| Model (Inc. ATEX) | Max Capacity (L/min) | Connections BSP inv. |

|---|---|---|

| TXP120 | 158 | 1” |

| TXP220 | 330 | 1 1/2” |

| TXP420 | 570 | 2” |

| Model (Inc. ATEX) | Max Capacity (L/min) | Connections BSP inv. |

|---|---|---|

| TXP120 | 158 | 1” |

| TXP220 | 330 | 1 1/2” |

| TXP420 | 570 | 2” |

What Kind of Powders Can this Pump Handle?

How is it Different from Manual or Mechanical Powder Handling?

What is the Pump Housing & Wetted Material Made From?

Can this Pump be Used in ATEX Environments?

How Does this Pump Prevent Contamination?

Is the Powder Capacity Consistent Across Applications?

What Connection Sizes are Available?

Our TXP Powder Pump is an economical and compact alternative to many complex and large powder systems, and is designed to handle a range of industrial and sanitary process powders with specific weights from 80 - 720 kg/m³. Based on our standard Air Operated Diaphragm Pump, our ATEX-rated TXP Pump uses compressed air to drive 2 diaphragms, a design that prevents powder blockages. To ensure our Powder Pump is right for your application, a general rule is that if the powder does not clump together when squeezed in your hand, it can be used successfully. Due to the nature of powders, we will always trial a Powder Pump with your application first to ensure everything runs smoothly.

Typical applications for our Powder Pump:

Download Brochure

Download Manual

The innovative design of our Powder Pump not only means it can be portable, but also reduces the space requirement for powder transfer applications. The complexity and cost of installation, commissioning, and maintenance requirements are all reduced. The non-stick PTFE coating enables an efficient transfer through the pump with the least possible resistance.

What powders can our Powder Pump handle?

Our Powder Pump will handle different process powders, with specific weights from 80 to 720 kg/m³ dry weight. Generally, if the powder does not clump together when you squeeze it in your hand, the Tapflo Powder Transfer Pump can be used successfully. Examples of standard powders are sintering powder, carbon black, resins and silicones.

How does a Powder Pump work?

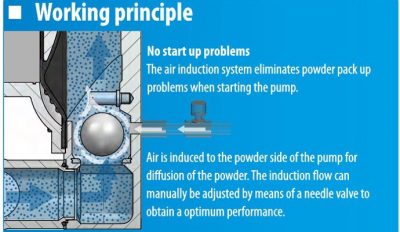

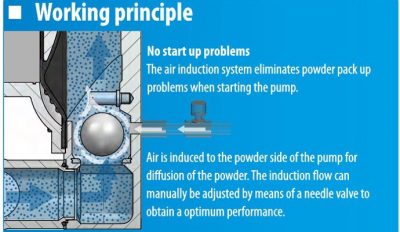

The TXP Powder Pump is hermetically transferred by means of the two diaphragms, which alternately prime the powder from the container in the first cycle and discharge to the process in the second cycle.

Learn more about the TXP Powder Pump in our ‘How to Pump Powder Applications‘ blog.

The innovative design of our Powder Pump not only means it can be portable, but also reduces the space requirement for powder transfer applications. The complexity and cost of installation, commissioning, and maintenance requirements are all reduced. The non-stick PTFE coating enables an efficient transfer through the pump with the least possible resistance.

What powders can our Powder Pump handle?

Our Powder Pump will handle different process powders, with specific weights from 80 to 720 kg/m³ dry weight. Generally, if the powder does not clump together when you squeeze it in your hand, the Tapflo Powder Transfer Pump can be used successfully. Examples of standard powders are sintering powder, carbon black, resins and silicones.

How does a Powder Pump work?

The TXP Powder Pump is hermetically transferred by means of the two diaphragms, which alternately prime the powder from the container in the first cycle and discharge to the process in the second cycle.

Learn more about the TXP Powder Pump in our ‘How to Pump Powder Applications‘ blog.

The major features of our Powder Pumps include:

Capacity

The capacity of the TXP Powder Pump is extremely different from one powder to another, depending on the consistency and weight of the powder. For more specific information about the capacity for your application, please get in touch with the team.

| Model | TXP70 | TXP120 | TXP220 | TXP420 | TXP820 |

| Inlet/Outlet Connections | 3/4″ BSP Thread (NPT on request) | 1″ BSP Thread (NPT on request) | 1 1/2″ BSP Threads (NPT on request) | 2″ BSP Threads (NPT on request) | 3″ BSP Threads (NPT on request) |

| Features | Complete air induction system included | ||||

| Explosion Protection | ATEX marked according to group IIG (gas)/IID (dust), category 2 | ||||

| Housing Material | PTFE-coated Aluminium | ||||

| Diaphragm Material | EPDM, NBR, PTFE | ||||

| Valve Ball | EPDM, NBR, AISI 316L, PU | ||||

| Inlet/Outlet Material | Stainless Steel AISI 316L or PTFE-coated Aluminium | ||||

| Max Pressure | 8 bar | ||||

| Max temperature | 110°C | ||||