| Model | DIN 11851 (Male Thread) Inlet/Outlet | DIN 11851 Drain |

|---|---|---|

| CTS H C... | DN40 / DN40 | DN15 |

| CTS H D... | DN65 / DN50 | DN15 |

| CTS H E... | DN65 / DN50 | DN15 |

| Model | DIN 11851 (Male Thread) Inlet/Outlet | DIN 11851 Drain |

|---|---|---|

| CTS H C... | DN40 / DN40 | DN15 |

| CTS H D... | DN65 / DN50 | DN15 |

| CTS H E... | DN65 / DN50 | DN15 |

What Makes the CTS-H Suitable for Hygienic Applications?

What Makes this Pump Self-Priming?

What Types of Liquids can the CTS-H Handle?

What are Common Applications of this Pump?

What Material Options are Available?

What Seal Options are Available?

Is the CTS-H Easy to Maintain?

Our Hygienic Self Priming Centrifugal Pump has been designed for Sanitary and Food-Grade applications. Constructed from AISI 316L Stainless Steel and surfaces electropolished to Ra <0.8, this pump meets the challenging demands of the Industrial, Food, Beverage and Pharmaceutical industries, handling fluids with viscosities up to 200 cSt and efficient solids-handling capabilities up to 6mm. With suction lift capabilities up to 4.5m, these ATEX-available pumps are well suited to various duties, including the transfer of CIP liquids.

Typical applications for our Hygienic Self Priming Centrifugal Pump:

Download Brochure

Download Manual

Our Hygienic Self Priming Centrifugal Pump (CTS H) is suitable for a wide variety of applications where a suction lift is required, or for pumping highly aerated fluids within the Industrial, Food, Beverage and Pharmaceutical industries. The CTS H Self Priming Centrifugal Pump is used in various hygienic applications, ideal for transferring or offloading multiple ingredients and products. As they can be ATEX rated, they can also be used for hazardous zones.

In their Hygienic form (CTS H), our Self Priming Centrifugal Pumps are ideally suited for the transfer or offloading of various ingredients and products like edible oil, flavourings, alcohol, dairy products and juice. There are also many auxiliary applications such as the transfer of CIP liquids, detergents and water. Rather than typically being used for tank-to-tank transfer applications, they can also be used for pressure boosting, dispensing, loading and offloading, tank cleaning, batching and metering, when used in conjunction with some of our control accessories.

Our Hygienic Self Priming Centrifugal Pump (CTS H) is suitable for a wide variety of applications where a suction lift is required, or for pumping highly aerated fluids within the Industrial, Food, Beverage and Pharmaceutical industries. The CTS H Self Priming Centrifugal Pump is used in various hygienic applications, ideal for transferring or offloading multiple ingredients and products. As they can be ATEX rated, they can also be used for hazardous zones.

In their Hygienic form (CTS H), our Self Priming Centrifugal Pumps are ideally suited for the transfer or offloading of various ingredients and products like edible oil, flavourings, alcohol, dairy products and juice. There are also many auxiliary applications such as the transfer of CIP liquids, detergents and water. Rather than typically being used for tank-to-tank transfer applications, they can also be used for pressure boosting, dispensing, loading and offloading, tank cleaning, batching and metering, when used in conjunction with some of our control accessories.

Sealing Options for our Hygienic Self Priming Centrifugal Pump

Standard Single Mechanical Seals are provided with a range of face materials, Ceramic / Graphite / SiC and O-Rings are available in EPDM / FKM / FFKM or FEP or alternatively, the seal can be provided with an OP-Ring (Square O-Ring). This increases the friction between the O-Ring and the back casing and therefore lowers the chances of the static parts of the seal from sticking together.

Lubricated & Externally Quenched Mechanical Seals can also be provided upon request and are ideally used when there is the potential for dry running or where there is a chance for the product to solidify or crystalise.

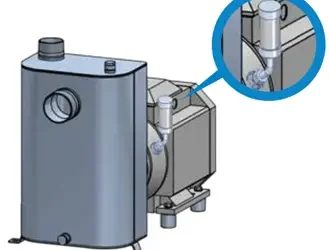

An oil pot is connected to the seal chamber and continually lubricates the seal during operation. SAE Grade 20 oil is recommended however you must use a fluid compatible with the pumped medium and materials within the pump. As an alternative, the CTH S can be supplied with ports to facilitate an external quench system.

This provides the added benefit of removing heat build-up from the seal face and doesn’t require changing the lubricating fluid. The max pressure of the quench circuit is 0.5 Bar and it’s recommended to install a thermo-syphon circulation into the quench circuit.

| Drive Type | Electric |

| Flow Rate | up to 58 m³/hr |

| Pressure | up to 40m |

| Material | Stainless Steel AISI 316L |

| Self-Priming | Yes |

| Solids Handling | up to 6mm |

| Viscosity | 0-200 cSt |

Materials & Limits

| Casing | Stainless Steel AISI 316L electropolished Ra <0.8 |

| Impeller | |

| Mechanical Seal | Single ceramic/graphite (standard), SiC/SiC or SiC/graphite, Optional with Lubrication or Flushing |

| O-Rings | EPDM FDA approved (standard), or FEP/silicone FDA approved |

| Motor | IP55; IEC frame B34; Available with ATEX cat 2 or 3; Eex e or Eex d |

| Pressure Rating | 100 meters (PN10) |

| Temperature | Max 90°C |

| Viscosity | Max ~200 cSt |

| Particles | Max diameter is 6 mm (std open impeller); bigger if soft particles |

Capacity range of the Hygienic Self Priming Centrifugal Pump

The CTS units are available with either 2 pole (high head applications) or 4 pole (low head applications) motors to provide a wide envelope of capacity.