| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| MINIVERTER | 5.76 | 32 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| MINIVERTER | 5.76 | 32 |

How does a Miniverter Flexible Impeller Pump work?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

How does this differ from other products on the Tapflo website?

What applications are for this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with highest-quality Flexible Impeller Pumps.

The Miniverter Flexible Impeller Pump, is characterised by its close-coupled design and comprises 2 models, the MINI and MIDEX units. These units offer the same sizing and performance capabilities as the EP range, with the addition of a potentiometer for variable speed range between 285-1400RPM and direction of flow.

These pumps deliver pulsation-free flows and can be rotated and installed in various positions for enhanced versatility.

Typical applications for our Miniverter Self-Priming Flexible Impeller Pumps:

Download Brochure

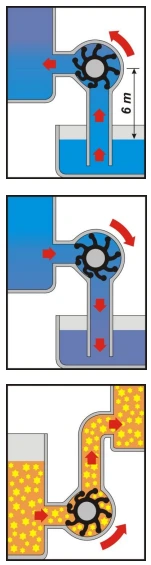

This self-priming flexible impeller pump is a form of positive displacement pump, moving fluid from the suction to discharge port by trapping liquid between impellers.

The MINIVERTER MINI & MINIVERTER MIDEX offer the exact sizing and performance range as their EP counterparts; however, in addition to having an on / off / reversing switch on the terminal box, there is also a potentiometer which allows for variable speed control. Combined with their SS316 construction and various impeller & sealing materials, the result is the most versatile utility pump available today.

Speed range adjustment is from 285 – 1400 rpm, and optional manual and spring-loaded by-passes are available on request, along with U or L shaped Carrying Handles or Trolleys.

The feeding voltage is 230V/1 Ph/50 Hz which means that you have a portable pump which is capable of dry suction lifts up to 6 m, reversible. Variable flow, multiple pump head and mounting configurations, and solids handling are suitable for both thin and viscous liquids that can be plugged into a standard household plug socket. What could be easier!

This self-priming flexible impeller pump is a form of positive displacement pump, moving fluid from the suction to discharge port by trapping liquid between impellers.

The MINIVERTER MINI & MINIVERTER MIDEX offer the exact sizing and performance range as their EP counterparts; however, in addition to having an on / off / reversing switch on the terminal box, there is also a potentiometer which allows for variable speed control. Combined with their SS316 construction and various impeller & sealing materials, the result is the most versatile utility pump available today.

Speed range adjustment is from 285 – 1400 rpm, and optional manual and spring-loaded by-passes are available on request, along with U or L shaped Carrying Handles or Trolleys.

The feeding voltage is 230V/1 Ph/50 Hz which means that you have a portable pump which is capable of dry suction lifts up to 6 m, reversible. Variable flow, multiple pump head and mounting configurations, and solids handling are suitable for both thin and viscous liquids that can be plugged into a standard household plug socket. What could be easier!

| Max Flow (m³/hr) | 5.76m³/hr |

| Max Pressure (m) | 32 |

| Max Temperature (°C) | 100°C |

| Max Viscosity (cPs) | 50,000 cPs |

| Outlet Sizes | ¾” BSP M up to 1½” RJT |