Tailored & Bespoke

Engineering Expertise

Support & Training

Industrial Mixers, also known as IBC Mixers or IBC Agitators, and standard drum mixers are manufactured for use across the Industrial sector. Designed to efficiently re-mix product that has settled in an IBC (Intermediate Bulk Container) or drums, these mixers are a vital system for many industries that store and transport products in IBC’s/drums.

This simple and reliable mixing solution makes storing and transporting various liquids easy and cost-effective, and by using mixers, you’re able to skip the intermediate tanks, making your process quicker and more reliable.

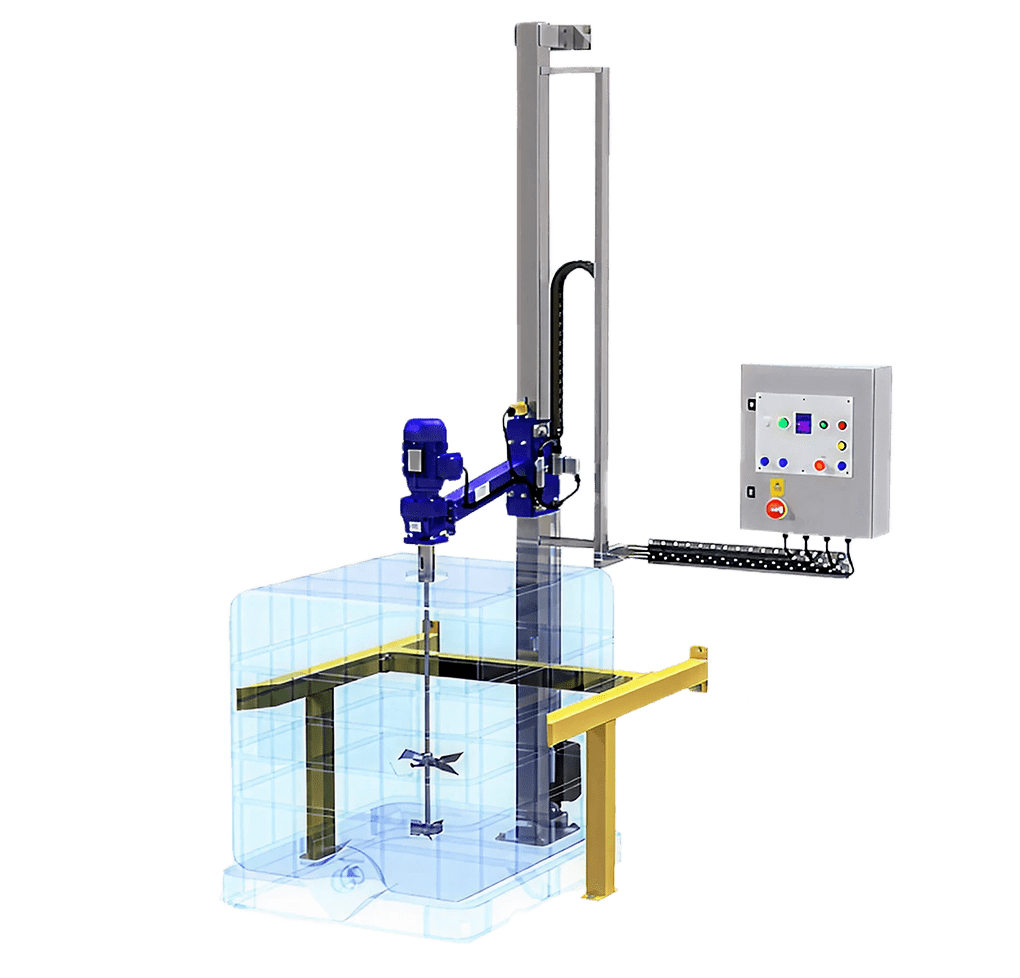

For optimal performance in any size or type of Intermediate Bulk Container.

Specifically designed to thoroughly mix liquids contained in IBCs.

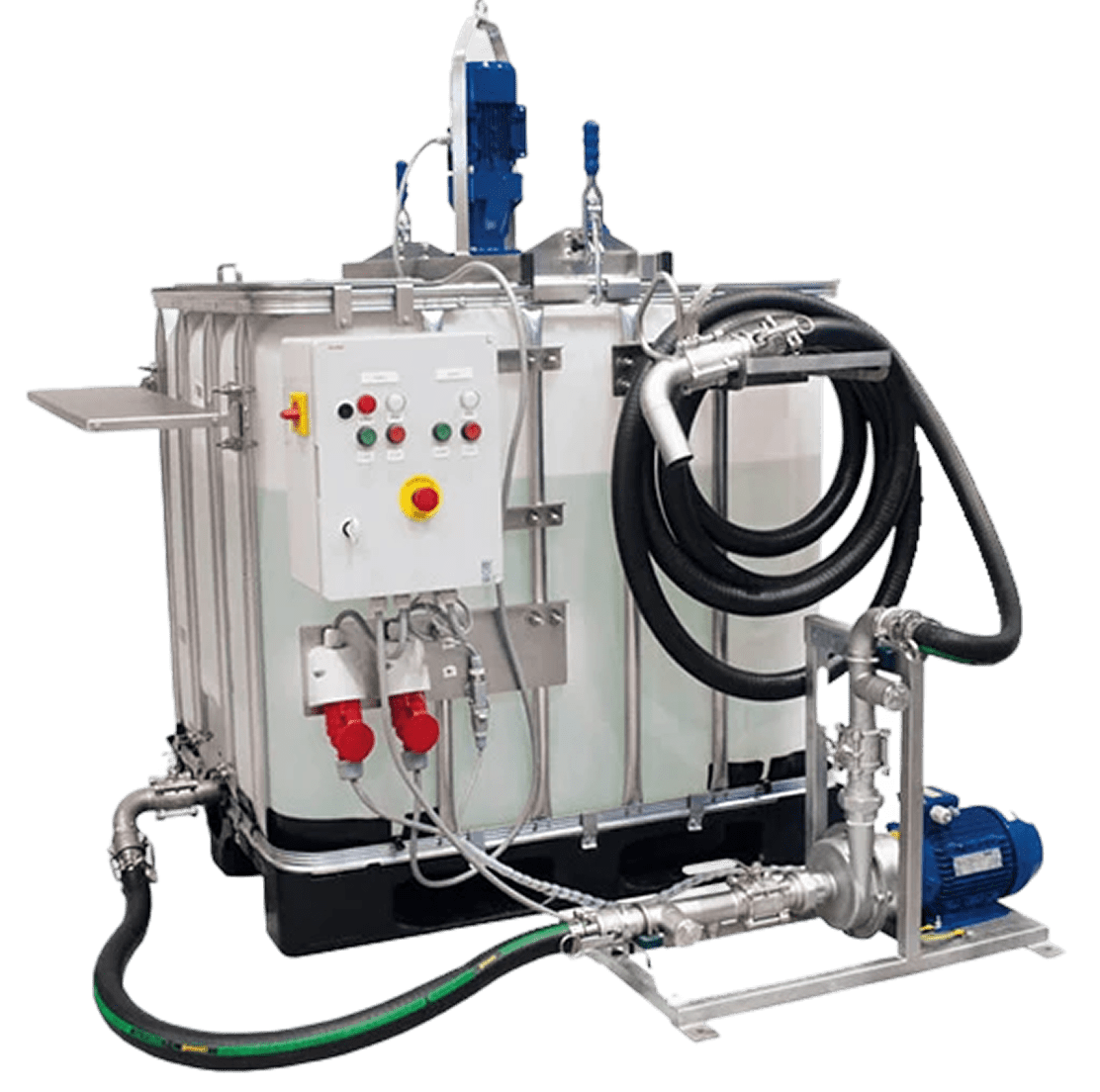

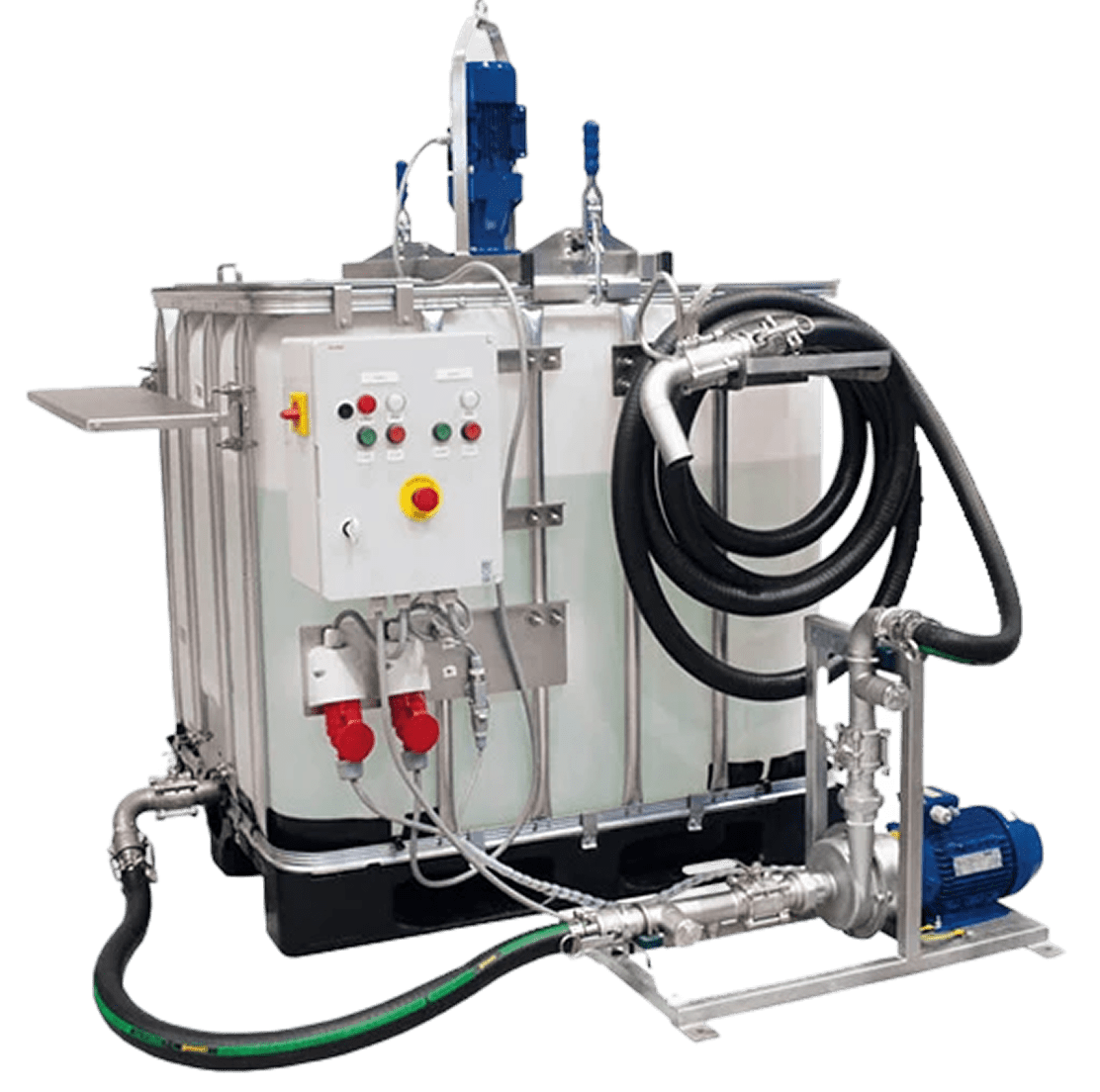

A 1000L tank-based system for both mixing and transferring fluids.

Increased productivity and reduced waste with Pneumatic Mixing & Emptying System

Industrial Mixers, also known as IBC Mixers or IBC Agitators, and standard drum mixers are manufactured for use across the Industrial sector. Designed to efficiently re-mix product that has settled in an IBC (Intermediate Bulk Container) or drums, these mixers are a vital system for many industries that store and transport products in IBC’s/drums.

This simple and reliable mixing solution makes storing and transporting various liquids easy and cost-effective, and by using mixers, you’re able to skip the intermediate tanks, making your process quicker and more reliable.

Our Industrial IBC (Intermediate Bulk Container) Mixers offer a simple, efficient solution for re-mixing settled liquids directly in IBCs or drums, eliminating the need for costly intermediate tanks:

All Tapflo Industrial Mixers ensure immediate and effective re-mixing of products that have settled in IBCs or drums over time. Some key benefits of using Industrial Mixers are:

Ready to mix efficiently? Talk to our team to explore mixers built to your needs Ready to mix efficiently? Talk to our team to explore mixers built to your needs

Industrial Mixers, also known as IBC Mixers or IBC Agitators, and standard drum mixers are manufactured for use across the Industrial sector. Designed to efficiently mix product that has settled in an IBC (Intermediate Bulk Containers) or drums. This simple and reliable mixing solution makes storing and transporting various liquids easy and cost-effective, time-efficient and more reliable.

Tapflo offers drum mixers equipped with either electric or air-driven motors, available with a range of mixing blades or paddles. Our pneumatic mixing and emptying systems feature fully controllable pneumatic operation and control. We also provide IBC mixers and mixing stations suitable for a wide variety of applications.

The main benefits of industrial mixers are:

– Versatile: Compatible with a wide range of drum and IBC sizes and can be fitted with different blade types to suit various applications.

– Transportable: Lightweight and easy to move, meaning they can be transported and used in various locations. Installations can be mobile or stationary.

– Simple: Easy to operate with simple controls for speed settings and timers.

– Efficient: Mixers reduce the need for manual intervention for a time and cost-effective solution.

– Safe: ATEX models are available, so they can be used in hazardous environments. IBCs also include a safety interlock switch.

Common industries that use mixers include:

– Food & Beverage

– Cosmetics

– Pharmaceutical

– Chemical

– Construction

– Industrial

– Wastewater Treatment

Mixers are important to prevent and solve product settlement in IBC and drums, ensuring product consistency, reducing manual intervention and downtime.

Yes, some of our products/materials offer an ATEX option for explosive and hazardous environments.

The IBC mixers come with a safety interlock switch, which prevents operation when not fixed securely.