Our Centrifugal Pumps use a rotary impeller system, they are self-priming & ATEX-available, they are easy to install and have various configurations.

Industrial Centrifugal Pump

Hygienic Centrifugal Pump

High Performance Centrifugal Pump

EHEDG Sanitary Centrifugal Pump

Mechanically Sealed Plastic Centrifugal Pump

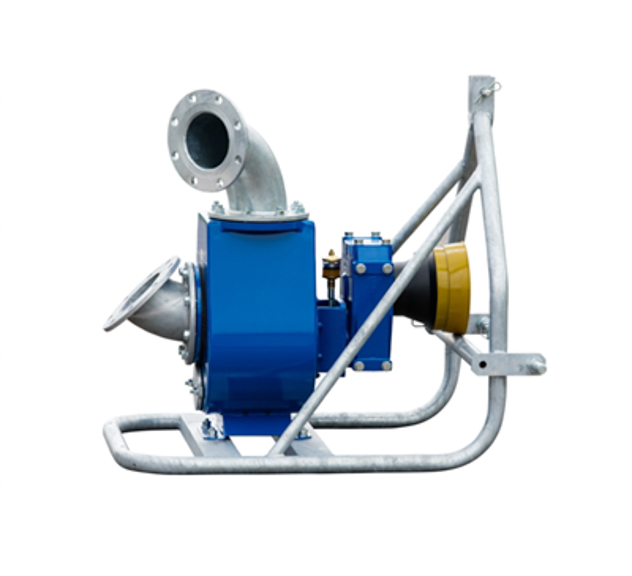

BBA Self Priming Centrifugal Pump

Industrial Self Priming Centrifugal Pump

Hygienic Self Priming Centrifugal Pump

Sanitary Self Priming Centrifugal Pump

Sanitary Liquid Ring Pump

PP & PVDF Immersion Centrifugal Pump

Stainless Steel Immersion Centrifugal Pump

Close Coupled Liquid Ring Pump

B300 T3WGT High-Flow Pump

BE160 D254 Multi-Use Pump

B140 T3WR Tractor-Driven Pump

B100 BVGMC Multi-Use Pump

B85 BVGMC Multi-Use Pump

B70-4 BVGMC Manure Pump

B70 BVGMC Multi-Use Pump

B58 BVGMC Multi-Use Pump

B50 BVGMC Multi-Use Pump

B45 BVGMC Multi-Use Pump

B30-180 BVGMC Multi-Use Pump

BA400G D500 High-Flow Pump

BA400G D540 High-Flow Pump

BA160L D420 High-Flow Pump

BA80H D275 High-Head Pump

Metal Magnetic Drive Centrifugal Pump

Magnetic Drive Stainless Steel Centrifugal Pump

Plastic Magnetic Drive Centrifugal Pump

Moulded Plastic Centrifugal Pump