| Model | Max Solids Passage (mm) | Max Pressure (Bar) |

|---|---|---|

| PLP 1-¾ | 13 | 15 |

| PLP 1-1 | 13 | 15 |

| PLP 1-1.5 | 13 | 15 |

| PLP 1.5-2 | 22 | 8 |

| PLP 2-1.5 | 23 | 15 |

| PLP 2-2 | 23 | 15 |

| PLP 2-2.5 | 23 | 15 |

| PLP 3-2 | 37 | 15 |

| PLP 3-3 | 37 | 15 |

| PLP 3-4 | 37 | 15 |

| PLP 4-4 | 52 | 15 |

| Model | Max Solids Passage (mm) | Max Pressure (Bar) |

|---|---|---|

| PLP 1-¾ | 13 | 15 |

| PLP 1-1 | 13 | 15 |

| PLP 1-1.5 | 13 | 15 |

| PLP 1.5-2 | 22 | 8 |

| PLP 2-1.5 | 23 | 15 |

| PLP 2-2 | 23 | 15 |

| PLP 2-2.5 | 23 | 15 |

| PLP 3-2 | 37 | 15 |

| PLP 3-3 | 37 | 15 |

| PLP 3-4 | 37 | 15 |

| PLP 4-4 | 52 | 15 |

Download Brochure

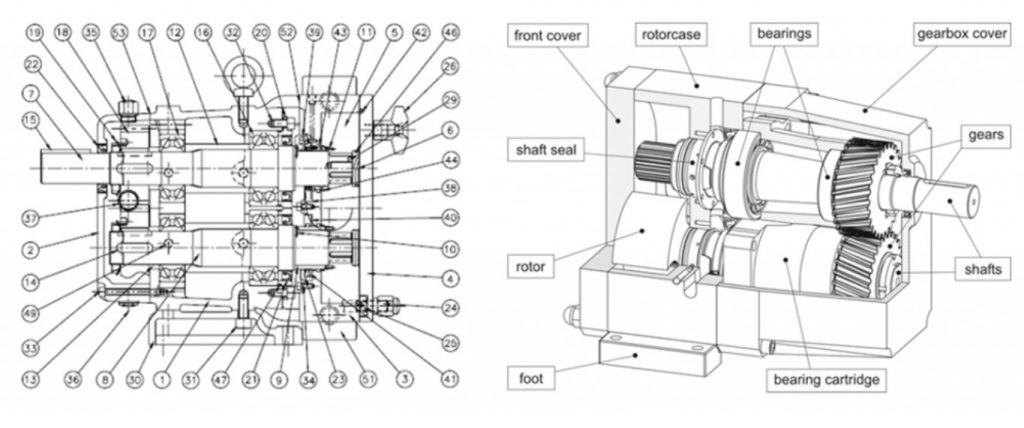

Our EHEDG Lobe Pump is a Sanitary Lobe Pump produced specifically for hygienic and sanitary applications within the food, chemical, and pharmaceutical industries. The series is fully compliant with EHEDG standards and has been designed with a heavy emphasis on achieving maximum performance & efficiency whilst offering compactness, robustness, cleanability & low maintenance costs thanks to its front pull-out design. The Lobe Pump range consists of 11 pump sizes, depending on the flow and solids passage requirements. Similarly to other pumps in Pomac’s range, this Pump is entirely machined from cast Stainless Steel AISI 316L with a surface roughness of <0.8 as standard (<0.5 on request) to provide increased corrosion resistance.

Competitors’ units employ a cast iron gearbox with epoxy paint which can become eroded over time and need replacing/repairing. These Lobe Pump shafts are constructed from Duplex Stainless Steel 1.4462 to provide extra rigidity in operation. The pump can be fitted with several different sealing options and elastomer materials to suit almost any application.

With capacities up to 110 m³/hr and discharge pressures up to 15 Bar, this range of Sanitary Lobe Pumps is suitable for various applications. This, coupled with some key features and benefits, puts it apart from its competition as one of the most versatile Lobe Pumps on the market today. With the delivery of each product, the customer receives a lobe rotor tool and dummy rotors to facilitate easy removal and replacement of lobes and mechanical seals, further reducing downtime.

Our EHEDG Lobe Pump is a Sanitary Lobe Pump produced specifically for hygienic and sanitary applications within the food, chemical, and pharmaceutical industries. The series is fully compliant with EHEDG standards and has been designed with a heavy emphasis on achieving maximum performance & efficiency whilst offering compactness, robustness, cleanability & low maintenance costs thanks to its front pull-out design. The Lobe Pump range consists of 11 pump sizes, depending on the flow and solids passage requirements. Similarly to other pumps in Pomac’s range, this Pump is entirely machined from cast Stainless Steel AISI 316L with a surface roughness of <0.8 as standard (<0.5 on request) to provide increased corrosion resistance.

Competitors’ units employ a cast iron gearbox with epoxy paint which can become eroded over time and need replacing/repairing. These Lobe Pump shafts are constructed from Duplex Stainless Steel 1.4462 to provide extra rigidity in operation. The pump can be fitted with several different sealing options and elastomer materials to suit almost any application.

With capacities up to 110 m³/hr and discharge pressures up to 15 Bar, this range of Sanitary Lobe Pumps is suitable for various applications. This, coupled with some key features and benefits, puts it apart from its competition as one of the most versatile Lobe Pumps on the market today. With the delivery of each product, the customer receives a lobe rotor tool and dummy rotors to facilitate easy removal and replacement of lobes and mechanical seals, further reducing downtime.

Traditional Construction VS Advanced EHEDG Lobe Pump Construction

Traditional Construction Disadvantages

Advanced EHEDG Lobe Pump Construction Advantages

| Max Capacity | 110 m³/hr |

| Max Pressure | 150 meters (250 meters upon request) |

| Max Viscosity | <1’000’000 cPs |

| Max Temperature | 140ºC |

| Max Solids Passage | 60 mm – Model & Screw Type Specific |

| Lobes | Bi-Wing or Quattro Lobe |

| Connections | ¾” – 4” |

| Connection Types | Couplings: DIN11851, DIN11864-1, SMS1145 Flanges: EN1092-1, Rectangular, DIN11864-2, ANSI Tri-Clamps: ISO2852, DIN32676, DIN11864-3 |

| Shaft Sealing | Single mech. seal SIC/SIC or TC/TC Double mech. seal SIC/SIC or TC/TCWDR Lip Seal Single O-ring Double O-ring with quench |

| Sealing Materials | SiC / SiC or Tungsten / Tungsten |

| Elastomer Materials | EPDM, Viton, NBR, Teflon, KALREZ, e.g. according to FDA |

| Wetted Parts | AISI 316L (AISI 316L Mo Ni or Hastelloy CX2MW N26022 upon request) |

| Surface Roughness | <0.8 Micron (Std.), <0.5 upon request (Mechanical & Electro-Polished) |

| Hardening | Hard Inchromizing & Plasma Nitriding (Optional) |

| Drives | Standard: IEC, IE2, B3/B5, IP55, isolcl. F, PTC Optional: IE3, ATEX, CSA/UL, Decentralised variable speed drive |

Capacity Range

| Pump Model | Displacement Litres / 100 Rev | Max Solids Passage mm | Max Pressure Bar | Max Speed Rpm | Weight Kg |

| PLP 1-¾ | 4.2 | 13 | 15 | 1500 | 12 |

| PLP 1-1 | 6 | 13 | 15 | 1500 | 12.5 |

| PLP 1-1.5 | 10 | 13 | 15* | 1200 | 14 |

| PLP 1.5-2 | 20 | 22 | 8 | 1200 | 21 |

| PLP 2-1.5 | 22 | 23 | 15 | 1200 | 37 |

| PLP 2-2 | 30 | 23 | 15 | 1200 | 39 |

| PLP 2-2.5 | 36 | 23 | 15* | 1000 | 44 |

| PLP 3-2 | 55 | 37 | 15 | 1000 | 101 |

| PLP 3-3 | 100 | 37 | 15 | 1000 | 105 |

| PLP 3-4 | 130 | 37 | 15* | 750 | 115 |

| PLP 4-4 | 250 | 52 | 15 | 750 | 250 |

*Depends on the gap between the rotor and pump casing.

The values mentioned above are maximum values. The operational values may be lower because of the liquid characteristics of the system design.