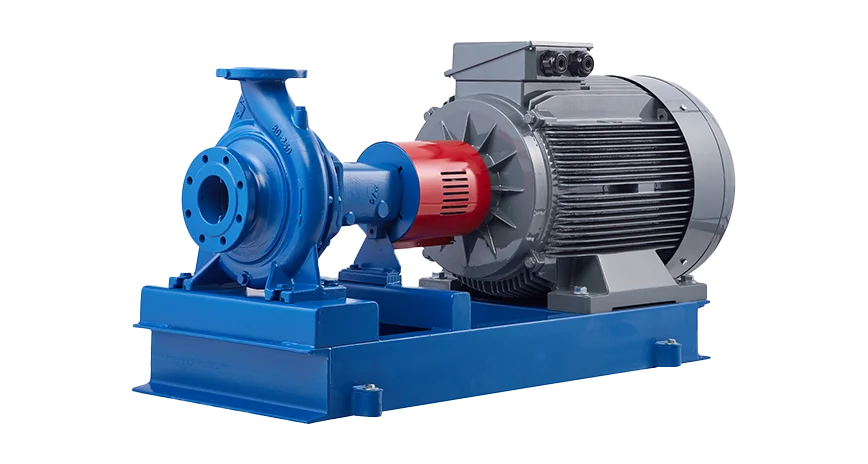

Our CTH Hygienic Centrifugal Pump range delivers exceptional sanitary performance for the Food, Beverage and Pharmaceutical industries. Manufactured from AISI 316L Stainless Steel and electropolished to Ra<0.8, these pumps offer superior mechanical strength. Able to withstand temperatures up to 180°C, the CTH Hygienic Centrifugal Pump is durable and offers superior corrosion resistance, making it the ideal pump for demanding applications.

Typical industries/applications for our Hygienic Centrifugal Pump:

Overview

Features & Benefits

Specifications

Variations

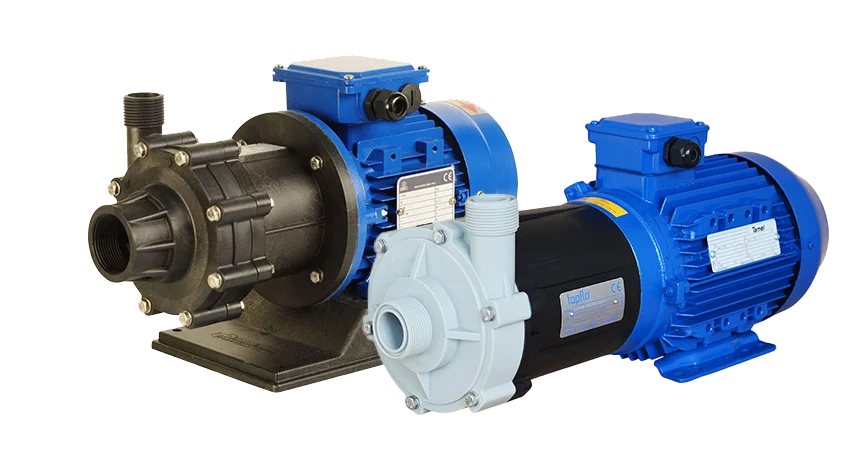

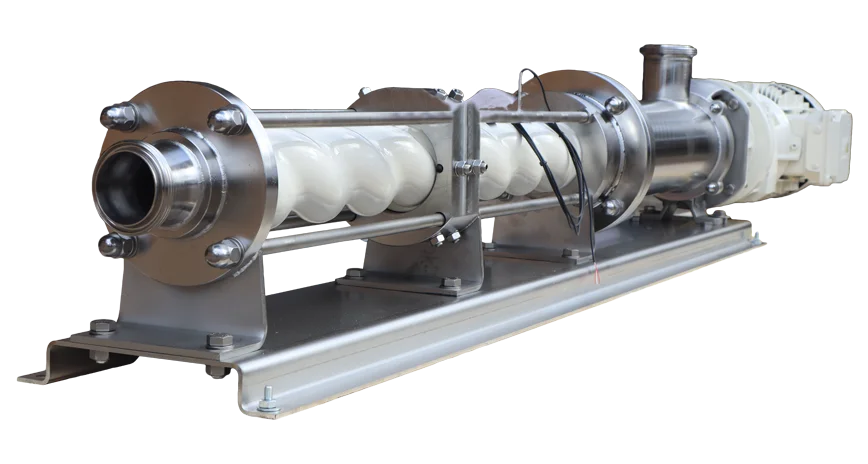

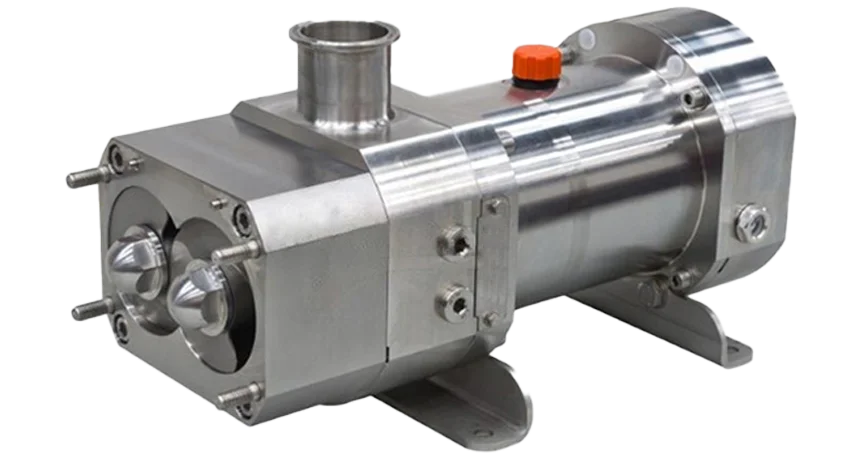

Tapflo’s CTH Hygienic Centrifugal Pump range is suitable for various applications within the Food, Beverage and Pharmaceutical industries at competitive pricing and quick lead times. The Hygienic End Suction, Close Coupled, Single Stage Centrifugal Pumps feature either an Open (6 mm Solids Passage) or Semi-Open Impeller and are manufactured from Stainless steel AISI 316L, electro polished to Ra <0.8, to offer high mechanical and corrosion resistance for a plethora of hygienic applications at competitive pricing.

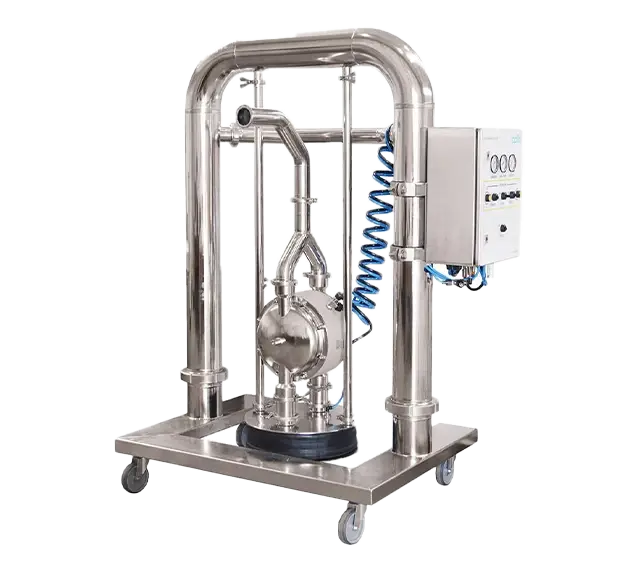

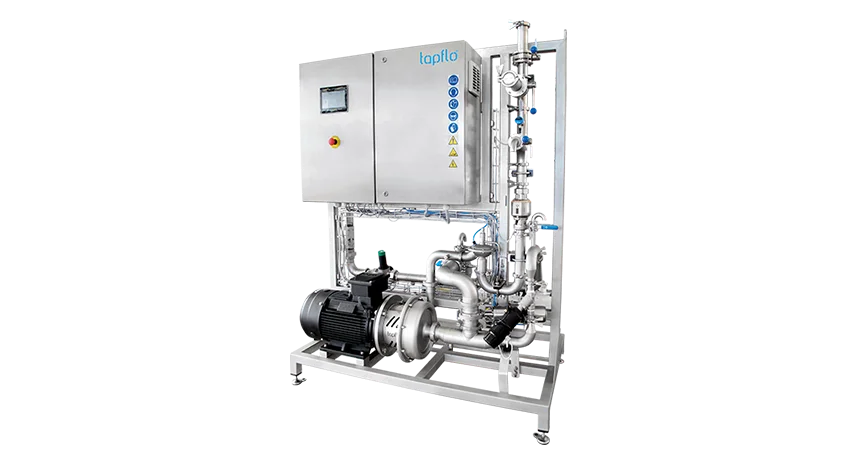

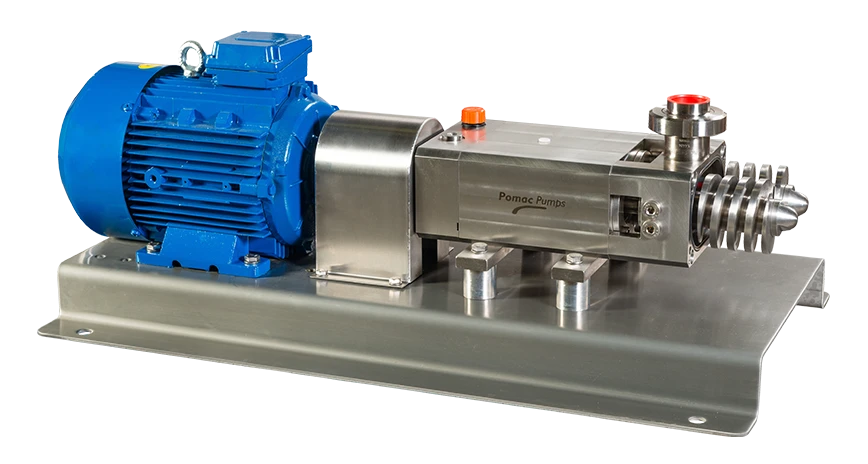

Long-Coupled Hygienic Centrifugal Pump

The CTH Pump is available with a long-coupled design. Typically the close-coupled design can handle fluids up to 90°C but with the long-coupled design, liquids with a higher temperature, up to 180°C can be pumped. We also recommend this design when handling highly flammable fluids or when the pump will be installed in a harsh ATEX zone. Installing a long-coupled design protects the motor if the mechanical seal fails, there is the possibility that if you were handling flammable liquids with a close-coupled pump, a leak could cause a spark and be extremely hazardous.

- Pump casing & wetted parts electropolished to Ra<0.8

- FDA & EC1935 approved mechanical seals and elastomers

- Hygienic connections with DIN 11851 as standard

- Viscosity: Max 200 cSt

- Particles: max diameter of 6mm (with standard open impeller)

- ATEX rating, ideal for hazardous zones

- Auxiliary applications such as transfer of CIP liquids, detergents and water

The CTH Pump has been innovatively designed with only 19 components, enabling it to be maintained and troubleshot in a limited time frame. This results in very short downtimes and extremely low maintenance costs. In fact, in many cases, once installed, these pumps are maintenance-free! The modular design enables the pumps to be supplied with various build options, making it an incredibly robust and versatile pump suitable for a wide range of applications and installations.

Furthermore, with casing and impeller in <0.8 Ra electro-polished stainless steel AISI 316L, and possibilities for draining & also fitted with hygienic shroud & jacketing options means it meets the demands of cleanability and quality of high finish required within Food, Beverage and Pharmaceutical industries.

The CTH Pump is also available with a drain plug in various designs, including facing vertically down, vertically at an angle, facing sideways and horizontally facing forward. Speak to a member of the team to discuss including a drain plug on your final design.

| Mechanical Seal |

Single ceramic/graphite (standard), SiC/SiC or SiC/graphite, Optional with Lubrication or Flushing |

| O-Rings |

EPDM FDA approved (standard), or FEP/silicone FDA approved |

| Motor |

IP55; IEC frame B34; Available with ATEX cat 2 or 3; Eex e or Eex d, IE3 |

| Pressure Rating |

100m (PN10) |

| Temperature |

Max 90°C; 180°C for long coupled pump |

| Viscosity |

Max ~200 cSt |

| Particles |

Max diameter is 6 mm (std open impeller); bigger if soft particles |

| Drive Type |

Electric |

| Flow Rate |

up to 74 m³/hr |

| Pressure |

up to 100m |

| Material |

Stainless Steel AISI 316L |

| Self-Priming |

No |

| Solids Handling |

6mm |

| Viscosity |

0-200 cSt |

| Connection points |

DIN 11851 thread (standard)

DIN 32676 clamp

ISO 2852 clamp

SMS thread

RJT thread |

Hygienic Shroud: polished in AISI 304L, protects the motor from spraying water during the pump cleaning procedure.

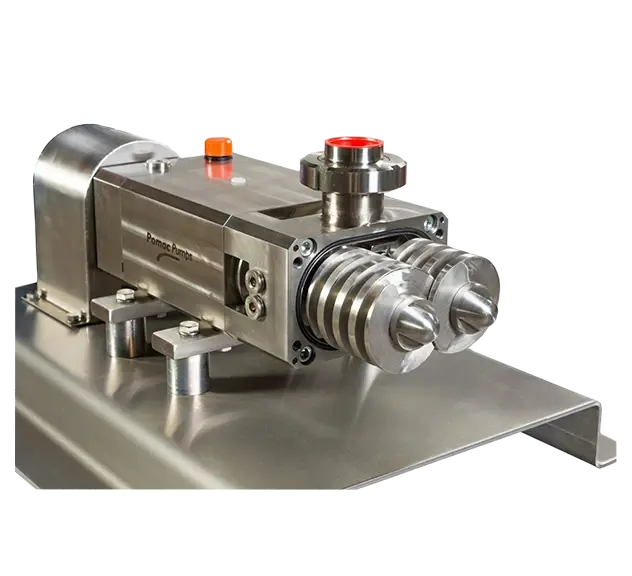

Buffer Fluid System: an oil resevoir is connected to the mechanical seal chamber for applications that may solidify or crystalise.

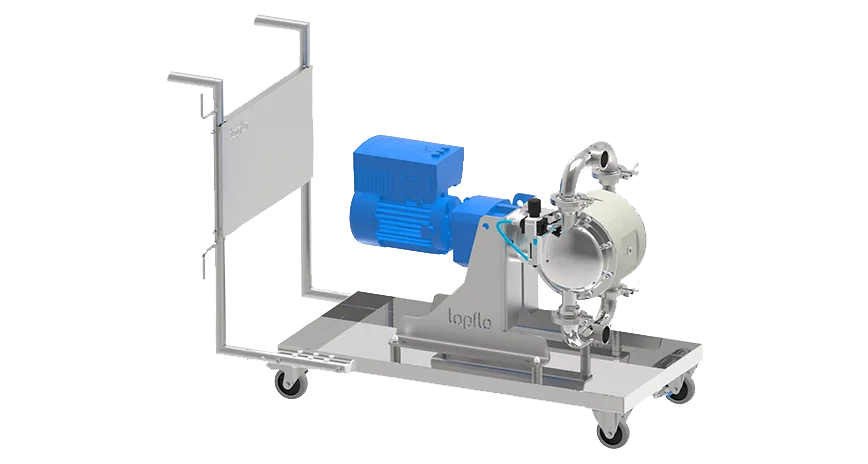

Long Coupled: for pumping hot liquids, complete on a baseplace with coupling and cover.

Casing Drainage: draining plug with a variety of connection types allowing the pump to be emptied.

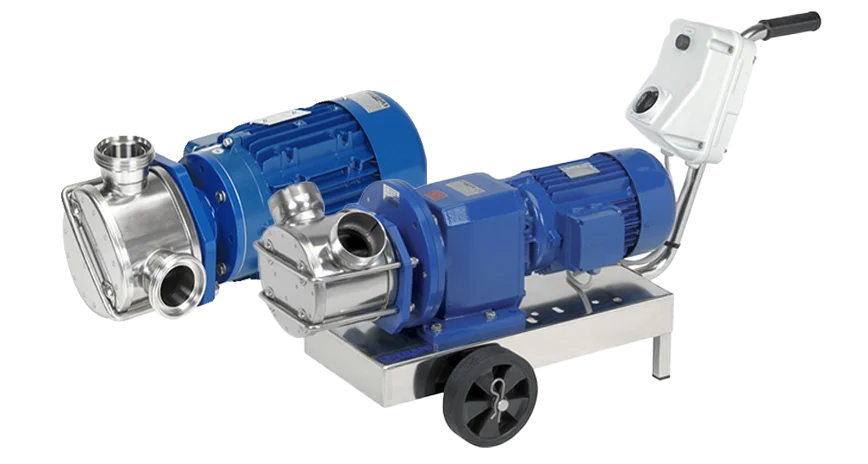

Adjustable feet: allows for easy cleaning underneath the pump and easy transport if the pump needs to be moved.

Heating Jacket:

To use a Tapflo Hygienic Centrifugal Pump with a Heating Jacket, a few extra parts are required, listed below.

- 1 x Pump Back Cover for Heating Jacket (111)

- 1 x Pump Back Casing with Heating Jacket (120)

- 2 x Joint for Pump with Heating Jacket (125)

The jacket is welded into the pump back casing and a heating or cooling medium is continuously circulated in the jacket. Heating Jackets can be fitted in order to provide greater protection for the mechanical seal in cases where there is a risk of solidification of the product being pumped.

They can also be used when the temperature of the pumped product has to be maintained to a specific temperature, high or low. The jacket has two ISO G ½” connections, other options are available upon request, such as flanged. Connection to the jacket is done by using flexible hoses to prevent any undue stress and strain on the heating jacket connectors. The medium used needs to be fully compatible with the materials of the pump.

Electro-Polished, Stainless Steel AISI 316

Electro-Polished, Stainless Steel AISI 316L, Hygienic Shrouds can easily be fitted to provide added protection for the motor during wash-downs as well as an easier cleaning surface with increased resistance to bacterial build-up.

Additional Parts Required

1 x Hygienic Pump Shroud (31) 4 x Shroud Feet (34) 4 x Shroud Feet Screws (341) 4 x Shroud feet Screw Washers