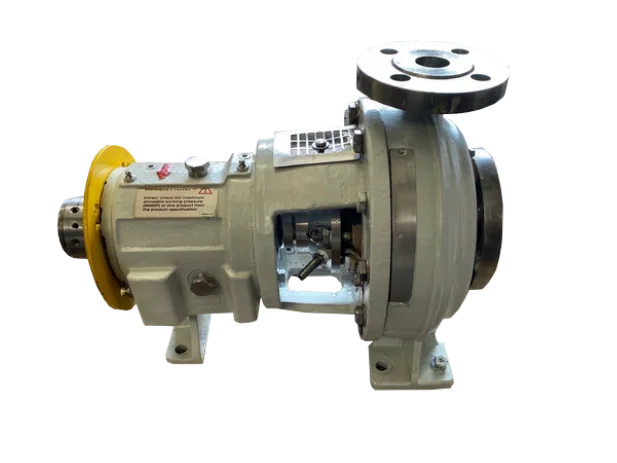

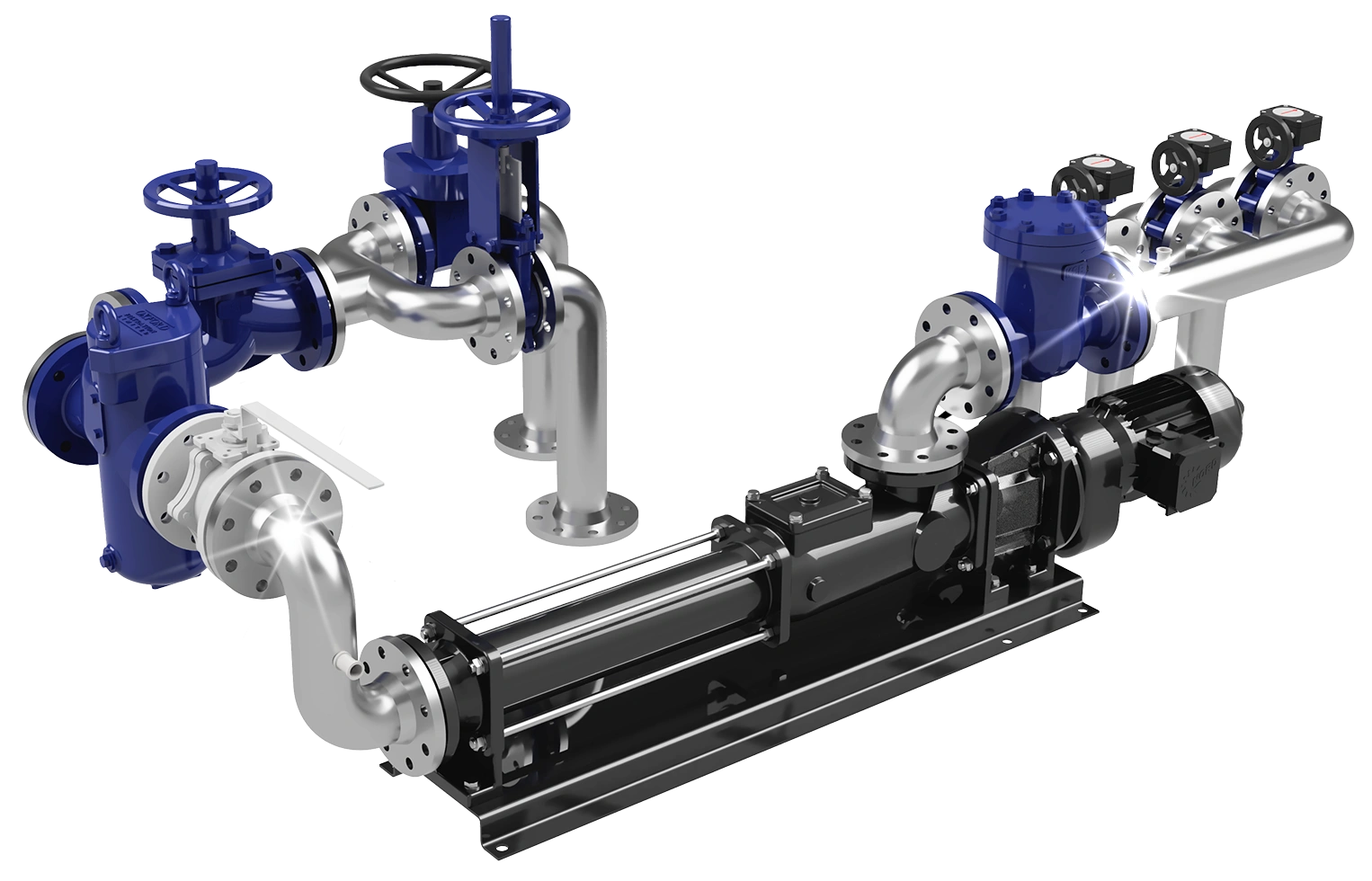

Our comprehensive servicing, maintenance, and repair department offer solutions for any pump age and type, ensuring peak pump performance. Expertly repaired and tested, 90% of pumps are salvaged rather than replaced, saving you money with an average savings of 40% on bespoke manufactured parts.

Tapflo UK offer full repair, servicing, and maintenance for all types of industrial and hygienic pumps for commercial use. Whether you need a one-off service, or a partner to keep your pumps running efficiently at all times, Tapflo UK can assist. Our team of engineers have many years of experience and can work with any type of pump, no matter how old or what brand.

Tapflo UK offer full repair, servicing, and maintenance for all types of industrial and hygienic pumps for commercial use. Whether you need a one-off service, or a partner to keep your pumps running efficiently at all times, Tapflo UK can assist.

Servicing

Repair

Maintenance

Audit

Two Leading Test Centres in the UK

Our Runcorn facility offers the option of performance testing using our 12,000L test tank for pumps up to 6”, with live data via a video link and totalised flow readings.

Tapflo UK have two of the fastest growing pump repair and service facilities in the UK and can service, maintain, and repair any brand of pump no matter how old.

Call us on:

02380 252 325Or Email us:

[email protected]