| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| EP Series | 43.8 | 32 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| EP Series | 43.8 | 32 |

How does the EP Flexible Impeller Pump work?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

What applications are for this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with highest-quality Flexible Impeller Pumps and Liquid Ring Pumps.

Our EP Flexible Impeller Pump, is a Self-Priming Pump and is the most commonly used Flexible Impeller Pump in our range. Characterised by its close-coupled design, this pump delivers reversible and pulseless flows, dry suction lift up to 6m and solids passage between 3 - 25mm. An on/off/reversing switch can be located on the terminal box of its motor for enhanced versatility. Additionally, this pump can be fitted with carrying handles (U and L-shaped) or trolleys (Zinc-coated Iron & Stainless-Steel 304), making it a highly versatile and efficient utility pump.

Typical applications for our EP Self-Priming Flexible Impeller Pump:

Download Brochure

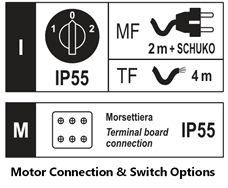

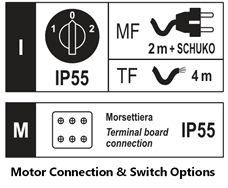

EP Self-Priming Flexible Impeller Pumps (also known as flexible vane pumps) are characterised by their close-coupled design and integral on/off/reversing switch on the terminal box of the motor, available in both single and three-phase. Upon request, three-phase units can also be supplied with terminal board connections for hard-wiring into the installation.

They are one of the most commonly used types of Self Priming Flexible Impeller Pumps, ideal for transferring, filling & emptying applications in a plethora of industries, as they can also be fitted with carrying handles (U & L Shaped) or trolleys (Zinc Coated Iron & SS 304), which makes them a particularly versatile utility pump.

Manual & Spring Loaded By-Passes are available on request.

These pumps are typically used in the following industries:

Voltages: 12, 24 DC (Continuously Rated) & 110, 230 & 400V (1 & 3 Phase)

Speeds: 470, 600, 900 & 1400 rpm single & dual speed

Counter Connections: EP MINI & MIDEX Models are supplied with SS 304 & 316 Hose Connections as standard. Garolla to BSP F Reducers are available on request for other models.

EP Self-Priming Flexible Impeller Pumps (also known as flexible vane pumps) are characterised by their close-coupled design and integral on/off/reversing switch on the terminal box of the motor, available in both single and three-phase. Upon request, three-phase units can also be supplied with terminal board connections for hard-wiring into the installation.

They are one of the most commonly used types of Self Priming Flexible Impeller Pumps, ideal for transferring, filling & emptying applications in a plethora of industries, as they can also be fitted with carrying handles (U & L Shaped) or trolleys (Zinc Coated Iron & SS 304), which makes them a particularly versatile utility pump.

Manual & Spring Loaded By-Passes are available on request.

These pumps are typically used in the following industries:

Voltages: 12, 24 DC (Continuously Rated) & 110, 230 & 400V (1 & 3 Phase)

Speeds: 470, 600, 900 & 1400 rpm single & dual speed

Counter Connections: EP MINI & MIDEX Models are supplied with SS 304 & 316 Hose Connections as standard. Garolla to BSP F Reducers are available on request for other models.

| Max Flow (l/min) | 730 l/min |

| Max Pressure (m) | 32m |

| Solids Passage (mm) | 3, 5, 10, 15 & 25mm |

| Voltages | 12 & 24V DC 110, 230 & 400V (MF & TF) |

| No. of Speed Settings | 1 or 2 |

| Speeds (rpm) | 470, 600, 900, 1400 |

| Pump Heads | AISI 304 AISI 316 |

| Impellers | Natural Rubber (NR) Nitrile (NBR) Neoprene (CR) EPDM Silicone (VQM) |

| Shaft Sealing | Bi-Directional Single Mechanical Seal Ceramic / Graphite / NBR (Std.) SiC/SiC/EPDM Tungsten Carbide / Tungsten Carbide / Viton etc… |

| Connections | BSP M BSP F Garolla DIN 11851 Macon Tri-Clamp SMS BSM / RJT Friederich |