EUROPE

ASIA & PACIFIC

Filter Results

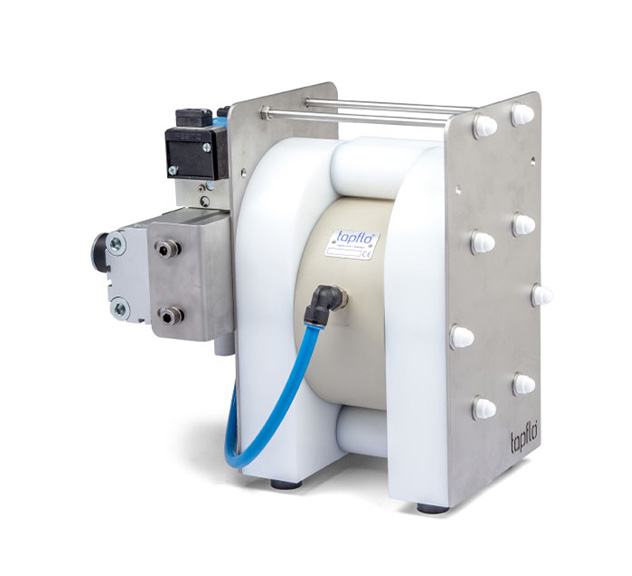

Diaphragm Pumps, one of the most commonly used pump types on the market today, are Positive Displacement Pumps that use two sets of internal diaphragms, constructed from PTFE or rubber, that work simultaneously to create pressure to push fluid through the pump.

All Tapflo Diaphragm Pumps use no-nut, clean-face diaphragms to ensure that no liquid can penetrate the diaphragm and are built with 70% fewer parts than other AODs on the market today. Some key benefits of using Diaphragm Pumps are:

To choose the appropriate Diaphragm Pump for your application, ask yourself the following questions:

Some of our materials offer an ATEX option on request for explosive applications and environments.

Depending on the size of your pump and the fluid you are pumping, a more detailed maintenance schedule may be required.

Will your pump be stationary, or do you need it to be portable? If you require portability, Diaphragm Pumps can be fitted to trolleys of any size to suit your needs.

Will you require additional accessories for your pump? Diaphragm rupture protection, level controllers, pulsation dampeners, and many other accessories to improve the performance of your pump even further are available.

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

100°C

Material:

Plastic

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

110°C

Material:

Metal

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

110°C

Material:

Metal

Max. Flow:

34m³/hr

Max. Head:

80m

Max. Temp:

100°C

Material:

Plastic/Metal

Max. Flow:

34m³/hr

Max. Head:

80m

Max. Temp:

100°C

Material:

Metal

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

70°C

Material:

Plastic

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

110°C

Material:

Metal

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

N/A

Material:

Metal

Max. Flow:

30m³/hr

Max. Head:

80m

Max. Temp:

110°C

Material:

Metal

Max. Flow:

34m³/hr

Max. Head:

80m

Max. Temp:

70°C

Material:

Plastic/Metal

Max. Flow:

13m³/hr

Max. Head:

40m

Max. Temp:

110°C

Material:

Plastic/Metal

Max. Flow:

34m³/hr

Max. Head:

160m

Max. Temp:

110°C

Material:

Plastic/Metal

Max. Flow:

6.6m³/hr

Max. Head:

80m

Max. Temp:

110°C

Material:

Plastic/Metal

Max. Flow:

49m³/hr

Max. Head:

80m

Max. Temp:

110°C

Material:

Plastic/Metal

Max. Flow:

N/A

Max. Head:

N/A

Max. Temp:

N/A

Material:

Plastic/Metal

Our friendly team at Tapflo UK would be more than happy to assist you further with any pump solutions, delivery information or questions you have. If you need additional support on-site, you can speak to a member of the team today to organise a site visit.

Give us a call now:

Search our pump support articles: