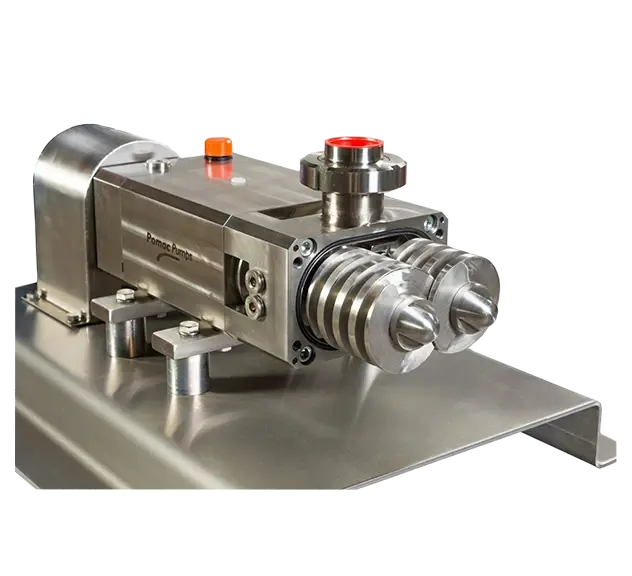

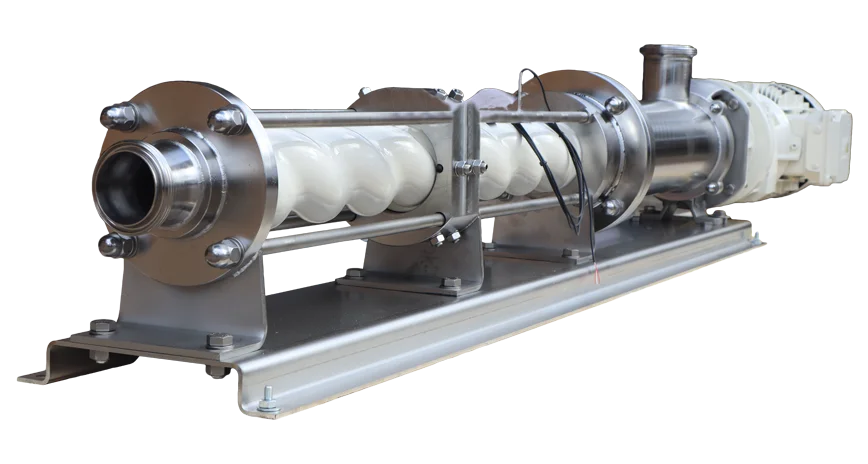

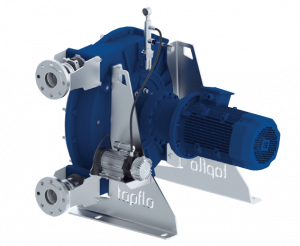

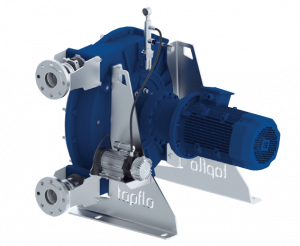

Our Low Pressure Peristaltic Pump is an efficient and versatile pumping solution designed to deliver consistent performance while ensuring product integrity and hygiene standards are maintained. This low-pressure pump is well-suited to pumping highly abrasive, corrosive and viscous liquids containing solids. Featuring a roller design, food-approved silicone grease lubricant, and aluminium housing, these pumps ensure safe and hygienic operation. Horizontal and vertical motor positions are available for increased versatility. Additionally, if you operate in hazardous environments, the PXTL, which is the ATEX-rated low-pressure version of this pump, ensures the utmost safety and peace of mind in these environments.

Typical applications for our Low Pressure Peristaltic Pump:

Overview

Features & Benefits

Specifications

Variations

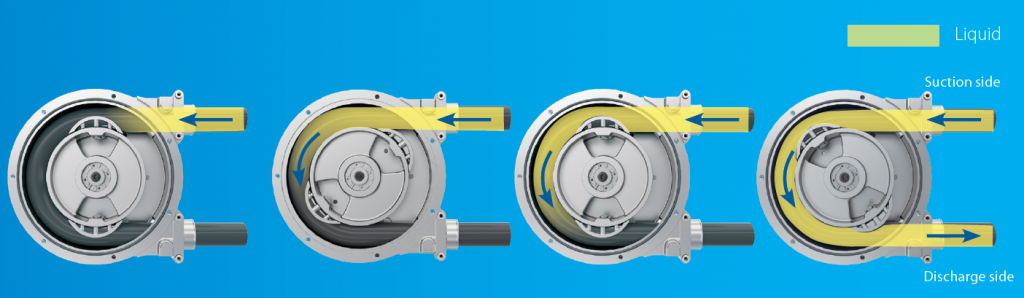

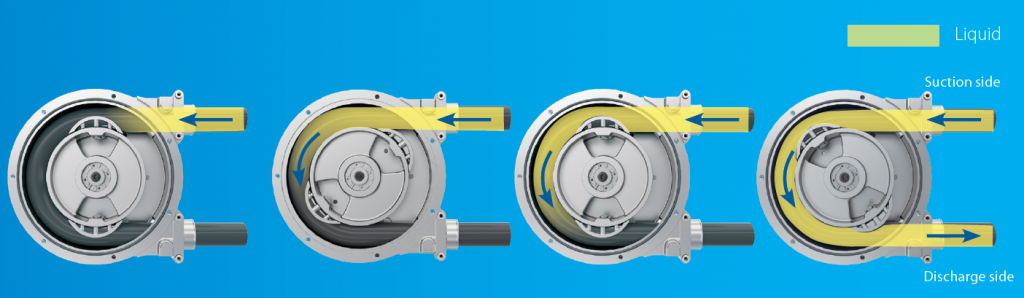

The PTL Low Pressure Peristaltic Pump features a roller design which is highly effective for discharge pressures up to 4 Bar. The friction on the hose with rollers is lower which is why the hose needs to be lubricated by silicone grease. The rollers can be adjusted by brackets or shims depending on the pump size:

Moreover, our hoses last around 30% longer than any hoses on the market today, and are characterised by their non-machined external surface, a feature that enhances the lubrication of these reinforced hoses.

- Pump challenging liquids: Peristaltic Pumps are ideal for pumping highly abrasive, corrosive and viscous liquids containing particles

- Reduced downtime: Hassle-free maintenance and minimal downtime thanks to few components and no seals required

- Easy operation: User-friendly operation without the need for specialised personnel

- Cost-effective solution: Total cost of ownership for economical pumping solutions

- Turbulence-free performance: Smooth and gentle pumping even with highly abrasive or sensitive liquids, minimising wear and ensuring optimal operations

- Extensive configuration options: Customise your pump connection with a range of types and orientations

- Self-priming: Efficient self-priming with superior suction capacity up to -0.9 Bar

- Handling high viscosity: Reliable performance with the ability to pump liquids with viscosities up to 100,000cP

- Reversible operation: Versatile functionality for various applications with an easy change of rotation direction

- Adjustable flow and precise dosing: Flexibility in flow rates and precise dosing accuracy of approximately ±5% by adjusting the speed, such as with a frequency inverter

- Safe to run dry: Safe to run dry, eliminating the need or monitoring and ensuring ease of use and peace of mind

| Technical Data |

Specification |

| Casing Material |

Aluminium |

| Hose Material (wetted) |

Industrial reinforced – NR (std), NBR, EPDM, CSM

ATEX reinforced – NR, EPDM

Food grade reinforced – NR FDA, NBR FDA, EPDM FDA

Extruded hose – Silicone |

| Insert Material (wetted) |

AISI 316L (std), PTFE, HDPE AST, PP |

| Connection Type |

Hose tail (std), EN1092-1 Flange, ANSI flange, BSP/NPT thread, Camlock, DIN 32676 clamp, DIN 11851 thread, SMS 3017 clamp |

| Motor* |

IEC standard, 3-phase, 4-pole, 50/60 Hz, IP55+PTC |

| Max Capacity |

5m3/h |

| Max Viscosity |

12 000 cP*** |

| Max Liquid Temperature |

80 ºC** |

| Max Discharge Pressure |

4 Bar (with reinforced hose) |

| Max Suction Lift |

-0.9 Bar |

*Other motor options available on request

**At a room temperature of 20°C. Furthermore, it depends on the pumped fluid and on the hose material

***Maximum value may vary depending on pump size and installation

Available Hose Materials:

| Hose |

ATEX |

Industry |

| Water Treatment |

Ceramic |

Mining & Quarries |

Building & Construction |

Chemical |

Food & Beverage |

Pharma & Cosmetics |

Print, Pulp & Paper |

Agriculture & Biogas |

| Industrial |

| NR |

X |

X |

X |

X |

X |

X |

|

|

X |

X |

| NBR |

|

X |

|

X |

|

X |

|

|

|

X |

| EPDM |

X |

X |

X |

X |

X |

X |

|

X |

X |

X |

| CSM |

|

X |

|

X |

|

X |

|

|

|

X |

| Food Grade |

| NR FDA |

|

|

|

|

|

|

X |

X |

X |

|

| NBR FDA |

|

|

|

|

|

|

X |

X |

|

|

| EPDM FDA |

|

|

|

|

|

|

X |

X |

|

|

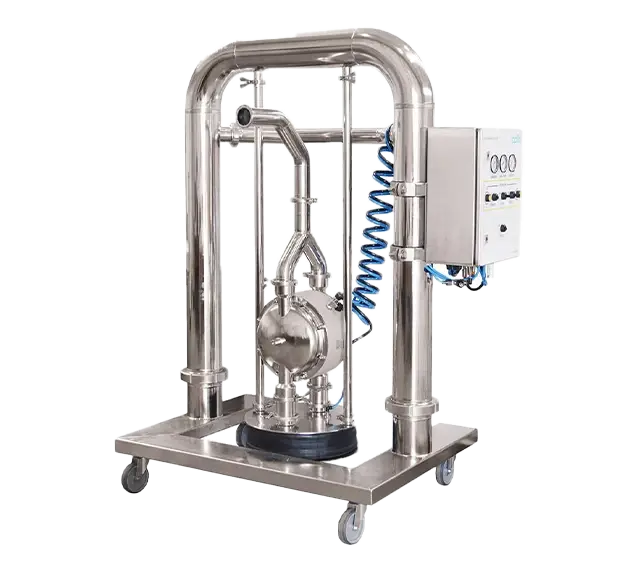

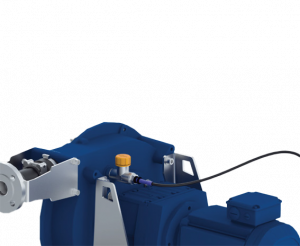

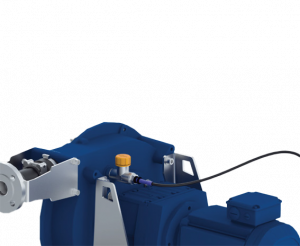

- DPT Pulsation Dampener

- Hose Leak Detector (HLD)

- Built-In Frequency Inverter

- Revolution Counter (RC)

- Vacuum System

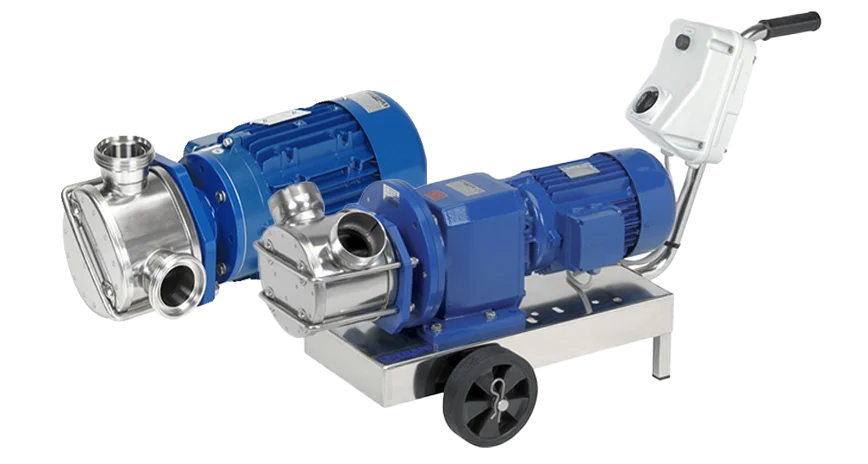

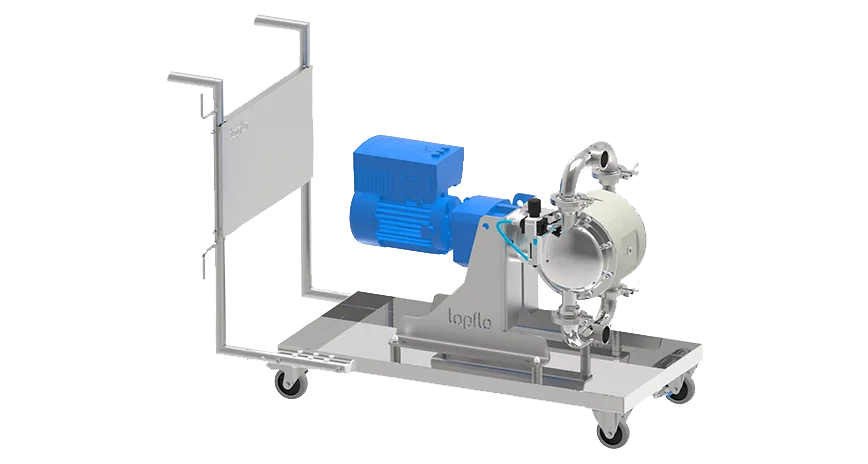

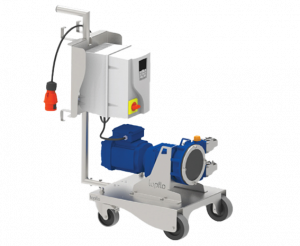

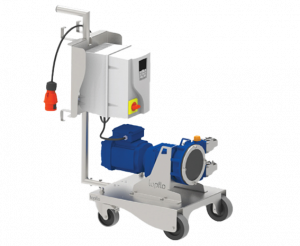

- Trolleys

- DPT Pulsation Dampener

- Hose Leak Detector

- Built-in Frequency Inverter

- Revolution Counter

- Vacuum System

- Trolleys