| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| VA-INV | 72 | 40 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| VA-INV | 72 | 40 |

How does a VA & INV Flexible Impeller Pump work?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

How does this differ from other products on the Tapflo website?

What applications are suited to this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with highest-quality Flexible Impeller Pumps.

Our VA & INV Flexible Impeller Pumps is ideal for transfer, filling, dosing and filtration applications that require variable speed control. It can handle not only clean, light fluids, but also viscous, solid-laden slurries, with solids passage capabilities up to 25mm.

The VA Series offers the capability to adjust its speed through its integral mechanical variator, which changes the mechanical output speed of the gearbox.

Typical applications for our VA & INV Flexible Impeller Pumps:

Download Brochure

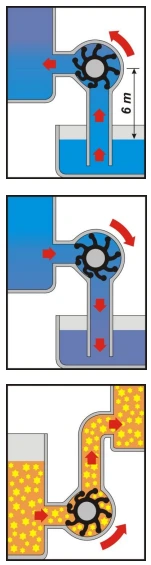

These flexible impeller pumps, also known as vane pumps, are a form of positive displacement pump, they move fluid from the suction to discharge port by trapping fluid between its impeller vanes and forcing it out.

Our VA Series is characterised by its ability to adjust its speed by its integral mechanical variator, which changes the mechanical output speed of the gearbox. Flow control isn’t as accurate as the INV series. However, it provides a decent flow range for applications where precise flow control isn’t necessarily required. Speed adjustment must be done whilst the pump is at a standstill, not during operation.

All VA series units are 3 phases as standard.

Our INV Series provides the widest and most accurate flow control as you can infinitely vary the speed of the motor between its min and max speed points by using the pre-wired and calibrated inverter panel. As with the RID series, the INV MAXI DOUBLE 2Q doubles the flow of the INV MAXI 80 & INV MAXI DOUBLE 2H doubles the head.

As standard, the INV Series is supplied trolley mounted and with a CE Control Panel with an integral inverter, remote control on a 15 m cable with on/off/reverse & Speed Adjustment, dry-run protection & supplementary 24V NC Contactor for wiring to any additional fluid accessories such as Flow Meters, Pressure Switches or Transducers etc.

The feeding supply for the INV series can be either 230V single phase (up to 2.2 kW) or 230-400V three-phase.

These flexible impeller pumps, also known as vane pumps, are a form of positive displacement pump, they move fluid from the suction to discharge port by trapping fluid between its impeller vanes and forcing it out.

Our VA Series is characterised by its ability to adjust its speed by its integral mechanical variator, which changes the mechanical output speed of the gearbox. Flow control isn’t as accurate as the INV series. However, it provides a decent flow range for applications where precise flow control isn’t necessarily required. Speed adjustment must be done whilst the pump is at a standstill, not during operation.

All VA series units are 3 phases as standard.

Our INV Series provides the widest and most accurate flow control as you can infinitely vary the speed of the motor between its min and max speed points by using the pre-wired and calibrated inverter panel. As with the RID series, the INV MAXI DOUBLE 2Q doubles the flow of the INV MAXI 80 & INV MAXI DOUBLE 2H doubles the head.

As standard, the INV Series is supplied trolley mounted and with a CE Control Panel with an integral inverter, remote control on a 15 m cable with on/off/reverse & Speed Adjustment, dry-run protection & supplementary 24V NC Contactor for wiring to any additional fluid accessories such as Flow Meters, Pressure Switches or Transducers etc.

The feeding supply for the INV series can be either 230V single phase (up to 2.2 kW) or 230-400V three-phase.

The VA & INV Flexible pumps offer many benefits which include:

| Max Capacity (m³/hr) | 72m³/hr |

| Max Pressure (m) | 40m |

| Max Temperature (°C) | 100°C |

| Max Viscosity (cP) | 50 cP |

| Self-Priming | Up to 6m |