| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| INV-BS | 22.5 | 32 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| INV-BS | 22.5 | 32 |

How does an Inverter Drive Flexible Impeller Pump work?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

How does this differ from other products on the Tapflo website?

What applications are suitable for this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with highest-quality Flexible Impeller Pumps.

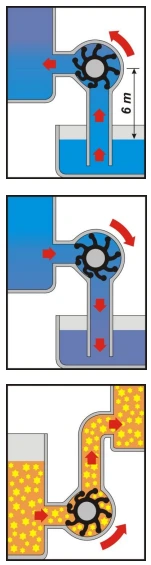

Our Inverter Drive Self-Priming Flexible Impeller Pump has been designed as a simplified and more cost-effective alternative to the INV Series. This model excels in the transfer of sensitive and delicate fluids, including viscous substances and suspended solids up to 25mm. It features 3 close-coupled pumps, fitted with forced-ventilated motors on a trolley system.

Typical applications for our Inverter Drive Flexible Impeller Pump:

Download Brochure

Our INV-BS Self-Priming Flexible Impeller Pump Series is characterised by featuring either the close-coupled MINOR 40 or MAJOR 60 pump units fitted with forced-ventilated motors onto a 2-wheel trolley system. All flow control is located on the control panel.

The INV-BS is a cost-effective alternative to the INV series, which you can find here: VA & INV Self Priming Flexible Impeller Pumps.

Due to the 4 kW inverter drive system, the feeding supply for both models needs to be 400V three-phase. Manual or Spring Loaded By-Passes are also available on request.

Our INV-BS Self-Priming Flexible Impeller Pump Series is characterised by featuring either the close-coupled MINOR 40 or MAJOR 60 pump units fitted with forced-ventilated motors onto a 2-wheel trolley system. All flow control is located on the control panel.

The INV-BS is a cost-effective alternative to the INV series, which you can find here: VA & INV Self Priming Flexible Impeller Pumps.

Due to the 4 kW inverter drive system, the feeding supply for both models needs to be 400V three-phase. Manual or Spring Loaded By-Passes are also available on request.

The inverter drive flexible impeller pump offers many benefits to the user, including:

| Max Capacity (m³/hr) | 22.5m³/hr |

| Max Pressure (m) | 32m |

| Max Temperature (°C) | 100°C |

| Max Viscosity (cP) | Up to 50,000 cP |

| Outlet Sizes | 1″ BSP F to 2½” RJT |