At Tapflo UK, we offer an all-inclusive range of CIP (Clean in Place) equipment, including specialised Pumps, Mobile, Modular, and Multi-Tank CIP Systems, as well as ancillary components.

This guide explores the complexities of CIP, detailing not only the essential CIP Pumps (and versatile CIP-able Pumps) but also our advanced, full-scale CIP Systems, designed for optimal hygiene and efficiency across diverse industries.

What is CIP?

CIP is the abbreviation for Clean in Place, which refers to the method of cleaning vessels, equipment, and pipework that come into contact with the product being pumped, without the need for dismantling any of it. This process is automated and typically involves a sequence of steps that include pre-rinse, cleaning and final rinse, as well as the sterilisation of hygienic processes. These cycles can be carried out at temperatures of up to 85°C and often involve the use of acid and caustic detergents, alongside various sanitisers.

CIP Pumps can either be ‘Single-Use’, where the CIP fluid is disposed of after each cycle, or ‘Recovery’ based, where the fluid is recycled for re-use in subsequent cycles, features that offer greater efficiency and environmental benefits.

The Development of CIP: From Pumps to CIP Systems

Previously, the focus in the pump industry for CIP was primarily on the pumps themselves, the ‘workhorses’ that circulate cleaning fluids. While CIP Pumps remain crucial for businesses that require line cleaning without the need for a full system, or for specific applications where a process pump can double as a cleaning agent circulator, CIP requirements have since evolved.

At Tapflo UK, recognised as a systems expert in the process industry, we understand that effective CIP often requires a holistic approach. This led us to develop a comprehensive range of CIP Systems, while still catering to the continued need for individual CIP Pumps, as well as the versatility of “CIP-able” Pumps, which can perform dual duties.

Understanding CIP Pumps

A dedicated CIP Pump is designed to meet the highest standards of hygiene. These pumps are required to be hygienic, compliant with FDA regulations, and typically EHEDG certified, ensuring the CIP process is as hygienic as possible.

Hygienic Centrifugal Pumps are typically used as CIP Supply Pumps. Well-suited to handling fairly large volumes of water-like fluids at reasonable pressures (up to around 16 Bar), these pumps push the CIP fluid around the process, and often feed spray systems in process vessels with high volumes of CIP fluid at specific pressures (depending on the type of spray heads used, be it static spray balls, rotating spray heads, or cleaning machines).

Hygienic Self-Priming Centrifugal Pumps, as well as Hygienic Liquid Ring Pumps, serve as CIP Scavenge and/or Return Pumps. Their role is to evacuate the CIP fluid from the process vessel and pipework, either directing it to waste or returning it for recycling and re-use.

Tapflo UK's Range of CIP Pumps

CTH Hygienic Centrifugal Pump:

Our CTH Hygienic Centrifugal Pump offers exceptional sanitary performance for the Food, Beverage, and Pharmaceutical industries:

- Construction: Manufactured from AISI 316L Stainless Steel and electropolished to Ra < 0.8, these pumps provide superior mechanical strength and corrosion resistance

- Temperature Handling: With a long-coupled design, these pumps are capable of withstanding temperatures up to 180°C, ideal for demanding applications

- Design: End Suction, Close Coupled, Single Stage Hygienic Centrifugal Pumps with either an Open (6mm solids passage) or Semi-Open Impeller

- Applications: Food & Beverage, Dairy, Pharmaceutical, Cosmetics, Breweries & Wineries, and auxiliary applications, such as transfer of CIP liquids, detergents, and water

Key Features:

- FDA & EC1935 approved mechanical seals and elastomers

- Hygienic connections with DIN 11851 as standard (available with DIN 32676 clamp, ISO 2852 clamp, SMS thread, RJT thread on request)

- Maximum viscosity of 200 cSt

- Maximum particle diameter of 6mm (with a standard open impeller)

- ATEX available for use in hazardous zones

- Flow Rate of up to 74m³/hr

- Pressure up to 100m

- Modular design for easy maintenance and low downtime

- Available with drain plugs in various designs

CTS H Hygienic Self-Priming Centrifugal Pump (Scavenge Pump):

Designed for Sanitary and Food-Grade applications, our CTS H Hygienic Self-Priming Centrifugal Pump, also referred to as a Scavenge Pump, is ideally-suited to effective CIP scavenge and return duties.

- Construction: Constructed from AISI 316L Stainless Steel with surfaces electropolished to Ra <0.8

- Capabilities: Handles fluids with viscosities up to 200 cSt, with efficient solids-handling capabilities up to 6mm

- Suction Lift: Up to 4.5m, making them well-suited to applications where suction lift is required, or for pumping highly aerated fluids

- Applications: Food & Beverage, Dairy, Pharmaceutical, Cosmetics, Breweries, Wineries, as well as the transfer of CIP liquids

Key Features:

- Self-priming

- FDA & EC1935 approved mechanical seals and elastomers

- Hygienic connections (DIN 11851 as standard)

- ATEX available for use in hazardous zones

- Flow Rate up to 58m³/hr

- Pressure up to 40m

- Optional lubricated and externally quenched mechanical seals for dry running potential, or for solidifying products

Introducing CIP-able Pumps

While not exclusively designed as CIP pumps, ‘CIP-able’ pumps are those typically used for product transfer while also being capable of handling CIP fluids. This versatility simplifies processes and negates the need for additional pumps in certain applications.

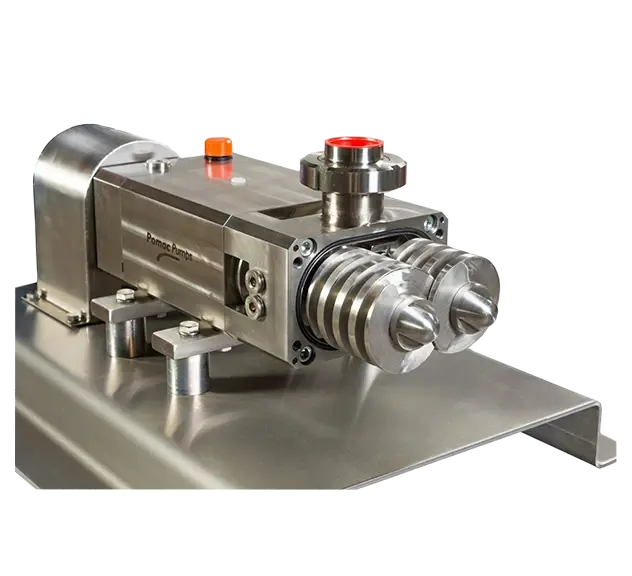

A prime example of this is our Hygienic Twin Screw Pump. Most hygienic pumps in contact with the product are typically Positive Displacement Pumps that are not naturally suited to pumping water, or at the high capacities often required for a CIP process. However, our PDSP Hygienic Twin Screw Pumps are uniquely capable of pumping the product and the CIP fluid in both supply and scavenge applications. This dual functionality greatly simplifies the process line by reducing the number of pumps required, limiting spares holding and maintenance times.

Tapflo CIP-able Pumps in Action

Tapflo Pumps UK were contacted for the supply of a hygienic pump for use on both liquid stock and CIP. The customer’s goal was to simplify their CIP pipework and limit the number of pumps on-site, thereby reducing spares holding and maintenance. Our PDSP Hygienic Twin Screw Pump proved to be the ideal solution.

Application Details:

- Fluid: Liquid Stock

- Temperature: 70−110∘C

- Viscosity: 1-2000 cPs

- Specific Gravity: 1.1 kg/dm3

- Required Capacity: 30 m³/hr @ 2 Bar (Liquid Stock) & 50 m³/hr @ 2 Bar (CIP)

- Suction Conditions: 200 mBar vacuum on evaporator tank (Liquid Stock Duty)

- Required Connection Type: DN100/80 Tri-Clamp

- Pipework Size: Sized to suit the pump

- Motor Supply: 230-400V or 400-690V/3 Ph/50 Hz

Pump Supplied:

- Model: PDSP 3-60

- Description: Long Coupled, Hygienic Self-Priming Screw Pump (Double Screw)

- Rated Capacity: 30 m³/hr @ 2 Bar (40 Hz) & 50 m³/hr @ 2 Bar (70 Hz)

- DN100/DN80 Tri-Clamp Counter Connections w/ Weldable Counter Parts

- SS 316L Wetted Components, 0.8 Ra Surface Finish with Hardened Screws

- SS 304 Gearbox

- Single Mechanical Seal, SiC/SiC/EPDM Elastomers (FDA Approved)

- Motor 15 kW/4 Pole/400-690V/3 Ph/50-60 Hz/IP55/Class F/IE3 Premium Efficiency Class

The PDSP 3-60 was delivered within 6 working weeks, and the customer was extremely satisfied with its performance on both process and CIP pumping duties, demonstrating the significant advantages of a truly CIP-able pump.

How to Quantify my CIP Flow Rate Requirement?

The flow requirement for CIP is determined by the minimum velocity required through the pipework in place, typically 1.5 m/s minimum. As such, your CIP flow requirements can be quantified as follows:

| Process Pipe ø, mm | CIP Supply Return Pipe ø, mm | Minimum CIP Flow, m³/hr |

| 25 | 25 | 2.1 |

| 38 | 38 | 5.2 |

| 50 | 50 | 10 |

| 65 | 65 | 16 |

| 75 | 65 | 24 |

| 100 | 75 | 42 |

| 125 | 100 | 70 |

| 150 | 125 | 100 |

| 200 | 150 | 170 |

| 250 | 200 | 280 |

| 300 | 200 | 400 |

| 350 | 250 | 520 |

| 400 | 250 | 700 |

CIP Systems

While pumps are the pillars of fluid transfer in any process, when it comes to CIP, their efficiency and compatibility are deeply tied to the design and capability of the surrounding CIP system. At Tapflo UK, we design and manufacture CIP Systems that are used in applications requiring frequent cleaning, flexibility, and integration into existing processes. Suited for evolving production needs, these systems support efficient sanitation, recovery, and reuse of cleaning agents, and are optimised for hygiene, cost savings, and sustainability, especially in large-scale or multi-stream operations.

Key System Design Elements That Impact Pump Requirements:

- Flow Rate & Pressure: Pumps must maintain turbulent flow (typically ≥1.5 m/s) for residue removal. This guides pump sizing and material selection

- Chemical Compatibility: CIP cycles involve the use of caustic and acidic solutions; pumps must be able to withstand aggressive cleaning agents

- Temperature Resistance: Cleaning stages often exceed 70°C; pump components must maintain integrity under thermal stress

- System Integration: Pumps should support automated control, validation (such as conductivity monitoring), and variable CIP cycle profiles

Tapflo UK’s CIP System Recommendations

Mobile CIP System:

Our Mobile CIP System is a compact and versatile cleaning solution tailored for smaller operations or facilities requiring flexibility. With skid-mounted and wheel-mounted options available, it offers portability and efficiency without the commitment of a centralised system.

- Tank Configuration: 350L

- Mobility: Compact unit with skid or caster wheel mounting

- Temperature Range: 20 – 90°C

- Automation: Basic PLC controls with monitoring capabilities

- Material: Food-grade Stainless Steel (304/316)

Modular CIP System:

Our Modular Clean-In-Place (CIP) System is a pre-assembled, scalable cleaning system tailored for industries with diverse and evolving cleaning requirements. Designed for seamless integration into existing facilities, this system minimises installation time and operational disruption, delivering consistent, high-quality cleaning performance while reducing utility consumption and maximising operational uptime.

- Components: Tanks, Centrifugal Pumps, heat exchangers, flow meters, conductivity sensors & temperature sensors

- Cycle Types: Supports alkali, acid, rinse & air purge cycles with customisable time, flow & concentration settings

- Capacity: Scalable for small to large facilities, with tank sizes & pump capacities tailored to customer requirements

- Automation: Features a user-friendly PLC interface for programming & monitoring cleaning cycles

- Temperature Range: Operates effectively up to 90°C for caustic cleaning

- Material: Constructed using FDA-compliant Stainless Steel (304/316), ensuring durability & sanitation

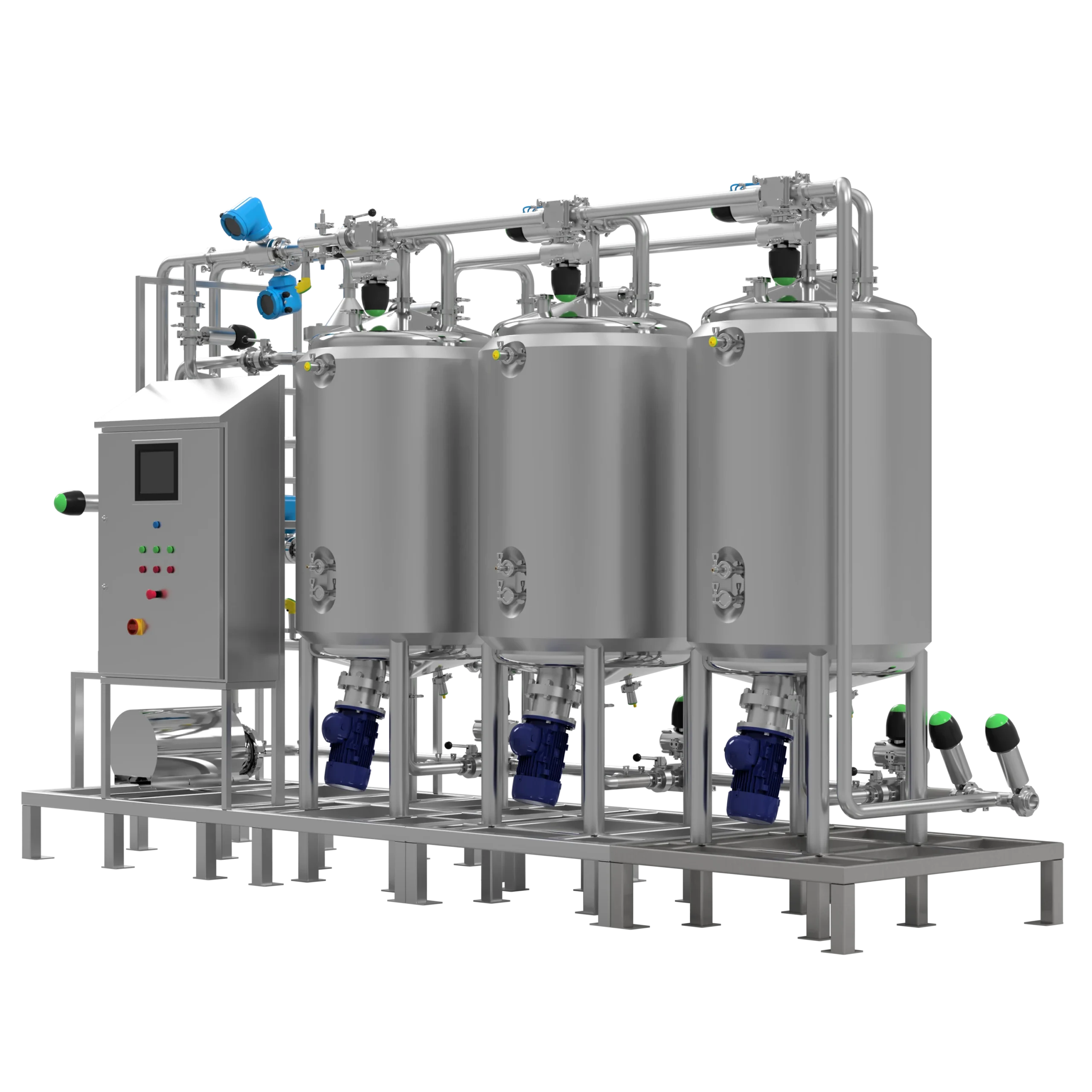

Multi-Tank CIP System:

Our Multi-Tank Clean in Place (CIP) System offers an advanced, high-capacity cleaning solution designed for operations requiring frequent sanitation, efficiency, and sustainability. Designed to enable recovery and reuse of cleaning agents, these systems are ideal for large-scale or multi-stream processes where hygiene, cost-efficiency, and resource optimisation are critical. Configurable as 2, 3, 4 (or more!) tank systems, they provide unmatched flexibility for custom setups.

- Tank Configuration: 2-4 tank systems for rinse, detergent, and recovery processes

- Flow Rate: Customisable up to 24m³/hr

- Temperature Range: Up to 90°C for alkali cleaning

- Cleaning Velocity: Turbulent flow achieved at 1.5 m/s or higher

- Material: Food-grade Stainless Steel (304/316)

The world of CIP is dynamic, encompassing everything from individual pumps to sophisticated, integrated systems. At Tapflo UK, our industry expertise allows us to offer a comprehensive suite of solutions, whether you require a dedicated CIP Pump, a versatile CIP-able Pump for dual duties, or a complete, custom-designed CIP System.

By understanding the nuances of each option and tailoring them to your specific industry needs, we help businesses achieve consistent product quality, enhance operational efficiency, and comply with stringent safety and hygiene standards, ensuring sustainable growth and the highest levels of safety.