Pumping chocolate can be a challenge due to its high viscosity, sensitivity to temperature, and the potential presence of suspended solids, such as nuts. As a leading manufacturer of process pumps and systems, Tapflo UK offers a variety of sanitary pumps designed to overcome these challenges, ensuring efficient and hygienic solutions for chocolate production. Below, we’ll explore the most suitable pumps for chocolate and the key considerations when selecting the right pump for your needs.

What is the Maximum Viscosity of Chocolate that we can Pump?

Chocolate can reach viscosities as high as 50,000 centipoise (cP) at room temperature. However, most manufacturers pump chocolate at around 50°C, reducing the viscosity to approximately 25,000 cP. Tapflo UK can spec pumps that handle viscosities up to 50,000 cP, but we generally recommend pumping chocolate at elevated temperatures to ensure smoother flows and less strain on your equipment.

Best Pump Types for Pumping Chocolate

We offer a range of pumps suitable for chocolate processing, including Lobe Pumps, Twin Screw Pumps, and Progressive Cavity Pumps to name a few. Each type has distinct advantages depending on the specific application.

Lobe Pumps:

- Advantages: Lobe Pumps are ideal for handling high-viscosity fluids and shear-sensitive products, like chocolate. They offer smooth, pulse-free flow, making them a great choice for maintaining the consistency of chocolate. They are also highly compatible with Clean in Place (CIP) systems, which simplifies maintenance

- Best for: Pumping thick chocolate and chocolate with suspended solids like nuts, especially in applications where hygiene and product integrity are key

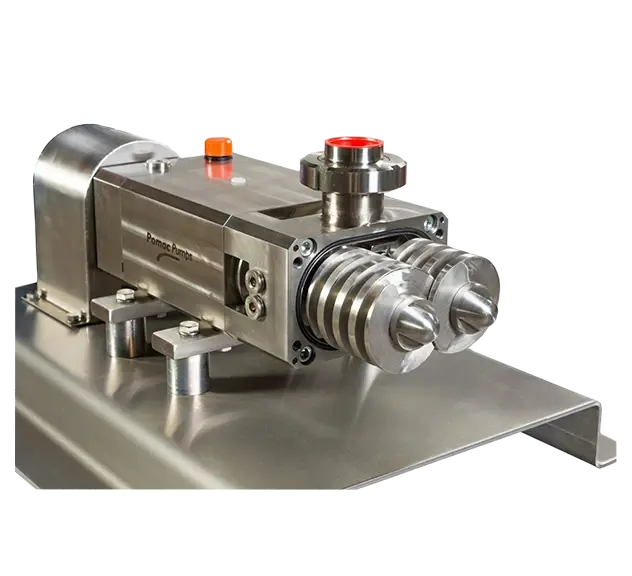

Twin Screw Pumps:

- Advantages: Twin Screw Pumps are becoming increasingly popular for chocolate applications due to their ability to handle both the product and the CIP cleaning fluid, eliminating the need for a second pump. They provide superior priming capabilities, making them suitable for applications where the pump needs to handle both liquid and gas phases

- Best for: When flexibility is important, as they can pump a range of fluids, from low to high viscosity, and are excellent for mixed phases (liquid/gas)

Hygienic Progressive Cavity Pumps:

- Advantages: Hygienic Progressive Cavity Pumps are also excellent for handling viscous materials like chocolate. They provide a steady, non-pulsating flow and are great for maintaining product integrity. This pump type works well when there’s a need for metered, consistent flow at variable pressures

- Best for: Applications where maintaining a very steady flow is essential, such as dosing chocolate into moulds or filling lines

Gear Pumps:

- Advantages: Designed specifically for the chocolate industry, the ROTAN® Internal Gear Pump is tailored for handling media with very high viscosity, such as cacao mass, milk chocolate, and caramel cream. It features a unique internal gear design with T2 tolerance and a chocolate seal, which ensures careful treatment of the product both mechanically and in terms of temperature control. This pump is known for its reliability and ability to prevent seizures while reducing maintenance and housekeeping efforts

- Best for: High-viscosity chocolate products, including cacao mass, conched chocolate, white chocolate with sugar, and finished chocolate after tempering

Sanitary Diaphragm Pumps:

- Advantages: Though not as common for chocolate, Sanitary Air Operated Diaphragm Pumps can be used for some chocolate applications, particularly when it comes to transferring fluid over long distances or where self-priming is important. They can also handle some solids without damage

- Best for: Low-viscosity chocolate or chocolate liquids with short transfer needs

Key Benefits of Tapflo UK Pumps for Chocolate

- Hygienic Design: Our sanitary pumps, including lobe and twin screw types, are EHEDG compliant and built from 316L Stainless steel, ensuring compliance with strict food-hygiene standards

- Versatility: Our pumps are highly flexible, capable of pumping low and high-viscosity fluids. Both Lobe and Twin Screw Pumps can handle a wide range of chocolate products, including those with suspended solids, while maintaining consistent quality

- Efficient Operation: Low-speed operation (especially below 100 rpm for chocolate) ensures that chocolate is not damaged by shear forces or high temperatures, which could lead to caramelisation or clogging

- Ease of Maintenance: Tapflo UK Pumps are designed with user-friendly features, such as quick-release seals and front pull-out designs, making maintenance simple and efficient. For chocolate, tungsten carbide mechanical seals are recommended due to their resistance to wear from abrasive particles

Can I Pump Chocolate with Suspended Solids?

Yes, both Lobe Pumps and Twin Screw Pumps can handle chocolate with suspended solids, such as nuts or caramel pieces, without damaging the product. Bi-Wing lobes in Lobe Pumps are specifically designed to accommodate larger solids while minimising damage. Similarly, Twin Screw Pumps can handle solids while maintaining product integrity due to their gentle handling of the fluid.

How to Maintain Chocolate Temperature During Pumping?

Maintaining the correct temperature when pumping chocolate is crucial to avoid crystallisation or solidification, which can block the pump and reduce efficiency. Tapflo UK offers heating jackets that can be fitted to the pump body and front cover. This ensures that the chocolate remains at the optimal temperature as it moves through the pump. Heating jackets are particularly important for high-viscosity or thick chocolate that needs to remain fluid.

Protecting Your Pump: Best Practices for Chocolate Applications

- Slow Pump Speeds: Chocolate is sensitive to high shear forces and heat, so slow speeds (below 100 rpm) are crucial to prevent caramelisation and product degradation. This is especially important for chocolate with high sugar content

- Use Abrasion-Resistant Parts: For chocolate with abrasive solids, we can provide pumps with FDA-approved hardening treatments, extending the life of components such as lobes and seals

Choosing the Right Seals for Chocolate

Selecting the right seal for chocolate applications is critical. Tapflo UK offers several seal options, all compliant with FDA and EC-1935/2004 standards:

- Single Mechanical Seal (Tungsten Carbide): Ideal for high-viscosity chocolate and abrasive products. It is durable and handles higher pressures

- Double Mechanical Seal: For applications with a risk of dry running, a double mechanical seal with food-grade lubrication is ideal

- Double O-Ring Seal: An economical option for lower-pressure applications, this seal type also requires food-grade lubrication

Maintenance for your Chocolate Pump

Regular maintenance ensures optimal pump performance and longevity. Key tasks include monitoring for excessive noise, checking oil levels, and ensuring that suction and discharge pressures are within standard limits. We recommend an initial oil change after 300 hours of operation, followed by changes every 3000 hours or three months.

Tapflo UK Chocolate Pump Case Study

We recently worked with a large chocolate manufacturer in the UK that needed to transfer hot chocolate from a holding tank to a filling machine. The project specifications were as follows:

- Fluid: Chocolate

- Viscosity: 20,000 cP (approx.)

- Flow Rate: 8m³/h

- Temperature: 52°C

- Solids: None

- Pipework: 2-inch

- Discharge Length: 28.5 meters

- Suction Condition: Flooded

We selected a Sanitary Lobe Pump with 316L Stainless Steel Lobes and a 2-inch Tri-Clamp connection. A heating jacket wasn’t necessary due to the short discharge distance. The pump was connected to a CIP system for ease of cleaning after each use. The installation was seamless, and the pump has been running efficiently since.

Tapflo UK provides a wide range of pumping solutions for chocolate, each offering unique benefits tailored to specific needs. Whether you’re looking to maintain high product quality, handle solids, or ensure smooth flow, Tapflo UK’s pumps are designed to meet the challenges of chocolate production.

Contact us today to find the perfect pump solution for your chocolate processing needs.