| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| MAJOR 5-120 | 12000 | 18 |

| MAJOR 10-200 | 22500 | 18 |

| MAXI 20-300 | 36000 | 18 |

| MAXI 20-400 | 43800 | 18 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| MAJOR 5-120 | 12000 | 18 |

| MAJOR 10-200 | 22500 | 18 |

| MAXI 20-300 | 36000 | 18 |

| MAXI 20-400 | 43800 | 18 |

How does an All-in-One Flexible Impeller Pump work?

How does this differ from other products on the Tapflo website?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

What typical fluids are pumped via this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

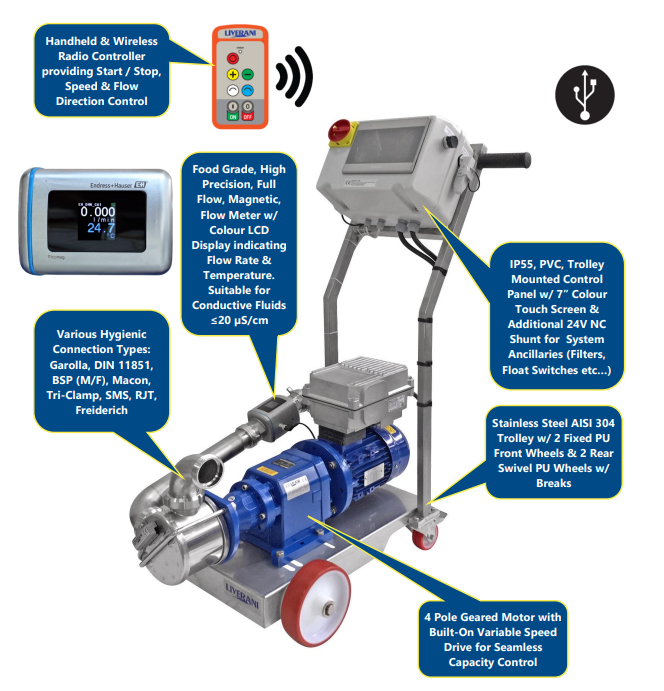

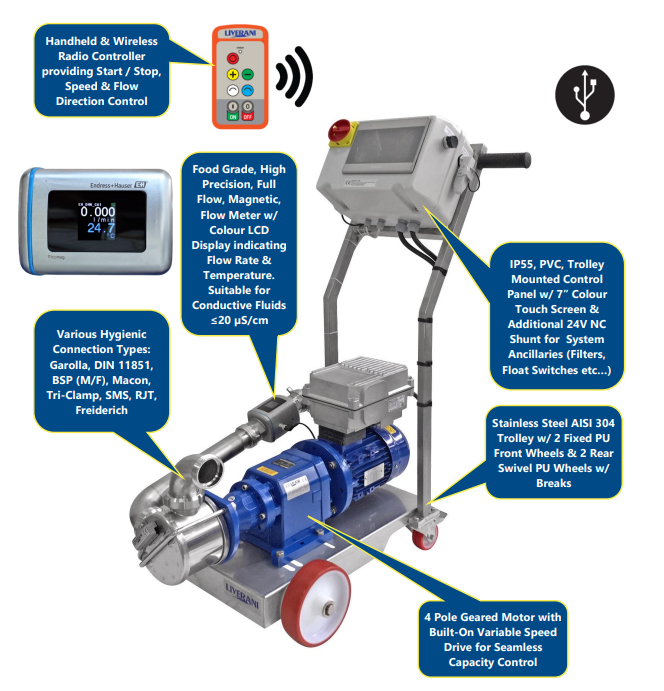

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with high-quality Flexible Impeller Pumps.

The All in One Flexible Impeller Pump is based on the features of the INV Series. It is a complete system that's designed for efficient wine transfer and food-grade applications, this Flexible Impeller Pump features a 7" colour touch screen that allows the operator to review current transfer data, schedule volumes and analyse previous operations.

Built onto a Stainless Steel trolley, this pump features a high-precision magnetic food-grade flow meter, remote control for speed variation, inversion rotation and start/stop. Additionally, the impellers can handle solids such as grape seeds and skins, making it an excellent option for a wine transfer.

Download Brochure

All-In-One Flexible Impeller Pump is an intelligent pump that allows the user to organise, monitor, and schedule fluid transfer operations.

Through a multi-function touch control panel, the user can view the transfer data in progress, program the volumes to be transferred and record operations (traceability).

From a simple intuitive menu, the operator can perform the following operations:

Free Transfer: Transferring by displaying the flow rate in l/min, l/h, hl/h, Us Gal/min, or Us Gal/h.

Filling: A quantity of wine is preselected, and once the target speed and a volume is reached, the pump will stop at the entered target value.

Barrel Filling: Repeated filling via programmed volumes, starting from touch or from the remote control.

Pump-Over: Automatic work/pause cycles can be programmed, with a pipe-emptying function included.

Traceability: Data can be recorded and saved, including the type of wine and reference batch.

Diagnostics: The diagnostics section allows you to view any inverter errors on the page, any stops due to dry-stop intervention, or via auxiliary contact intervention.

For units fitted with the DN50 size flow meter, it’s possible to download the flow meter OI-Link app to view current capacity & temperature on your smartphone.

All-In-One Flexible Impeller Pump is an intelligent pump that allows the user to organise, monitor, and schedule fluid transfer operations.

Through a multi-function touch control panel, the user can view the transfer data in progress, program the volumes to be transferred and record operations (traceability).

From a simple intuitive menu, the operator can perform the following operations:

Free Transfer: Transferring by displaying the flow rate in l/min, l/h, hl/h, Us Gal/min, or Us Gal/h.

Filling: A quantity of wine is preselected, and once the target speed and a volume is reached, the pump will stop at the entered target value.

Barrel Filling: Repeated filling via programmed volumes, starting from touch or from the remote control.

Pump-Over: Automatic work/pause cycles can be programmed, with a pipe-emptying function included.

Traceability: Data can be recorded and saved, including the type of wine and reference batch.

Diagnostics: The diagnostics section allows you to view any inverter errors on the page, any stops due to dry-stop intervention, or via auxiliary contact intervention.

For units fitted with the DN50 size flow meter, it’s possible to download the flow meter OI-Link app to view current capacity & temperature on your smartphone.

The All-In-One Flexible Impeller pump offers many benefits to the end user which include:

Features exclusive to this model include:

Performance Table:

| Pump Type | DN | Feeding Supply | Power (kW) | Speed (rpm) | Head (m) | |||||||||

| 0 | 4 | 8 | 12 | 16 | 18 | Capacity (l.hr) | ||||||||

| All in One MAJOR 5-120 | DN40 | MF | TF | 2.2 | Min | 25 | 650 | 0 | ||||||

| 175 | 4320 | 3840 | 2800 | 0 | ||||||||||

| 350 | 9000 | 7800 | 6000 | 3700 | 0 | |||||||||

| Max | 470 | 12000 | 10500 | 8700 | 5100 | 0 | ||||||||

| All in One MAJOR 10-200 | DN50 | MF | TF | 2.2 | Min | 50 | 1230 | 0 | ||||||

| 175 | 4320 | 3840 | 2800 | 0 | ||||||||||

| 470 | 12000 | 10500 | 8700 | 5100 | 0 | |||||||||

| Max | 900 | 22500 | 19560 | 15000 | 11220 | 3000 | 0 | |||||||

| All in One MAXI 20-300 | DN50 | TF | 4.0 | Min | 25 | 2100 | 0 | 2800 | 1750 | 0 | ||||

| 150 | 12000 | 10000 | 7500 | 0 | ||||||||||

| 300 | 24600 | 22200 | 18900 | 12000 | 0 | |||||||||

| Max | 470 | 36000 | 34200 | 30000 | 24000 | 12000 | 0 | |||||||

| All in One MAXI 20-400 | DN65 | TF | Min | 50 | 3800 | 0 | ||||||||

| 150 | 12000 | 10000 | 7500 | 0 | ||||||||||

| 300 | 24600 | 22200 | 18900 | 12000 | 0 | |||||||||

| Max | 600 | 43800 | 41400 | 36000 | 33000 | 30000 | 16000 | |||||||