Lobe pumps by Tapflo UK offer gentle, low-shear handling, making them ideal for maintaining product quality and integrity. Engineered to meet the highest hygiene standards, they are suited to pump products in the food, cosmetic, and pharmaceutical industries.

Max. Solids (mm)

60

Max. Temperature (C)

140°

Max. Pressure (m)

15

Max. Capacity

110m³/hr

EHEDG Lobe Pump

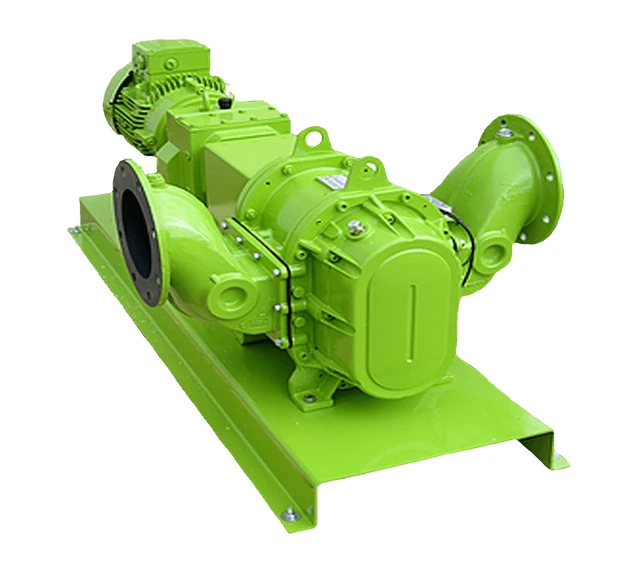

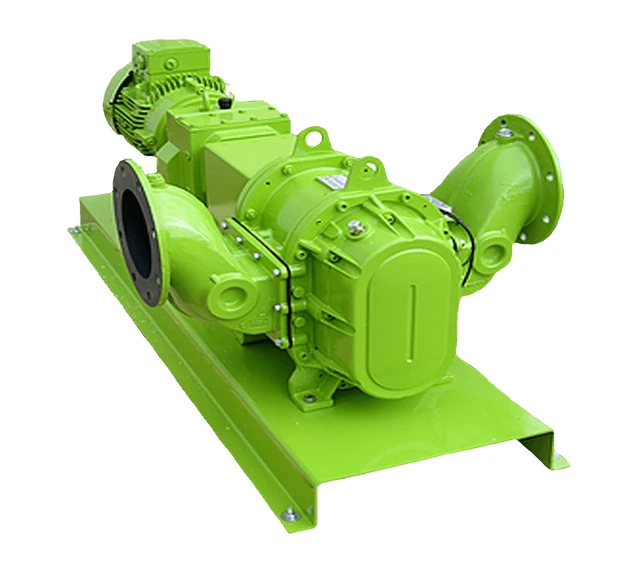

Max. Solids (mm)

30

Max. Temperature (C)

40°

Max. Pressure (m)

50

Materials

Stainless Steel and Cast Iron

Max. Head (m)

50

Industrial Rubber Rotary Lobe Pump

Max. Solids (mm)

15

Max. Temperature (C)

40°

Max. Pressure (m)

10

Materials

Stainless Steel

Max. Head (m)

100

Hygienic Lobe Pump

Lobe pumps are a type of Positive Displacement Pump that contains two rotating lobes. The lobes create a suction, drawing fluid into the pump and creating pressure to transfer fluid out.

Capable of withstanding temperatures up to 140°C, these pumps support both CIP and SIP processes, and are available with EHEDG certification, FDA approval, and ATEX-compliant variants, offering a versatile and reliable solution for demanding applications.

We pride ourselves on our exceptional engineering standards

Tapflo UK have over 2 decades of expertise in selling, manufacturing, servicing and engineering a wide range of top-quality pumps. We deliver comprehensive solutions across almost every industry. We provide lobe pumps that offer an ideal solution for a variety of applications, particularly when handling high-viscosity fluids or those containing solids.

How do Lobe Pumps work?

Lobe Pumps, also known as Rotary Lobe Pumps, are a type of Positive Displacement Pump featuring two or more rotating lobes. The lobes rotate to create a suction inside the pump, which draws fluid through the inlet. The pressure builds up inside the pump and, in turn, forces the fluid out the other side of the pump through the discharge outlet. The lobes don’t touch each other, which aids the hygienic application.

What materials are Lobe Pumps made from?

Lobe Pumps are available in Stainless Steel AISI 316L and Cast Iron. They can also be supplied in different elastomers, including NBR, SBR, XNBR, EPDM, Viton, Teflon, FPM, FKM etc. Some materials offer ATEX options on request, for explosive applications and environments.

Are Lobe Pumps suitable for shear-sensitive fluids?

Yes, they produce a gentle pumping effect, handling highly viscous products and those containing solids, making them suitable for shear-sensitive fluids.

What is the difference between Lobe Pumps and Centrifugal Pumps?

Lobe Pumps are ideal for high-viscosity fluids and those requiring low-shear pumping. Whereas Centrifugal Pumps are better suited for high-volume applications with low to medium viscosity fluids.

What is the difference between Lobe Pumps and Gear Pumps?

Lobe pumps operate using two or more rotating lobes that create a vacuum, drawing fluid into the inlet and pushing it out through the discharge port. They are ideal for handling viscous fluids gently, without causing damage. In contrast, gear pumps use interlocking gears to trap and move fluid through the pump, making them well-suited for high-pressure applications involving low to medium-viscosity fluids.

Are Lobe Pumps suitable for fragile solids?

Yes, they are suitable for handling solids of up to 60mm in some models, and their low shear forces make an ideal pumping solution for fragile solids.

Can Lobe Pumps run dry?

They can run dry intermittently, but it’s not recommended. However, pumps with flush double mechanical seals can run dry continuously.

What are common applications of Lobe Pumps?

How do you maintain a Lobe Pump?

You should check the oil level in the gearbox periodically, replacing the oil after the first 100 hours of use, then change it around once a year.

Other factors to consider

Lobe pumps are available in vertical and horizontal executions and a series of mobile solutions, to fit your operation regardless of the orientation or set-up.

Call us:

02380 252 325Email us:

enquiries@tapflopumps.co.ukContact our experts today for further information

If you are having trouble finding the suitable pump for your needs please contact

02380 252 325