Our Progressive Cavity Pumps are volumetric pumps capable of self-priming and are suited to highly viscous, shear-sensitive & heterogeneous fluids containing gas, solids, abrasive particles & fibrous materials. Offering reversible flows, high discharge pressures up to 48 Bar & available in configurations from stages 1 to 8.

Industrial Progressive Cavity Pump

Hygienic Progressive Cavity Pump

Vertical Progressive Cavity Pump

Flanged Progressive Cavity Pump

Industrial Single Screw Dosing Pump

Hygienic Single Screw Dosing Pump

Hopper Pump

Double Shaft Hopper Pump

Biogas Hopper Pump

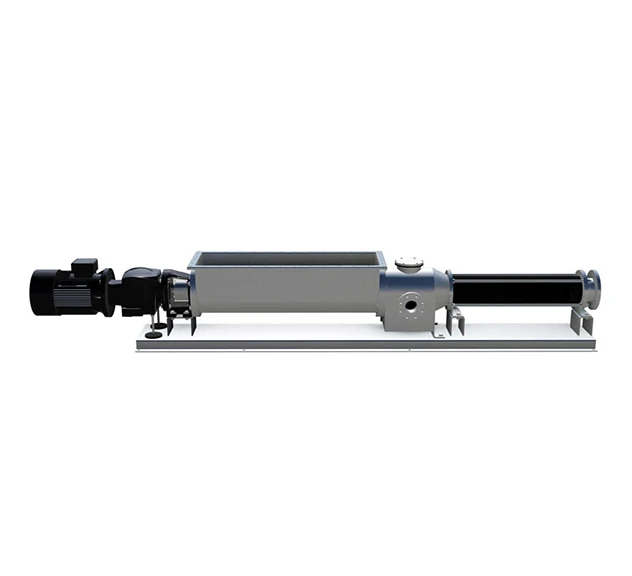

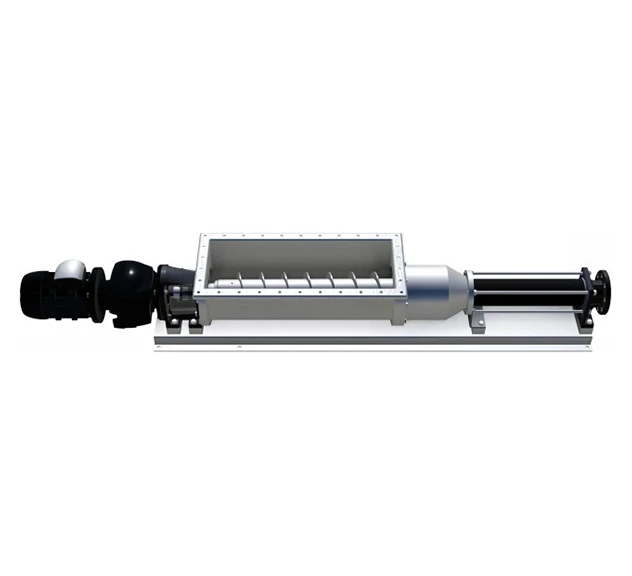

Auger Feed Screw Hopper Pump

Wobble Pump

Industrial Wobble Pump