Established in 1990, Italian partner Nova Rotors specialise in manufacturing Progressive Cavity and Wobble Pumps. Certified ISO 9001:2015 and ISO 45001:2018, with capacities up to 420 m³/h and pressures up to 48 Bar, these pumps are built to a high standard being used within process systems across multiple industries.

Wobble Pump

Max. Temp

80C

Max. Head

40m

Max. flow

14.4m/hr

Materials

Metal

Hopper Pump

Max. Temp

150C

Max. Head

480m

Max. flow

110m/hr

Materials

Metal

Vertical Progressive Cavity Pump

Max. Temp

150C

Max. Head

120m

Max. flow

110m/hr

Materials

Metal

Hygienic Progressive Cavity Pump

Max. Temp

150C

Max. Head

480m

Max. flow

110m/hr

Materials

Metal

Industrial Progressive Cavity Pump

Max. Temp

150C

Max. Head

480m

Max. flow

110m/hr

Materials

Metal

Industrial Grinder

Max. Temp

- C

Max. Head

- m

Max. flow

100m/hr

Materials

Metal

Industrial Wobble Pump

Max. Temp

80C

Max. Head

40m

Max. flow

14.4m/hr

Materials

Metal

Flanged Progressive Cavity Pump

Max. Temp

150C

Max. Head

240m

Max. flow

2.7m/hr

Materials

Metal

Biogas Hopper Pump

Max. Temp

150C

Max. Head

240m

Max. flow

45m/hr

Materials

Metal

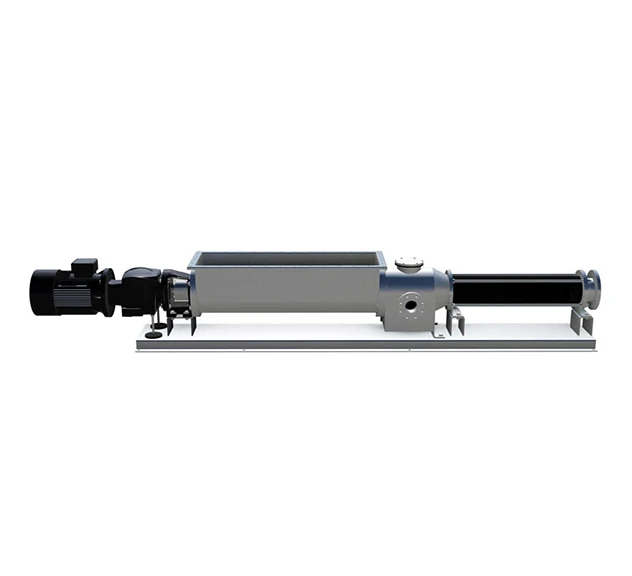

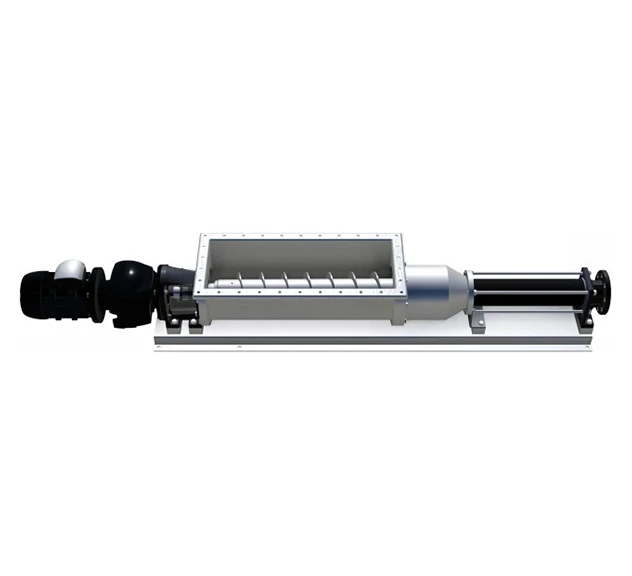

Auger Feed Screw Hopper Pump

Max. Temp

150C

Max. Head

240m

Max. flow

45m/hr

Materials

Metal

Double Shaft Hopper Pump

Max. Temp

150C

Max. Head

240m

Max. flow

315m/hr

Materials

Metal

If you have any further questions, our pump specialists will have the answer. Please don't hesitate to get in touch:

This pump is fully adaptable to your needs, offering customisation for mobility, mounting, and accessories, compliant with industry and safety standards. Provide your details below, and we’ll tailor a solution for you.