Understanding Sanitary Pumps

What are Sanitary Pumps?

Sanitary Pumps are specialised pieces of equipment designed to meet the stringent hygiene and regulatory requirements of industries like Cosmetics, Pharmaceuticals and Food & Beverage. Unlike standard pumps, these are crafted with materials, such as Stainless Steel 316, that eliminate the risk of contamination during the pumping process.

3 Key Features of Sanitary Pumps:

- For Cosmetics manufacturing, it’s imperative to use pumps with either FDA approval or certification from EHEDG (European Hygienic Engineering and Design Group). These certifications ensure that the pump materials and design adhere to strict sanitary standards

- Sanitary Pumps, especially those used in the Cosmetics industry, are typically constructed from materials like Stainless Steel AISI 316L. This choice of material not only ensures durability but also facilitates easy cleaning and maintenance

- Unlike standard pumps, Sanitary Pumps feature a design that minimises potential areas for bacteria growth. For instance, in Diaphragm Pumps, clean, no-nut face diaphragms are employed, eliminating leakage points and areas conducive to bacterial development

The Role of Sanitary Pumps in Cosmetics Manufacturing

- Preventing Contamination: in the Cosmetics industry, where products come in direct contact with the skin or are ingested, the prevention of contamination is critical! Sanitary Pumps play a vital role in maintaining the purity of formulations by eliminating the risk of bacterial growth or foreign particle contamination

- Ensuring Compliance: regulatory bodies demand strict adherence to hygiene and safety standards in Cosmetics manufacturing. The use of FDA-approved or EHEDG-certified Sanitary Pumps becomes non-negotiable to ensure compliance with these standards

- Preserving Product Integrity: whether it’s pumping toothpaste, shampoos, lotions or perfumes, the integrity of the product must be preserved throughout the manufacturing process. Sanitary Pumps, with their hygienic design and material selection, safeguard the quality and efficacy of cosmetic formulations

- Versatility for Various Products: the Cosmetics industry encompasses a diverse range of products with different viscosities and characteristics. Sanitary Pumps, such as our Sanitary and Aseptic (EHEDG) Diaphragm Pumps, Sanitary Lobe Pumps and Peristaltic Pumps, offer versatility to handle products like creams, shampoos and even viscous fluids like face scrubs

Cosmetic Applications Examples

- Toothpaste

- Shampoo & conditioners

- Moisturisers and lotions

- Perfume

- Face scrubs

- Medicines

- Bath bombs

- Mouthwash

- Makeup

…and so much more!

Tapflo UK's Range of Sanitary Pumps

FDA-approved, ATEX-rated Air Operated Sanitary Diaphragm Pump designed for the Cosmetics, Food, Beverage and Pharmaceutical industries. Featuring customisable options for solids, it offers self-priming capabilities, flow rates up to 820 l/min, handles solids up to 100m and viscosities of 200+ cSt, discharge pressures up to 8 Bar and is CIP/SIP capable.

Aseptic Diaphragm Pump (EHEDG Certified):

EHEDG Certification ensures this pump conforms to the highest hygiene standards. With flows up to 330 l/min, discharge pressures up to 8 Bar, solids-handling up to 10m and viscosities up to 200 cSt, as well as ATEX-rating and self-priming capabilities, this pump guarantees optimal performance. Additionally, this pump can be easily rotated to facilitate drainage during CIP/SIP processes.

A versatile Sanitary solution for the Cosmetics, Food and Pharmaceutical industries. EHEDG-certified with CIP/SIP capabilities, this pump upholds the highest hygiene standards. Crafted from Cast Stainless Steel AISI 316L for superior corrosion resistance while the Duplex Stainless Steel 1.4462 shafts ensure added rigidity. ATEX-available, solids passage up to 60mm. With interchangeable sealing options, this pump can accommodate various needs. Can be mounted horizontally or vertically, providing self-draining capabilities when mounted vertically.

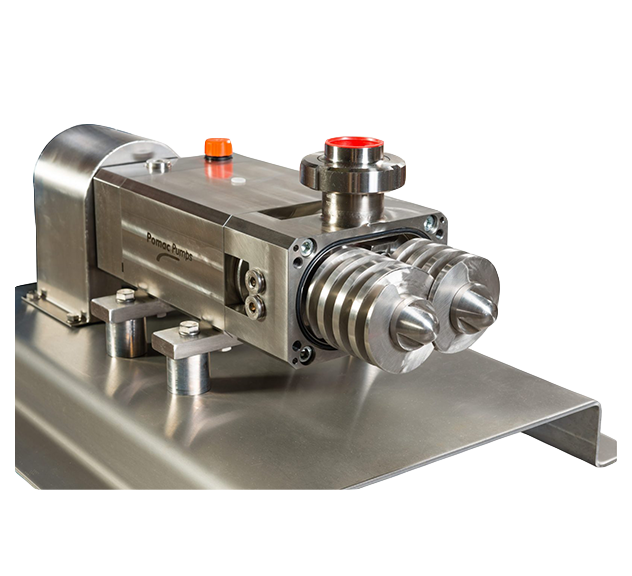

A versatile Positive Displacement Pump for the Hygienic Processing industry. Unlike Gear Pumps, the LPX’s non-contacting lobes offer advantages for specific media, ensuring clean and hygienic operation. Ideal for gentle pumping of low and high-viscosity products, thus minimising shear forces. Energy-efficient design with special rotor-shaft mounting for accurate positioning and backlash-free connection. Unique gear housing eliminates cross-contamination with gear oils. Bi-directional flow, horizontal and vertical mounting options, 8 sizes available with a max particle size of up to 15mm. CIP/SIP suited, FDA-approved food contact materials and fully CE compliant for reliable operation.

EHEDG-compliant for hygienic applications within the Cosmetics, Food and Pharmaceutical industries. Crafted from high-grade Cast Stainless Steel, this self-priming Double Screw Pump offers superior corrosion resistance with a surface finish of <0.8 Ra (upgradeable to <0.5). Pulsation-free pumping of thin to highly viscous fluids (up to 1,000,000 cPs) and large free passage of solids up to 60mm. CIP/SIP friendly with various sealing options and elastomer materials available to suit your requirements.

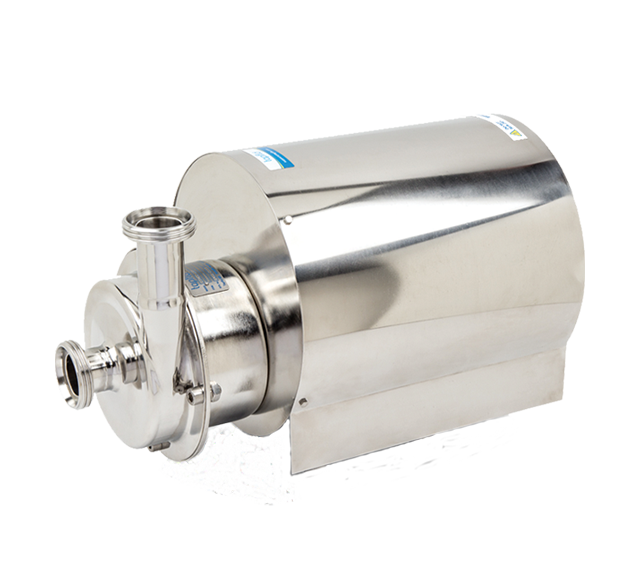

CTX-H High-Performance Centrifugal Pump:

Ideal for low to medium-viscosity fluids with suspended solids. Featuring hygienic connections with DIN 11851 as standard this pump ensures cleanliness within your operation. With a modular design, adaptable to various applications and installation conditions, the CTX-H offers flow rates up to 132m³/hr, heads up to 80m and max temperature handling up to 120°C. ATEX-available for use in hazardous environments.

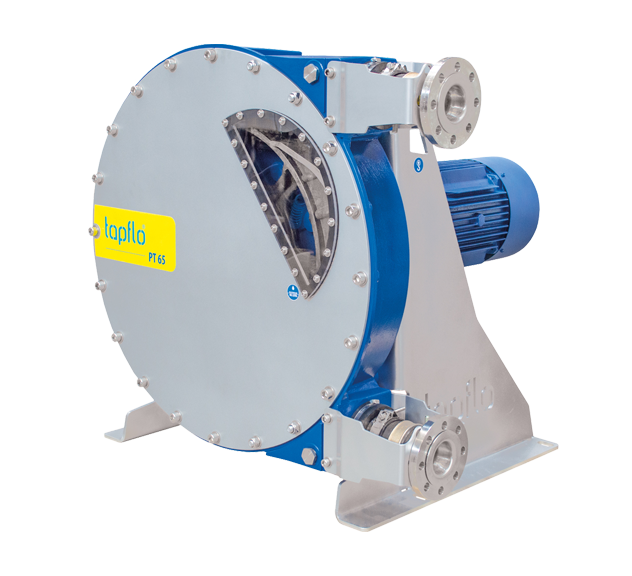

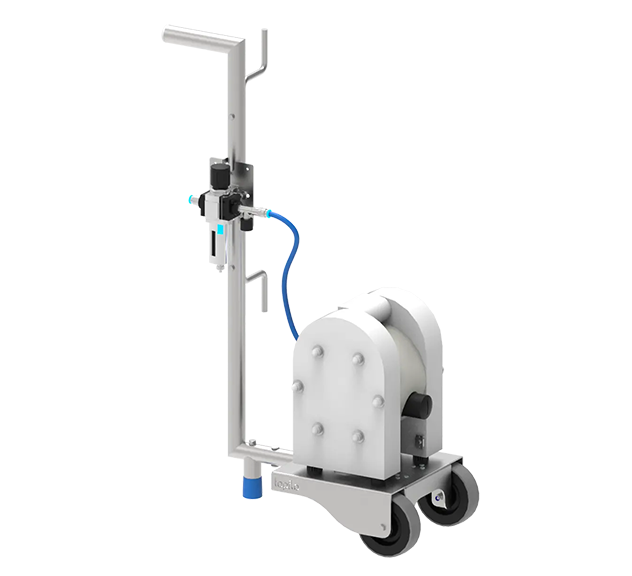

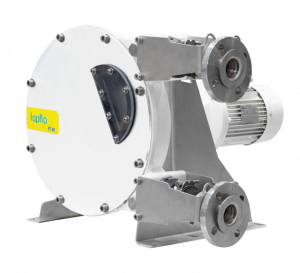

PTL Low pressure Peristaltic Pump:

Featuring a roller design, food-approved silicone grease lubricant and aluminium housing for safe and hygienic operation, with horizontal and vertical motor positions for added versatility. The ATEX-rated PXTL variant of this pump ensures safety in hazardous environments. Efficient self-priming with a suction capacity up to -0.6 Bar, capable of handling viscosities up to 100,000 cPs. Available in 6 sizes, well-suited for pumping highly abrasive, corrosive and viscous liquids with solids.

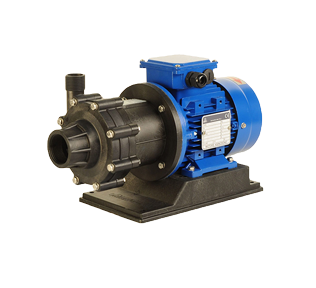

A highly efficient solution designed for the Cosmetics, Food, Beverage and Pharmaceutical industries. Equipped with FDA & EN1935 certified hoses, sanitary clamp and thread connections, ensuring exceptional performance and hygienic standards. The sealless design minimises liquid contact with only 2 liquid-contact parts. Featuring an innovative CIP shoe design and using glycerin FDA as the lubricant, this pump can be delivered in a range of sizes to suit critical applications requiring cleanliness and precision. ATEX-rated for use in hazardous environments.

Based on our standard Air-Operated Diaphragm Pump (AODD), the Sanitary Powder Pump is an economical and compact alternative to complex powder system. Designed for both industrial and sanitary powders, it offers portability and convenience. Tapflo UK conducts trials with your application to ensure seamless operation with powders. Delivers flows up to 49m³/hr and discharge pressures up to 80m. ATEX-rated for use in hazardous environments.

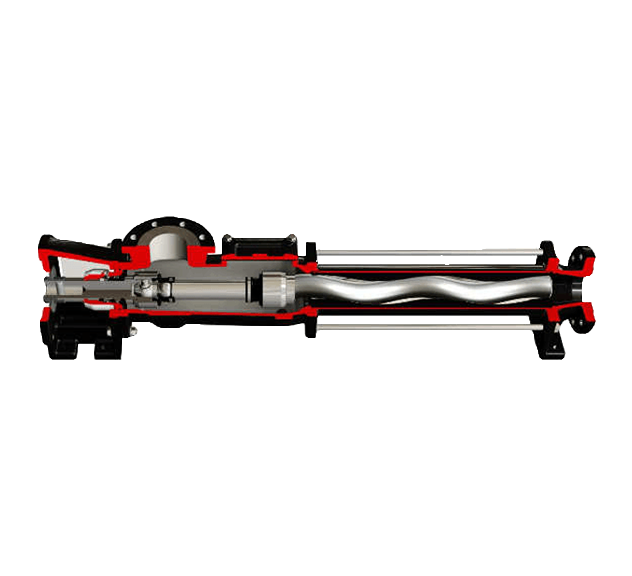

Hygienic Progressive Cavity Pump:

Constructed with Stainless Steel and available in 6 different models, these pumps have been designed for efficient drainage and eliminating dead zones. Equipped with CIP/SIP functionality, these 3A and EHEDG-certified pumps ensure optimal cleanliness and strict compliance with Sanitary standards. Additionally, they deliver self-priming capabilities up to 7m, block construction or bearing housing with independent shaft, a wide range of connection options as well as ATEX-rating for use in hazardous environments.

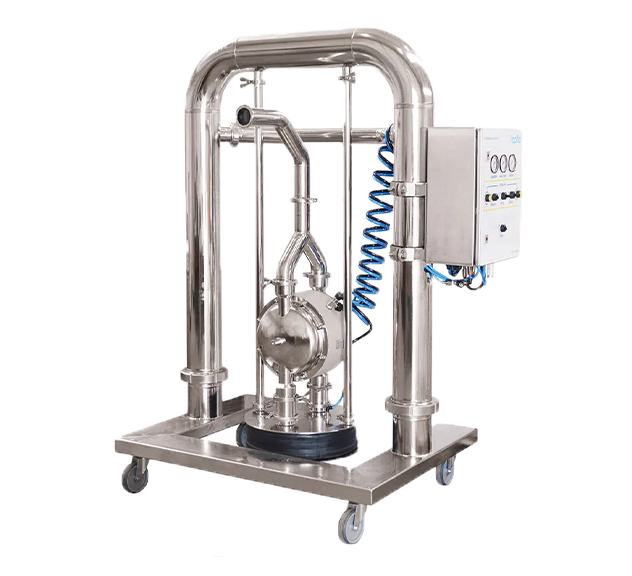

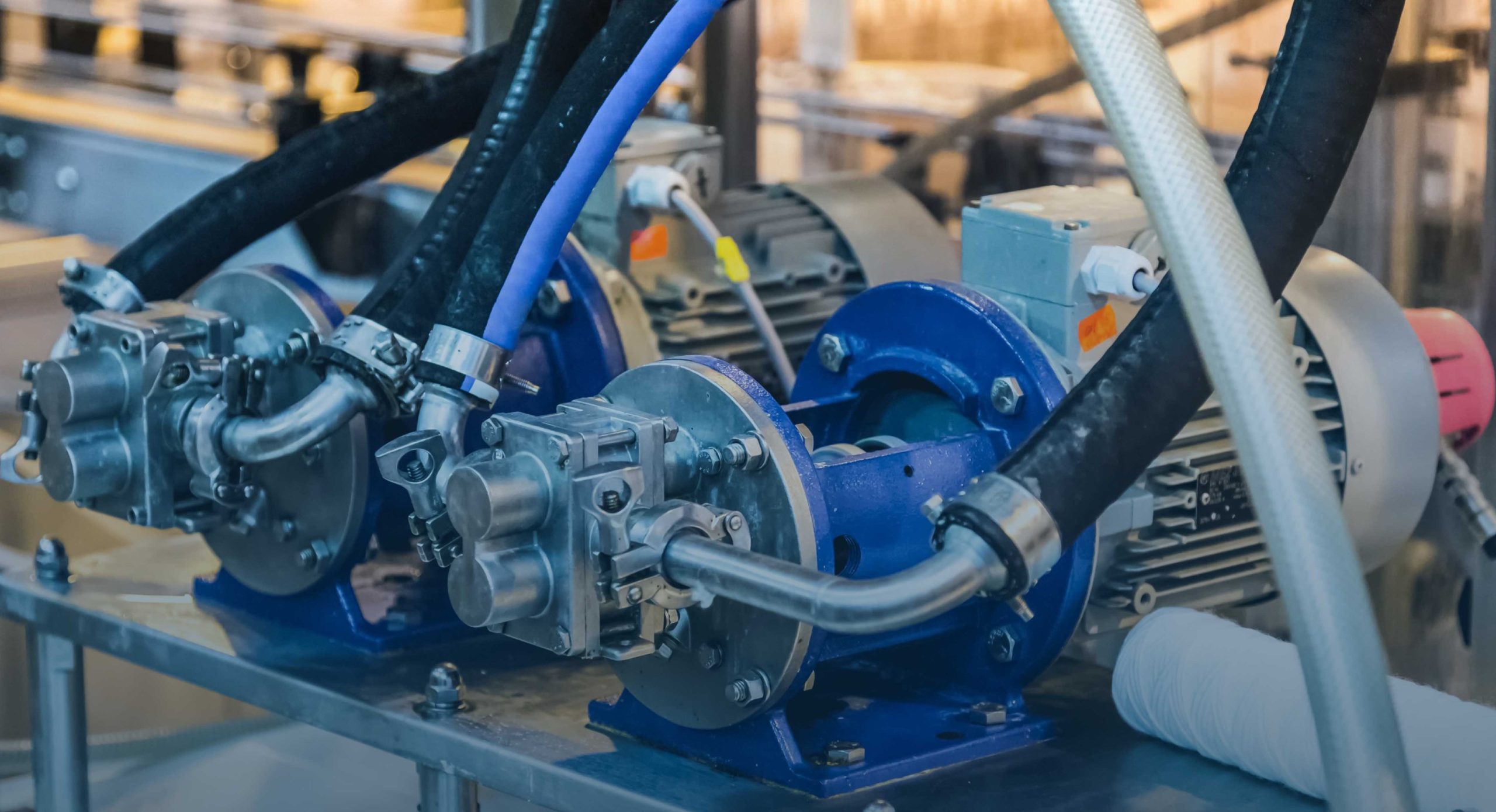

SLES Mixing & Dilution Pump System:

For those in the Cosmetics and Pharmaceutical industries looking for more than just a pump, our SLES Mixing & Dilution Unit could be the solution for you. Our SLES Unit is ideal for companies pumping shampoo products, face washes, soaps and all other products containing SLES (Sodium Lauryl Ether Sulphate) who want to save money by diluting SLES themselves.

Featuring a Progressive Cavity Pump responsible for feeding the 70% concentrated SLES solution and a Centrifugal Pump for expertly mixing the SLES with water while pumping the final solution, this system empowers operators with precise control over the dilution process. This ensures immediate and accurate preparation of a less concentrated SLES solution tailored to your exact specifications.

Additional features of the SLES Mixing & Dilution System:

- Various sizes available

- Discharge pressures up to 6 Bar

- Pipework constructed from durable AISI 316 Stainless Steel

- Frame built from AISI 304 Stainless Steel for structural support

- Control and automation features integrated for seamless operation

Read more about our SLES Mixing & Dilution Pump System here.

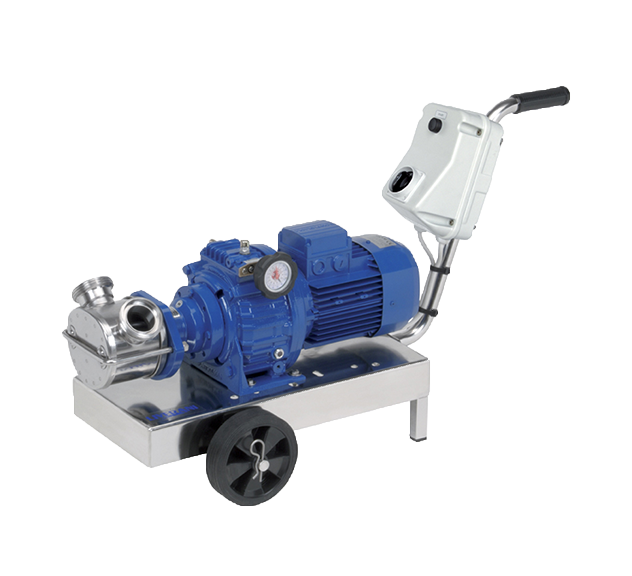

Additionally, for added portability and versatility, our Sanitary Pumps can be added onto our range of Hygienic Trolleys. These trolleys are constructed from Stainless Steel with removable handles for convenient transportation. Furthermore, these ATEX-available trolleys are also available with a host of accessories including On/Off Switches, Frequency Inverters and Hose Holders.

Benefits of Using Sanitary Pumps

Here’s a list of benefits highlighting the advantages of using Sanitary Pumps in the Cosmetics industry:

- Sanitary Pumps adhere to the strictest hygiene standards

- Our Sanitary Pumps come with FDA approval or EHEDG certification, providing assurance of product safety

- The design of Sanitary Pumps minimises the risk of contamination, crucial for cosmetic products intended for direct skin contact or consumption

- Sanitary Pumps are crafted from materials like Stainless Steel AISI 316L, enhancing durability and corrosion resistance

- Clean, no-nut face diaphragms in Sanitary Diaphragm Pumps eliminate potential leakage points and smooth surfaces prevent bacterial growth

- Sanitary Pumps, including Diaphragm, Lobe and Peristaltic Pumps, offer versatility to handle a diverse range of cosmetic products with varying viscosities

- Sanitary Pumps play a crucial role in preserving the quality and efficacy of cosmetic formulations

- Specifically designed pumps, like Lobe Pumps and Twin Screw Pumps, are ideal for handling viscous cosmetic products such as creams and shampoos

- Sanitary Pumps support Clean In Place (CIP) and Sterilisation In Place (SIP), ensuring thorough cleaning and sterilisation for sanitary applications

- The design of Sanitary Pumps minimises areas where bacteria could grow, enhancing the overall safety and quality of cosmetic products

- Sanitary Pumps are designed for easy disassembly and cleaning, simplifying maintenance procedures and minimising downtime

- In specific cases, such as with the SLES Mixing & Dilution Unit, Sanitary Pumps offer cost-effective solutions for diluting concentrated surfactants, like Sodium Lauryl Ether Sulphate

Tips for Choosing the Right Sanitary Pump

- Application Compatibility: ensure the pump is suitable for your application, taking into account the type of fluids, viscosity and any special requirements of your industry

- Material Construction: choose pumps constructed from high-quality and corrosion-resistant materials such as Stainless Steel (e.g., AISI 316L)

- Surface Finish: look for pumps with a smooth surface finish, typically with low roughness (e.g., <0.8 Ra), to minimise bacterial adhesion and facilitate effective cleaning

- Hygienic Design: choose pumps with a hygienic design that minimise dead spaces and crevices where fluids or contaminants could accumulate

- Certifications: check for industry certifications such as EHEDG (European Hygienic Engineering & Design Group) or FDA compliance to ensure the pump meets strict hygiene and safety standards

- CIP/SIP Capabilities: opt for pumps with Clean-In-Place (CIP) and Sterilization-In-Place (SIP) capabilities

- Sealing Options: look for pumps with interchangeable sealing options

- Self-Draining Features: consider pumps with self-draining features, especially if they are vertically mounted

- Connection Types and Sizes: look at the available connection types and sizes (e.g. Tri-Clamp, threaded, DIN, BSP) to ensure compatibility with your system and to facilitate easy integration

- Ease of Maintenance: look at the pump’s design for ease of disassembly and maintenance

- Supplier Reputation choose reputable suppliers with a track record of providing reliable and high-quality Sanitary Pumps

Dedicated Case Study

To see our Sanitary Pumps in action, take a look at our dedicated Case Study below where we supported an up-and-coming cosmetics company specialising in face scrubs.

Faced with the challenge of efficiently transferring their peppermint face scrub from a 1000l Stainless Steel tank to a filling line, they sought a reliable and precise pumping solution.

Application Details:

- Fluid: Peppermint face scrub

- Viscosity: 1000 cPs

- Flow Rate: 100 l/per min

- Temperature: Ambient

- Solids: Some 1mm chunks

- Pipe Work: 1 1/2”

- Length of Discharge: 6m flexi hose

- Suction Condition:5m vertical, 2m across

- Pump Solution Provided: Sanitary Diaphragm Pump

- Pump Type: T125 STT Diaphragm with remote stop-start unit

- Materials: Stainless Steel and PTFE

- Accessories: Tapflo remote Pneumatic Start/Stop Units

- Connection Size: 1 ½”

The Sanitary Diaphragm Pump proved instrumental in meeting the cosmetics company’s unique requirements. The pump, crafted from Stainless Steel and PTFE, provided the necessary durability and compatibility with the peppermint face scrub.

The successful implementation of the Sanitary Diaphragm Pump solution resulted in increased customer satisfaction. Delighted with the pump’s performance, this company has since purchased 3 additional pumps to support their growing production needs.

Conclusion

In conclusion, Sanitary Pumps are not just components; they are guardians of quality and compliance in Cosmetics manufacturing. By prioritising hygiene, preventing contamination and ensuring regulatory adherence, these pumps contribute significantly to the reliability and success of the entire cosmetics production process.

If you are facing similar challenges in fluid handling within your factory or require a reliable pump solution tailored to your specifications, reach out to Tapflo. Contact us at 023 8025 2325 or email [email protected].