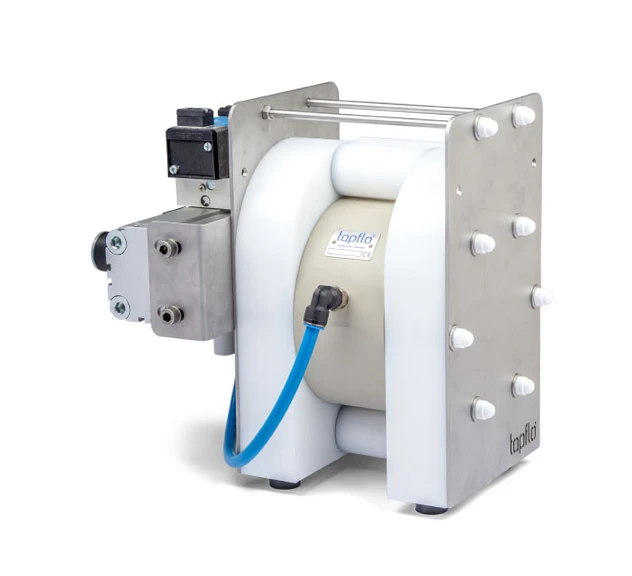

Barrier Diaphragm Pump

Aseptic EHEDG Diaphragm Pump

Pharmaceutical Pump

Diaphragm Drum Pump

Low Energy Air Pump

Low Energy Air Pump - Sanitary

Filter Press Diaphragm Pump

Electric Diaphragm Pump

Pulsation Dampeners for Diaphragm Pumps

Wall Mount Decanting Units

Insulating Covers for Diaphragm Pumps