| Model (Dampener) | Peristaltic Pump Size (PT) | Max Air Pressure (Bar) |

|---|---|---|

| DPT 40 | PT 25, PT 32, PT 38, PT 40 | 15 |

| DPT 65 | PT 51, PT 60, PT 65 | 10 |

| DPT 100 | PT 80, PT 80L, PT 100 | 10 |

| DPT 125 | PT 125 | 10 |

| Model (Dampener) | Peristaltic Pump Size (PT) | Max Air Pressure (Bar) |

|---|---|---|

| DPT 40 | PT 25, PT 32, PT 38, PT 40 | 15 |

| DPT 65 | PT 51, PT 60, PT 65 | 10 |

| DPT 100 | PT 80, PT 80L, PT 100 | 10 |

| DPT 125 | PT 125 | 10 |

Our DPT Pulsation Dampener for Peristaltic Pumps is specifically designed to optimise your pump system by reducing pulsating flows, vibrations and hammering in the pipework by up to 80% by using pressure housing manufactured from Stainless Steel with a reinforced rubber hose. This results in a smoother and more consistent linear flow. This effective dampening capability delivers reduced downtime and maintenance costs as it minimises wear and tear of the system. Additionally, the design allows for simplified cleaning and maintenance procedures as only the inner part of the hose comes into contact with the pumped fluid. While designed for Peristaltic Pumps, these dampeners are suited to additional pump types.

Typical applications for our DPT Pulsation Dampener for Peristaltic Pumps:

Download Brochure

Pulsations are a common challenge with Peristaltic Pumps, occurring when the shoes release the hose after compression on the discharge side. As the compressed hose returns to its original shape, the volume at the pump’s discharge increases, causing pressure drops along the installations discharge line. This occurrence gives rise to undesirable pulsations, vibrations and hammering within the piping system.

Fortunately, our DPT Pulsation Dampeners have been designed to tackle these pulsations head-on, keeping them to a minimum. These dampeners use a compressed vessel with a reinforced hose filled with compressed air or nitrogen. This is to absorb and mitigate the pulses generated by the Peristaltic Pump. It’s important to note that although these dampeners have been designed for Peristaltic Pumps, they are suitable for additional pump types as well.

The lifetime of the hose in a Peristaltic Pump is significantly extended, ensuring long-term reliability and reducing maintenance costs, By minimising pulsations, the dampeners enhance the overall performance of your installation, promoting smooth and uninterrupted operations. For added convenience, these dampeners can be installed in either a vertical or horizontal position, accommodating the unique requirements of your pumping system.

Dampening effect:0

Pulsations are a common challenge with Peristaltic Pumps, occurring when the shoes release the hose after compression on the discharge side. As the compressed hose returns to its original shape, the volume at the pump’s discharge increases, causing pressure drops along the installations discharge line. This occurrence gives rise to undesirable pulsations, vibrations and hammering within the piping system.

Fortunately, our DPT Pulsation Dampeners have been designed to tackle these pulsations head-on, keeping them to a minimum. These dampeners use a compressed vessel with a reinforced hose filled with compressed air or nitrogen. This is to absorb and mitigate the pulses generated by the Peristaltic Pump. It’s important to note that although these dampeners have been designed for Peristaltic Pumps, they are suitable for additional pump types as well.

The lifetime of the hose in a Peristaltic Pump is significantly extended, ensuring long-term reliability and reducing maintenance costs, By minimising pulsations, the dampeners enhance the overall performance of your installation, promoting smooth and uninterrupted operations. For added convenience, these dampeners can be installed in either a vertical or horizontal position, accommodating the unique requirements of your pumping system.

Dampening effect:0

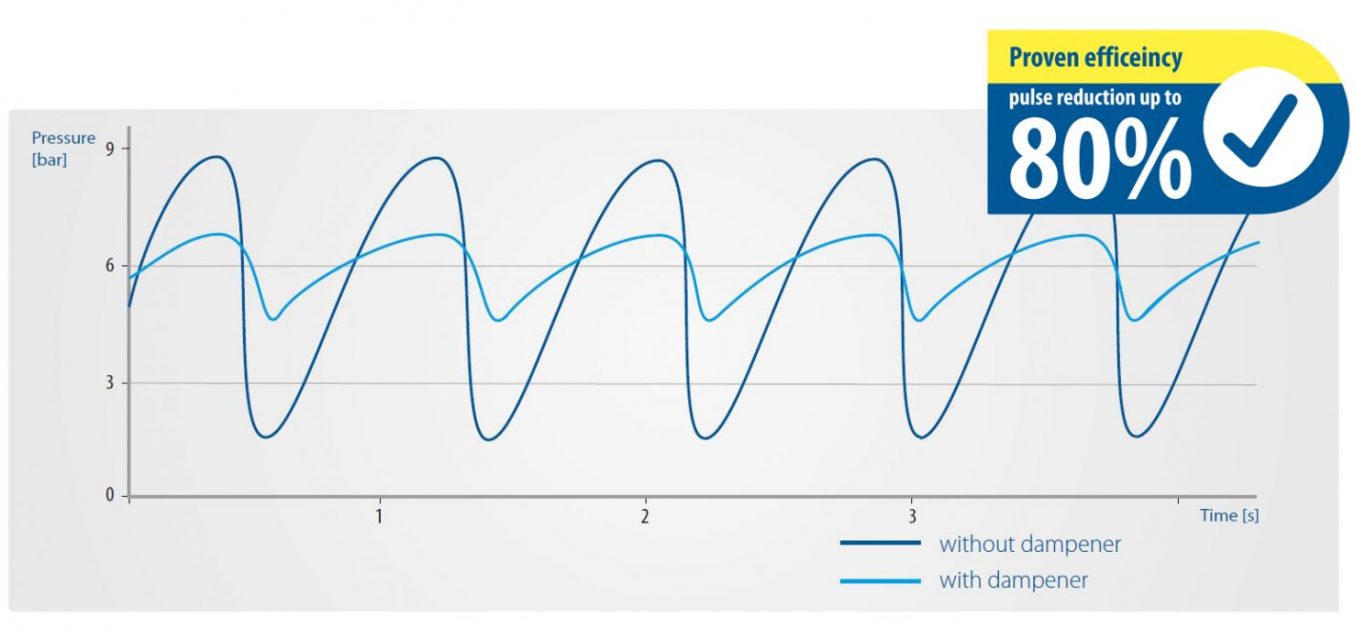

Dampening Effect:

The Pulsation Dampener installed at the pump outlet (light blue) decreases the flow pulsation when compared to one without it (shown in dark blue). This results in a proven pulsation reduction by up to 80%!

| Technical Data | DPT 40 | DPT 65 | DPT 100 | DPT 125 |

| Hose pump size | PT 25, PT 32, PT 38, PT 40 | PT 51, PT 60, PT 65 | PT 80, PT 80L, PT 100 | PT 125 |

| Max air pressure (bar/psi) | 15/217 | 10/145 | 10/145 | 10/145 |

| Max outlet pressure (bar/psi) | 15/217 | 10/145 | 10/145 | 10/145 |

| Min temperature (°C/°F) | -20/-4 | -20/-4 | -20/-4 | -20/-4 |

| Max temperature (°C/°F) | 80/176 | 80/176 | 80/176 | 80/176 |

| Dampener weight | 25/55 | 55/121 | 87/192 | 86/190 |

The following hose materials are available for each of these industries:

| Hose | ATEX | Industry | |||||||

| Water Treatment | Ceramic | Mining & Quarries | Building & Construction | Chemical | Food & Beverage | Paint, Pulp & Paper | Agriculture & Biogas | ||

| Industrial | |||||||||

| NR | x | x | x | x | x | x | x | x | |

| NBR | x | x | x | x | |||||

| EPDM | x | x | x | x | x | x | x | x | |

| CSM | x | x | x | x | |||||

| Food Grade | |||||||||

| NR FDA | x | x | |||||||

| NBR FDA | x | ||||||||

| EPDM FDA | x | ||||||||

Available connections include:

Pulsation Dampener video: