| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| GR Series | 43.8 | 24 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| GR Series | 43.8 | 24 |

How does a V-Belt Drive Flexible Impeller Pump work?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

How does this differ from other products on the Tapflo website?

What applications are suited to this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with highest-quality Flexible Impeller Pumps.

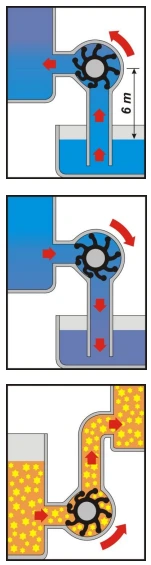

The GR Series V-Belt Drive Flexible Impeller Pump is a self-priming pump designed to handle viscous fluids up to 50,000 cPs. With the ability to self-prime up to 6m from dry, this pump provides superior suction lift capabilities.

This model features a unique belt-driven design that separates the motor from the pump head, preventing overload when handling viscous or solids-laden fluids. Additionally, this pump can be installed on either a baseplate or trolley-mounted and can be supplied with or without a control panel.

Typical applications for our V-Belt Flexible Impeller Pump:

Download Brochure

This V-Belt Flexible Impeller Pump is a type of positive displacement pump designed for gentle fluid transfer and excels in handling viscous liquids and liquids containing solids. They work by trapping fluid between the internal impellers and pushing it from the suction port to the discharge port.

This GR V-Belt Self-Priming Flexible Impeller Pump is characterised by its belt-driven design, where the motor is separated from the pump head and driven by a belt drive. When being used on particularly vicious or solids-laden fluids, the belt will slip to protect the motor from overloading.

The series can be paired with either a baseplate or trolley, and with or without a control panel. The control panel features an on/off/reversing switch, which is fitted to the terminal box of the motor when a control panel isn’t supplied. Dry Run Protection can also be fitted to the pump head, and Manual or Spring-Loaded By-Passes for demanding applications.

This V-Belt Flexible Impeller Pump is a type of positive displacement pump designed for gentle fluid transfer and excels in handling viscous liquids and liquids containing solids. They work by trapping fluid between the internal impellers and pushing it from the suction port to the discharge port.

This GR V-Belt Self-Priming Flexible Impeller Pump is characterised by its belt-driven design, where the motor is separated from the pump head and driven by a belt drive. When being used on particularly vicious or solids-laden fluids, the belt will slip to protect the motor from overloading.

The series can be paired with either a baseplate or trolley, and with or without a control panel. The control panel features an on/off/reversing switch, which is fitted to the terminal box of the motor when a control panel isn’t supplied. Dry Run Protection can also be fitted to the pump head, and Manual or Spring-Loaded By-Passes for demanding applications.

The V-Belt Drive Flexible Impeller Pump offers many benefits for the end user, some of which include:

| Max Flow (m³/hr) | 43.8m³/hr |

| Max Pressure (m) | 24m |

| Max Temperature (°C) | 100°C |

| Max Viscosities (cPs) | Up to 50,000 cPs |

| Self-Priming | Up to 6m from dry |

Voltages: 110, 230 & 400V (1 & 3 Phase)

Speeds: 300, 470, 600 & 700 rpm single & dual speed (235-470, 300-600 & 350-700 rpm)

Counter Connections: All pumps are supplied with Garolla Fittings as standard however a wide range of connection & counter connection types are available upon request.