That’s right, Tapflo UK can also supply Marine Pumps! Below is a list of frequently asked questions, followed by a case study to guide you through buying the correct pump for your needs. For more in-depth information and guidance, don’t hesitate to contact the team at Tapflo.

What types of Marine Pumps & Equipment can Tapflo supply?

Tapflo UK has a full and extensive range of Marine Pumps at their disposal ranging from the following types:

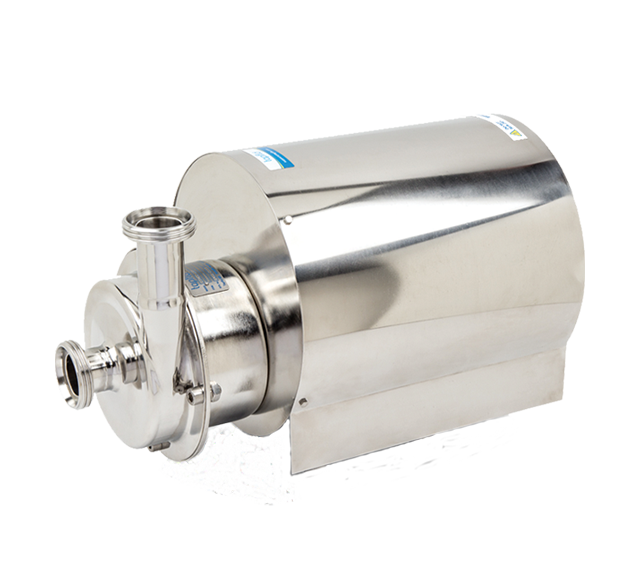

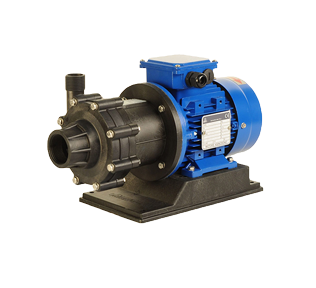

- Horizontal and In-Line Centrifugal Pumps (Single & Multistage)

- Split Casing Centrifugal Pumps (Vertical & Horizontal)

- Self-Priming Centrifugal Pumps

- Liquid Ring & Peripheral Pumps

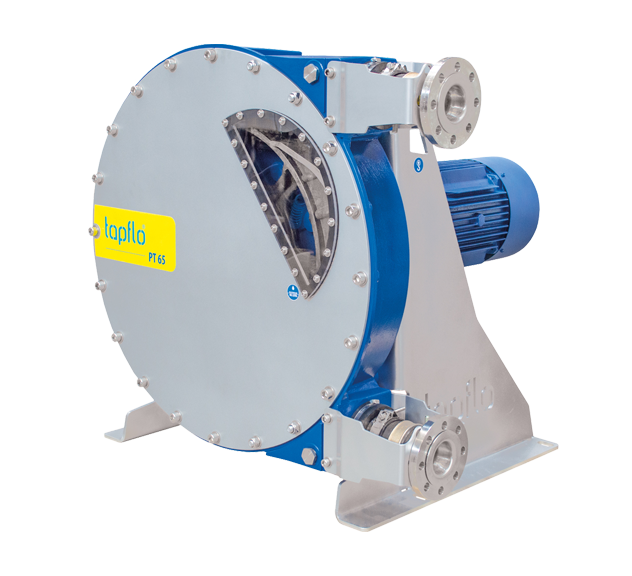

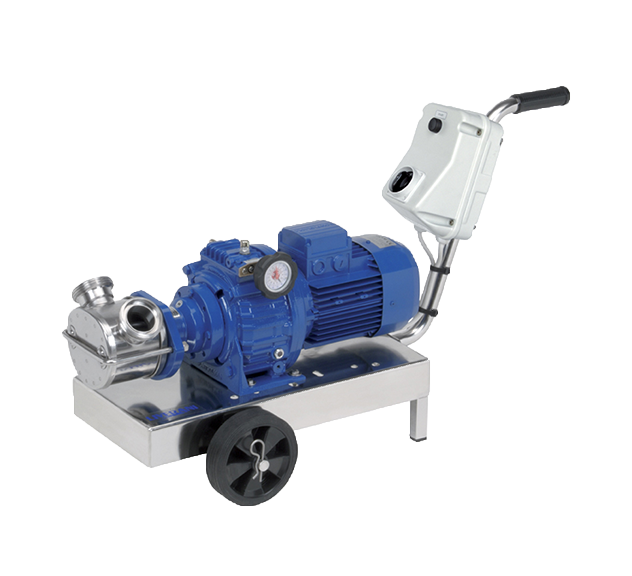

- Flexible Impeller Pumps

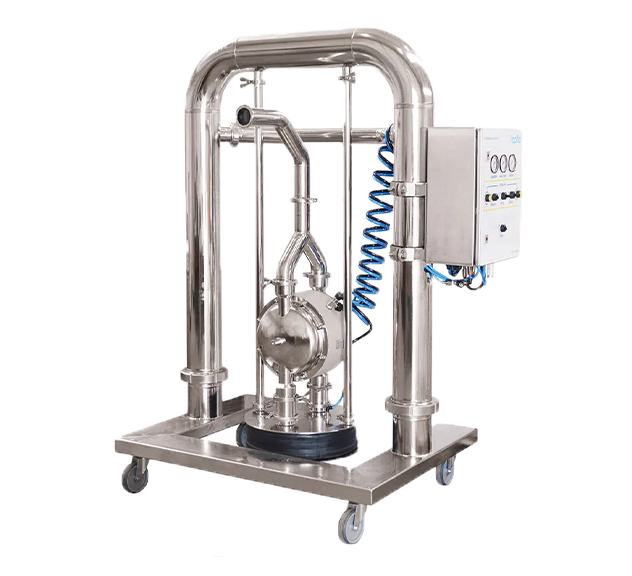

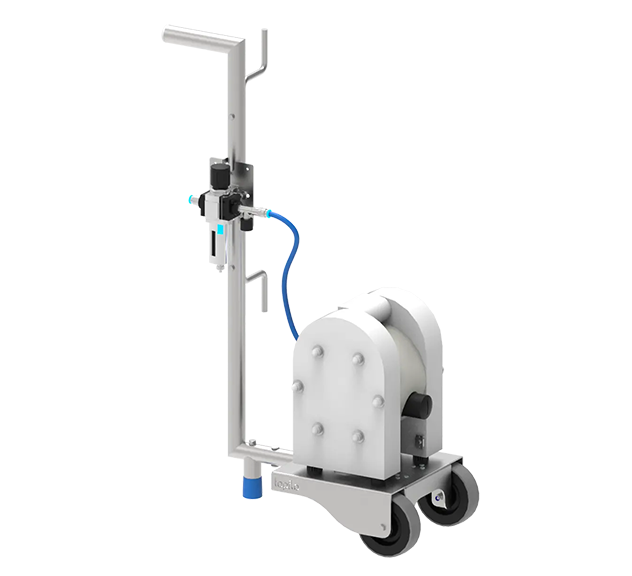

- Air Operated Diaphragm Pumps

- Submersible & Immersible Pumps (Borehole, Axial, Turbine, Single Stage & Multistage)

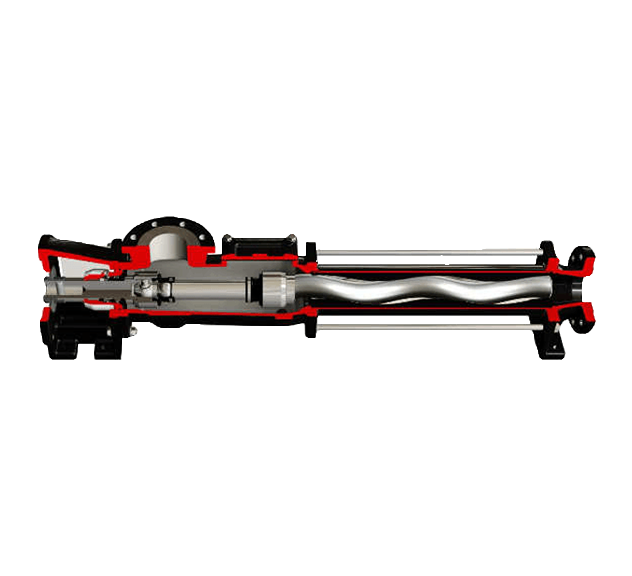

- Lobe & Progressing Cavity Pumps

- Piston Pumps

- Hand Pumps

- Booster Sets

- Internal, External & Helical Gear Pumps

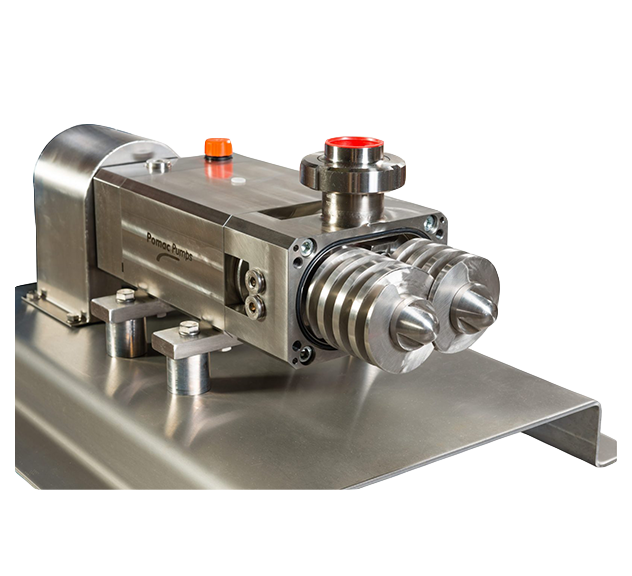

- Twin & Triple Screw Pumps

- Priming Systems (Air Ejector or Liquid Ring)

- Valves (Isolation, Flow Control, Pressure Relief & Reducing, Multi-Directional, Actuated)

- Strainers & Filters

- Flow Meters & Indicators

- Pneumatic & Electronic Level Indication & Batch Controller

- Control Panels & Inverters

- Ejectors

What type of applications can your Marine Pumps be used for?

Tapflo UK’s Marine Pumps can be used for the following applications:

- Air Conditioning & Cooling

- Fire Fighting

- Heeling

- Bilge

- Ballast

- Lubrication Oil Transfer & Supply

- General Service & Washing Circulation

- Refrigeration Supply & Circulation

- Black Water, Grey Water Sewage & Waste Water Transfer & Evacuation

- Potable Water Supply

- Pressure Boosting

- Refuelling & Offloading

What type of materials are your marine pumps made from?

Depending on the application and pump type we can offer our Marine Pumps from the following materials:

- PP-GF, HDPE, PVDF, PTFE

- Cast Iron

- Aluminium (AK-9 Marine Grade)

- Bronze

- Ni-Al Bronze

- Stainless Steel AISI 304 & 316(L)

- Duplex Stainless Steel & other exotic materials such as Titanium & Hastelloy-C

If being used on Sea Water, we would generally recommend using either our AK-9 Aluminium or HDPE (for Air-Operated Diaphragm Pumps) and Bronze or Ni-Al Bronze for centrifugal pumps as these offer the best corrosion resistance. Pumps in Cast & Sheet Stainless Steel AISI 316(L) as well as Cast Iron with sacrificial anodes are also available on request.

What drive types are available on your Marine Pumps?

Tapflo UK Ltd. is able to supply its Marine Pumps with the following drive possibilities:

- Electrically Driven (12V, 24V, 110V, 230V, 230-400V, 400-690V) – all motors are rated for continuous operation (S1 Duty Class) in both Single & 3 Phase as well as 50 & 60 Hz with a minimum ingress protection of IP54 all the way up to IP68. ATEX rated are also available on request.

- Air Driven – Discharge Pressures up to 8 Bar as standard however 16 Bar upon request with a 2:1 Pressure Booster

- Belt & Pulley Driven with Manual or Electro-Magnetic Clutches (12 & 24V)

- Hydraulically Driven

- Diesel & Petrol Driven

- Manually Operated

What Certification & Testing can you offer with your Marine Pumps?

Depending on the pump type, we can offer the following Certification & Testing:

- Bureau Vertias, Lloyds Register, SGS, DNV & Energy API Marine Type & Class Approved

- 1, 2.2 & 2.1 Material Certification

- Hydrostatic Pressure Testing

- Duty Point & Max Capacity Testing

- CE Declaration of Conformity

- ATEX Certification

- Non-Destructive Testing (Radiography & Dye Penetrant)