The Importance of Centrifugal Pump Safety

Centrifugal Pumps are commonly used to handle corrosive and hazardous substances, making safety measures critical to protect personnel, equipment and the environment. Correct training, maintenance and monitoring of Centrifugal Pumps are essential in preventing accidents, injuries or environmental damage.

Safety protocols also ensure process integrity, thus reducing the risk of costly downtime. Compliance with regulations and standards is non-negotiable, as non-compliance can result in legal consequences and reputational damage. In hygienic applications like the Food and Pharmaceutical industries, safety is vital to maintain product quality and prevent contamination, safeguarding public health and brand reputation.

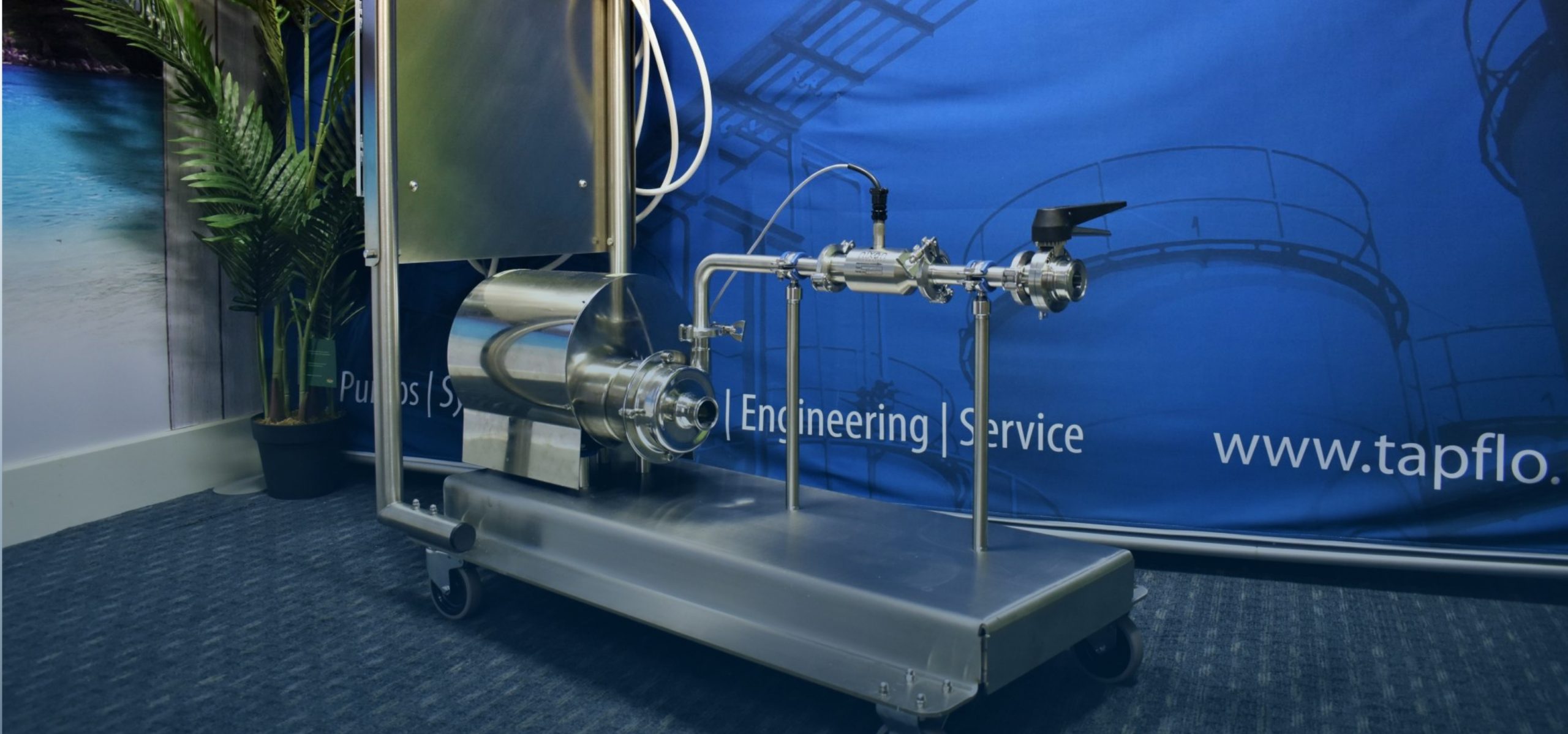

Understanding Centrifugal Pumps & Their Applications

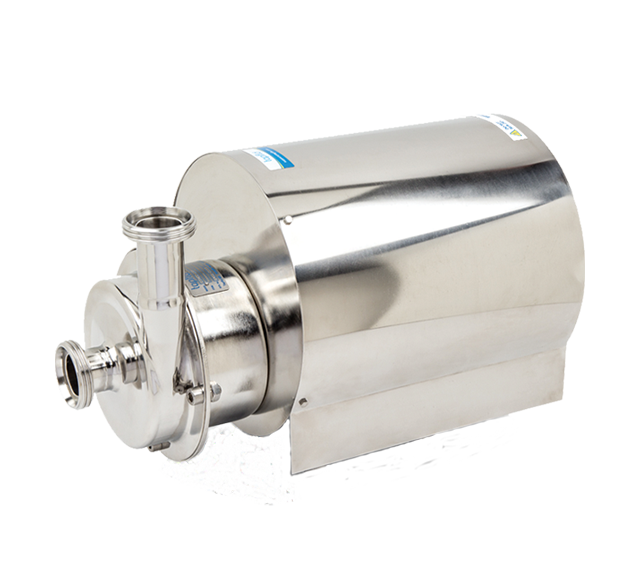

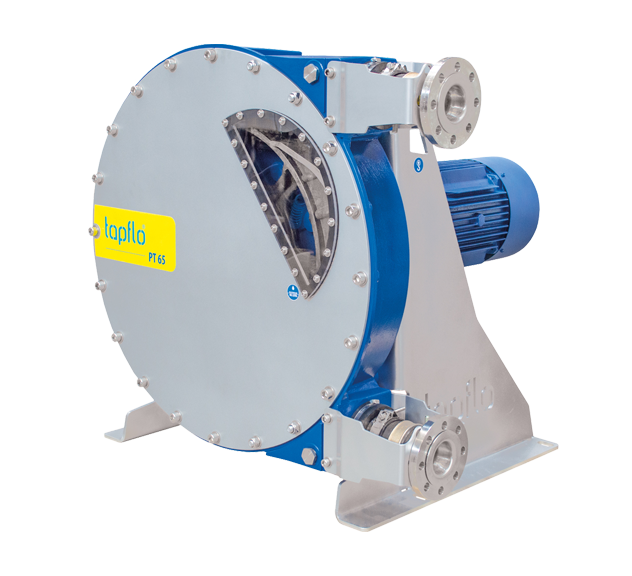

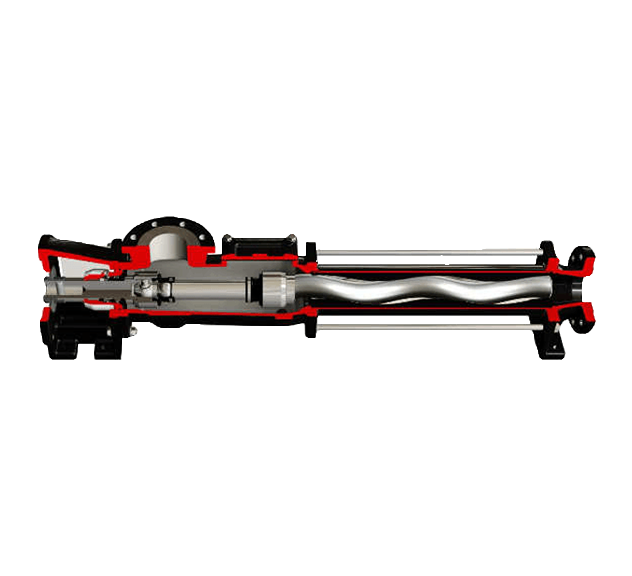

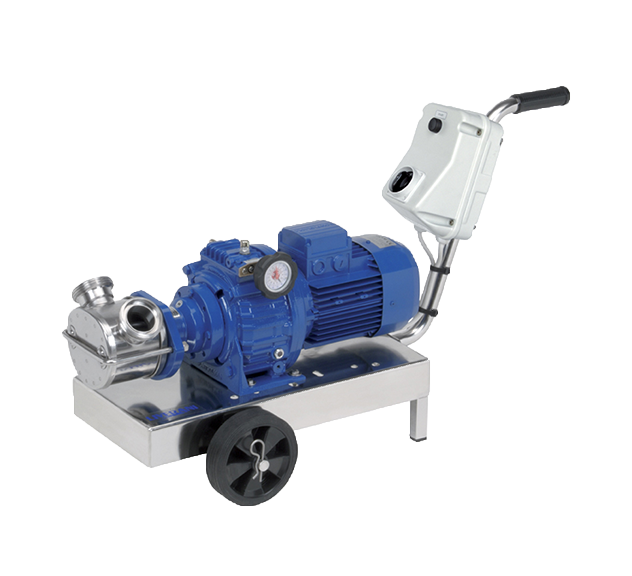

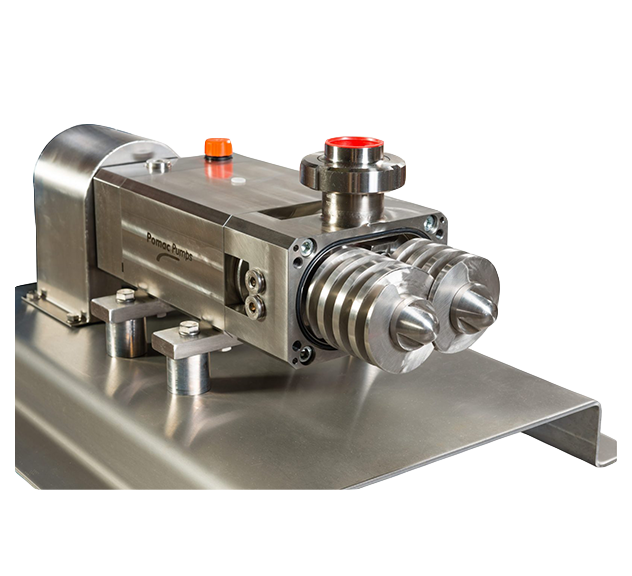

Centrifugal Pumps are mechanical devices used to transport fluids, typically liquids, from one place to another. These pumps operate by using a rotating impeller to create centrifugal force. This draws fluid into the pump, increases its pressure and propels it out of the pump through the outlet. This mechanism allows for the efficient transfer of liquids in various applications.

Centrifugal Pumps are widely used in the Industrial and Hygienic industries, catering to Food & Beverage, Pharmaceutical, Water & Wastewater Treatment as well as Paint and Paper applications, and are renowned for their efficient fluid-handling capabilities.

Ensuring correct safety measures are in place and adhered to is essential when working with and operating Centrifugal Pumps. Here are a few of the reasons why these safety measures are necessary:

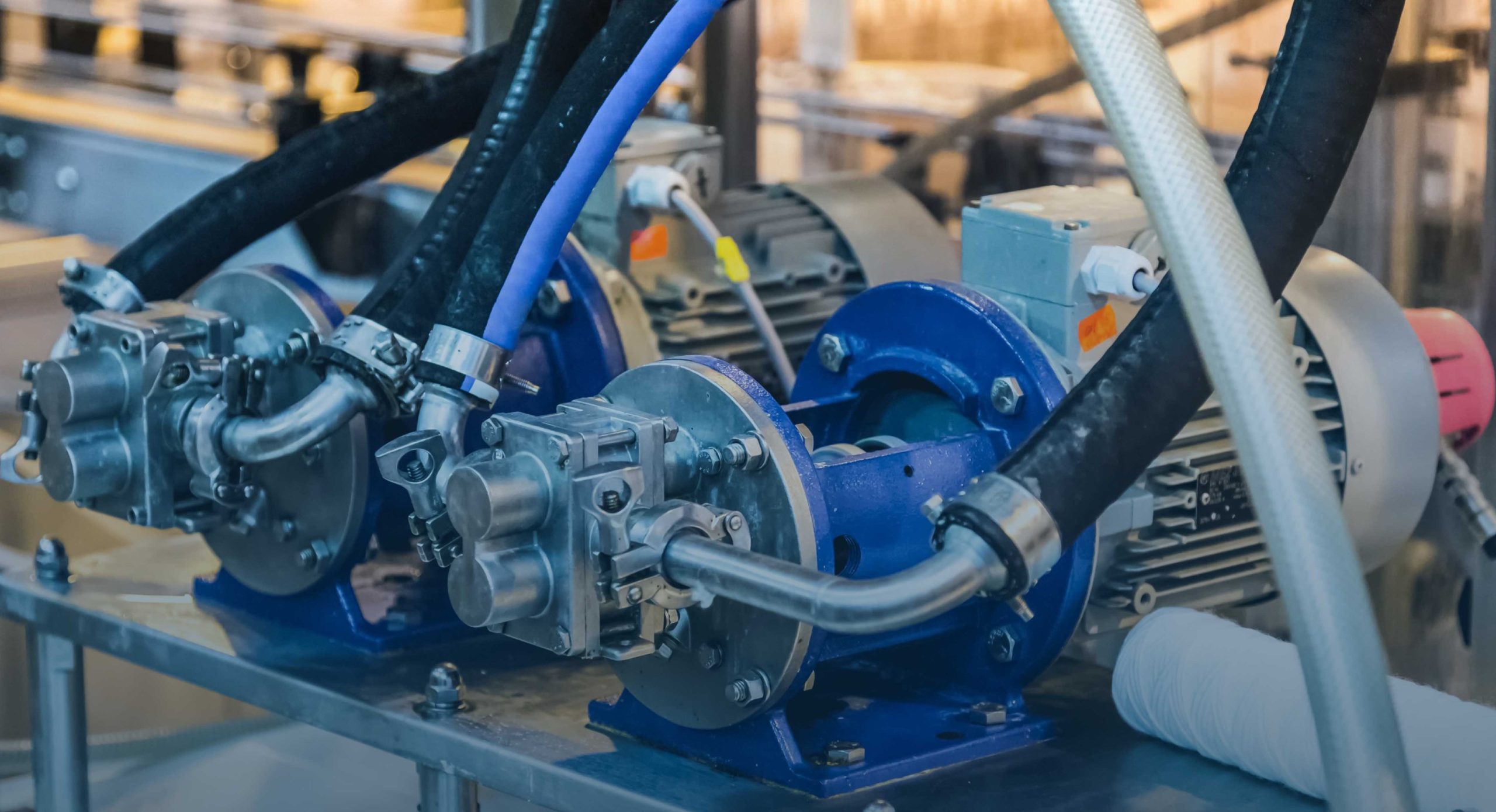

- High-rotational speeds: their high-rotational speeds can generate significant kinetic energy. This poses a serious risk to personnel and equipment if not handled properly

- Moving parts: with their many moving parts such as impellers and shafts, operators and maintenance staff could be at risk of injury if not handled correctly

- Fluid handling: as these pumps move various fluids including corrosive, toxic or flammable substances, mishandling these liquids could result in leaks which in turn could lead to chemical exposure, fire or even explosions

- Pressure buildup: Centrifugal Pumps can generate high pressure in the fluid system they’re connected to. If not properly designed or maintained, there’s risk of pressure-related incidents, including pipe bursts or equipment failure

- Electrical hazards: electric motors power most Centrifugal Pumps and so improper connections or malfunctions could result in electrical shocks or fires

To mitigate these risks, safety measures such as training for operators, the use of Personal Protective Equipment (PPE), regular inspection and maintenance, proper installation and adherence to safety protocols and guidelines are vital.

Additionally, safety devices and alarms can be installed to control and monitor pump operation. This will help to prevent accidents and protect both personnel and equipment.

Centrifugal Pump Safety Tips

1. Equipment Inspection & Maintenance:

Regular inspection and maintenance of your pumps are crucial for safe and efficient operation. Execute a scheduled inspection program to assess components such as impellers, shafts, seals and bearings for damage and wear. Ensure moving parts are correctly lubricated, pump components are aligned and electrical connections, wiring and motor controls are inspected. We recommend keeping a detailed record of inspections, maintenance and repairs. You also have the option to install pressure relief valves or systems to prevent over-pressurisation of the pump and system.

2. Proper Installation & Alignment:

Prior to installation of your Centrifugal Pump, carry out a site assessment to ensure a suitable location is identified. Factors like foundation stability, access for maintenance and proximity to power sources should all be considered. Prepare a level and stable foundation to support the pumps weight and vibrations. During installation, align the pump and motor using alignment tools. You should also pay close attention to torque specifications when tightening bolts and fasteners to prevent loose connections and leaks. If the pump is coupled to a motor, install the coupling correctly and ensure that coupling guards are in place to prevent accidental contact with moving parts.

3. Personnel Training & Certification:

Training should cover pump operation, maintenance, safety protocols and emergency procedures. Certified operators are better equipped to handle pump-related challenges, identify potential issues and respond to emergencies effectively. Proper training enhances overall safety, minimises the risk of accidents and promotes efficient pump operation.

4. Safe Start-Up & Shutdown Procedures:

Establish clear and documented protocols for the safe start-up and shutdown of Centrifugal Pumps. Before starting, ensure that all system components are in proper working order, valves are correctly positioned and personnel are aware of their roles and responsibilities. During shutdown, follow a systematic process to depressurise and secure the system. Proper start-up and shutdown procedures minimise the risk of accidents, protect equipment and contribute to the efficient pump operation while promoting safety in the workplace.

5. Monitoring & Controlling Pump Parameters:

Continuously monitor and control critical pump parameters such as flow rates, pressure levels, temperature and motor conditions. Use appropriate tools and automation systems to ensure that the pump operates within safe operating limits. Install alarms and shutdown mechanisms to respond quickly to deviations. Regularly calibrate and maintain monitoring equipment for accuracy.

6. Handling Hazardous Materials Safely:

It’s critical to prioritise safety when dealing with Centrifugal Pumps that transport hazardous materials. Ensure operators are properly trained to handle these materials. This includes accurate storage, transfer and disposal procedures. To prevent leaks or spills, use suitable PPE and containment measures. Maintain emergency response plans and equipment, such as spill kits and eyewash stations, for swift action in case of accidents. It’s always recommended that operators follow industry standards and regulatory guidelines when it comes to dealing with these substances.

7. Emergency Response & Shutdown Procedures:

Create clear emergency and shutdown plans. Designate trained operators to handle incidents like leaks, equipment malfunctions and fires quickly and safely. Establish swift shutdown procedures to isolate the pump during emergencies, with easily accessible emergency shut-off controls. Regularly review and practice emergency response plans with your team to maintain readiness. Remember, well-executed procedures help minimise damage, protect personnel and prevent further escalation during critical incidents involving Centrifugal Pumps.

8. Replace Old Parts:

Often, worn-out components of Centrifugal Pumps lead to workplace accidents and can even damage the pump itself. Even small parts, such as a bearing or casing wear ring, can cause catastrophic safety issues if they’re worn out. If the pump shaft starts to wobble, it can lead to the pump overheating. To avoid this, check the safety suction lines and pipe plugs frequently. Eventually, sealants wear away and can allow foreign objects into the pump itself. Always replace worn-out parts and components as often as possible.

9. Use a Centrifugal Pump for Intended Use:

There are different types of Centrifugal Pumps, and some are only intended to transport a certain type of material. Operators should never run liquid through a pump not designed to handle it. For example, pumping corrosive or flammable liquids through a pump intended for water or waste can lead to complications. The environment should also be clear of dangerous materials, especially if it’s flammable. Using a pump properly will maintain the levels of cleanliness, pressure, temperature and flow levels needed to keep operations safe.

10. Appropriate System Accessories:

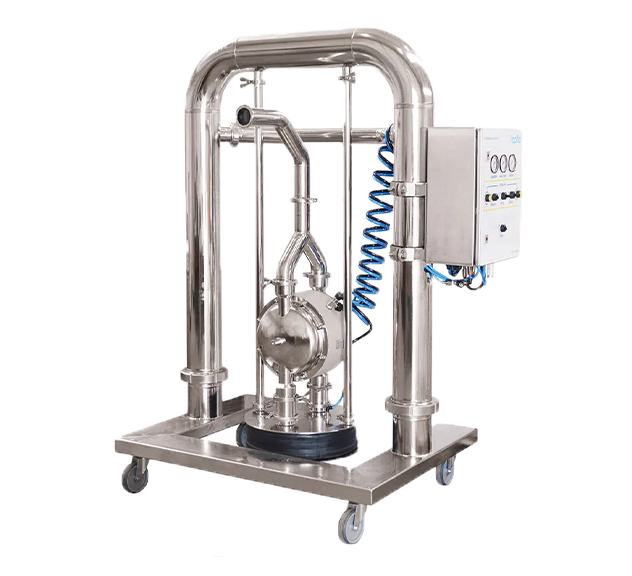

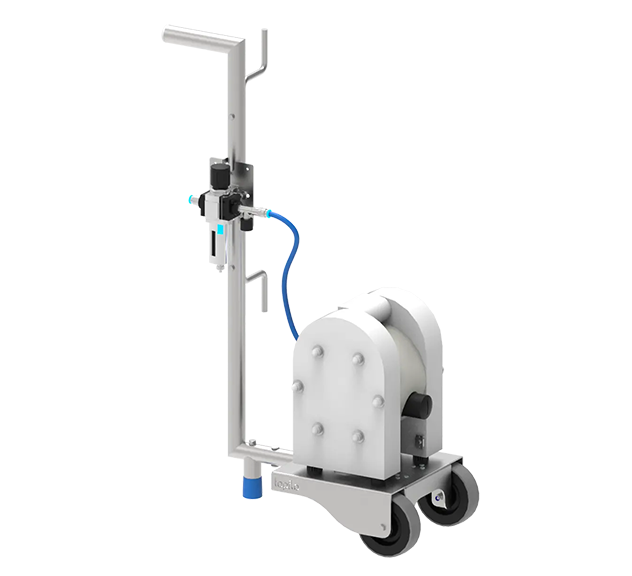

Numerous system accessories can be supplied with the pump to extend its usage. Accessories often have alarms that shut off the system during safety emergencies. Examples of such system accessories include:

- Diaphragm Barrier Alarm System: this system will immediately sound an alarm and shut off the pump in the event of a diaphragm break

- Dry-Run Prevention System: this system will immediately sound an alarm and shut off the pump should it run dry

- Level Control System: this system is operated with pneumatic components only. The level control system may be installed in sumps, tanks or tubs to start and stop the pump at certain liquid levels

Why Regular Audits & Inspections are Important

Periodic audits and inspections play a vital role in maintaining the ongoing safe operation of Centrifugal Pumps. These activities help to identify potential issues, assess the condition of equipment and ensure compliance with safety protocols.

Additionally, by establishing a regular schedule for audits and inspections (ideally annually), you ultimately reduce the risk of accidents and unexpected failures.

Here’s what to keep an eye on during your inspection:

- Physical condition of the pump, looking for signs of corrosion, leaks or damage to components

- Verify that the pump and motor are correctly aligned

- Inspect seals and gaskets for leaks and wear

- Assess the condition of bearings

- Ensure that all moving parts are correctly lubricated

- Inspect electrical connections, wiring and motor controls to ensure they are in good working condition and free from defects

- Check the functionality of safety devices and alarms

- Examine piping system for leaks, corrosion or blockages

- Perform vibration analysis to identify any abnormal vibrations that may indicate underlying issues

- Review maintenance records and documentation to ensure that maintenance activities are up to date and in compliance with safety standards

Conclusion

At Tapflo UK, we’re committed to delivering reliable and versatile pump solutions that prioritise safety in various industries. We encourage you to implement the safety tips outlined in this blog, ensuring you protect your personnel, equipment and the environment while ensuring the efficiency and longevity of your Centrifugal Pump systems.

Looking for more information about Centrifugal Pumps? Explore the remarkable benefits and uses of these workhorses in our Comprehensive Guide to Centrifugal Pumps.