| Model (inc. ATEX) | Max Capacity (L/min) | Connections BSP inv. |

|---|---|---|

| T30 | 28 | 1" |

| T80 | 78 | 1" |

| T125 | 155 | 1 1/2" |

| T225 | 330 | 2" |

| T425 | 570 | 2 1/2" |

| T825 | 820 | 3" |

| Model (inc. ATEX) | Max Capacity (L/min) | Connections BSP inv. |

|---|---|---|

| T30 | 28 | 1" |

| T80 | 78 | 1" |

| T125 | 155 | 1 1/2" |

| T225 | 330 | 2" |

| T425 | 570 | 2 1/2" |

| T825 | 820 | 3" |

What Industries is this Pump Designed for?

Why is the Design Considered Hygienic?

What Product Contact Materials are Used?

Can this Pump be Used in ATEX-Rated Zones?

What are the Cleaning & Maintenance Advantages?

What Media Can this Pump Handle?

What Temperatures & Flow Rates Can this Pump Handle?

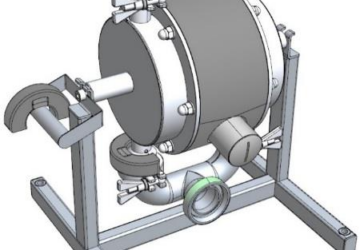

Our Sanitary Diaphragm Pump is part of our air-operated range and has been specially designed to meet the requirements of the Food, Beverage, Pharmaceutical and Cosmetic industries. The pump is FDA-approved, ATEX-rated, and can feature flap valves for liquids containing large solids or magnetic ball lifters for simple pump draining. Available in various executions to meet your operational requirements, these CIP and SIP capable pumps are self-priming, can handle solids up to 100m, and viscosities of 20,000 cPs.

Typical applications for our Sanitary Diaphragm Pump:

Download Brochure

Download Manual

Our Sanitary series of Diaphragm Pumps has been specifically designed to meet the requirements of the Food, Beverage, Pharmaceutical and Cosmetic industries, offering FDA, EHEDG, or USP VI certifications.

Our range of Diaphragm Pumps have been designed with simplicity and innovation in mind; they have a compact, robust and reliable design that makes them popular across the globe. Significant in hygienic industries, our pump range is quick and easy to maintain, keeping servicing costs and process downtime to a minimum. We have a range of Pneumatic Diaphragm Pump accessories available that provide control and monitoring capabilities, aiding in preventative and routine maintenance. This not only ensures your pump is operating efficiently but ensures our customers can optimise their systems to the best of their ability for accurate, precise and efficient performance.

Our Sanitary series of Diaphragm Pumps has been specifically designed to meet the requirements of the Food, Beverage, Pharmaceutical and Cosmetic industries, offering FDA, EHEDG, or USP VI certifications.

Our range of Diaphragm Pumps have been designed with simplicity and innovation in mind; they have a compact, robust and reliable design that makes them popular across the globe. Significant in hygienic industries, our pump range is quick and easy to maintain, keeping servicing costs and process downtime to a minimum. We have a range of Pneumatic Diaphragm Pump accessories available that provide control and monitoring capabilities, aiding in preventative and routine maintenance. This not only ensures your pump is operating efficiently but ensures our customers can optimise their systems to the best of their ability for accurate, precise and efficient performance.

The major features of our Sanitary Diaphragm Pumps include:

| Technical Data | Pump Size | |||||

| 30 | 80 | 125 | 225 | 425 | 825 | |

| Max Capacity (l/min) | 28 | 78 | 155 | 330 | 570 | 820 |

| *Volume per Stroke (ml) | 40 | 135 | 315 | 1000 | 2300 | 3281 |

| Max Discharge Pressure (Bar) | 8 | 8 | 8 | 8 | 8 | 8 |

| Max Air Pressure (Bar) | 8 | 8 | 8 | 8 | 8 | 8 |

| **Max Suction Lift Dry (m) | 2 | 3 | 4 | 5 | 5 | 4 |

| Max Suction Lift Wet (m) | 8 | 8 | 9 | 9 | 9 | 9 |

| Max Size of Solids (ø in mm) | 3 | 4/17*** | 6/17*** | 10/42*** | 15/42*** | 20/95*** |

| Max Temperature (°C) | 110 | 110 | 110 | 110 | 110 | 110 |

| Weight (kg) | 4 | 8 | 11 | 21 | 35 | 133 |

| Wetted Metal Details | Stainless Steel AISI 316L electro polished | |||||

| Centre Block (not wetted) | PP, PE Conductive | |||||

| Diaphragms | PTFE, PTFE with white back, EPDM, white EPDM, white NBR | PTFE/EPDM | ||||

| Valve Balls | PTFE, AISI 316, PU, Ceramic, PE1000 | |||||

| Air Valve | Brass (standard), Stainless Steel AISI 316L or PER with NBR (standard), EPDM or FKM o-rings | |||||

| Gaskets | PTFE or EPDM | |||||

| Housing Pin Screws | Stainless Steel | |||||

| Diaphragm Shaft | Stainless Steel AISI 316L (T30, T825)/304L (T80 – T425) | |||||

*The value is based on pumps with PTFE diaphragms (please contact us for other materials). It is recommended that the volume per stroke may vary depending on the pump’s operating parameters

**This is the max value with Stainless Steel Valve Balls, other valve ball materials mat reduce the suction

***Flap Valve execution – theoretical max solid size, the actual size may vary depending on the shape

Our Sanitary Air-Operated Double Diaphragm Pumps have a wide range of capacities to suit almost any application, from metering and dosing to general transfer. The max capacity range varies from 30 – 825 l/min with discharge pressures up to 8 bar as standard & standard solids passage up to 15 mm or 100 mm with Flap Valves.

Connections:

Our Sanitary Air Operated Double Diaphragm Pumps are supplied as standard with ISO Tri-Clamp connections. However, they may also be equipped with almost any type of connection used in the hygienic field – DIN clamps, SMS milk, RJT, DIN aseptic to mention a few.

Pump Emptying Procedure:

Modify your existing pump to be suitable for use with Magnetic Ball Lifters with the following additional parts:

Flap Valves –

Available on 3 pump sizes: T225, T425 & T825 Provide solids passage from 50 – 100 mm, model dependent. Provide Dry Suction Lifts up to 4.5 m Flap valves are a great option when the product to be pumped has a high viscosity and contains big solids or solids that can be damaged by standard valve balls (e.g. fruits).

Mounted with clamps they provide easy maintenance and cleaning. Made in AISI 316, they are mounted in a special flap valve cup with clamps between housing and manifold. Pumps with flap valves differ from the standard pump by valve type, manifolds and pump housing.

NOTE: Flap Valves are not appropriate for pumping water-like products. If a liquid has low viscosity, the valve will open and close very fast with no shock absorption that is provided by viscous products. Also, dry running of the pump for longer periods will cause rapid valve wear and eventually pump stopping. Modify your existing pump to be fitted with flap valves with the following additional parts:

Ball Cup Valves

This option is a perfect solution when there is a risk of damage to the valve seats from the product. If such a situation is to occur there is no need to replace the whole manifolds or housings, just the valve cup what drastically reduces the spare parts cost. Just like the flap valve it is made of AISI 316 stainless steel and is mounted between the housing and manifold with clamps. In the same way, the manifolds, pump housing and pump stand have to be changed in comparison to a standard sanitary pump. The following additional parts are required to optimise your pump to be fitted with ball cup valves:

Heating Jacket

A heating jacket is a great option when the pumped product tends to solidify at lower temperatures, e.g. chocolate or paraffin. When the pump has finished its duty and is left for some time without operation, the product can solidify inside. This is where the heating jacket comes in; before the next pump starts up, heat water or steam into the heating system for a defined period of time to melt the product inside the pump. Only then can the pump be started again with no risk of damage.

NOTE: When using steam as the heating agent, the flow must be from top to bottom (due to steam condensation). In the case of hot water or other liquid, it is the other way around. Do NOT exceed 2 Bar pressure in the jacket.

Magnetic Ball Lifters

Magnetic ball lifters are implemented in the Sanitary and Aseptic EHEDG series of AODD pumps to enable pump emptying without removing it from the installation when no other draining option is available. Rotating the pump is also no longer needed. The balls are lifted by simply attaching the magnets to the pumps manifold. Valve balls are available in AISI 420 magnetic stainless steel or PTFE with steel cores.