| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| S/P Range | 43.8 | 32 |

| Model | Max Capacity (m³/hr) | Max Pressure (m) |

|---|---|---|

| S/P Range | 43.8 | 32 |

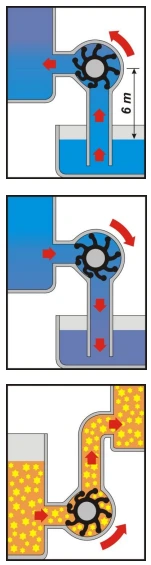

How does a Hydraulically Driven Flexible Impeller Pump work?

How does this differ from other products on the Tapflo website?

What is the difference between a Centrifugal and a Flexible Impeller Pump?

What applications are suited to this pump?

Are these pumps self-priming?

Can this pump run dry?

Is this pump suitable for abrasive or hazardous chemicals?

Tapflo UK is proud to be a partner of Liverani, a leading Italian manufacturer, supplying us with highest-quality Flexible Impeller Pumps.

The S/P and MID ranges of Flexible Impeller Pumps, are designed to deliver pulsation-free pumping for the Agricultural and Transportation industries. The S/P range connects via PTO or coupling and is available in 4 sizes, while the MID Hydraulically Driven range suits hydraulic motors or couplings and is available in 3 different sizes.

With the flexibility to rotate the pump head into 5 different positions and a variety of impeller material options, these pumps can also deliver optimal performance in the Hygienic sectors.

Typical applications for our S/P & MID Flexible Impeller Pumps:

Download Brochure

Bareshaft S/P Range

The Bareshaft S/P Series of Flexible Impeller Pumps come in 4 sizes (MINI, MINOR, MAJOR and MAXI).

The series can be connected with a PTO drive or assembled onto an existing motor and baseplate via a coupling.

MID Hydraulically Driven Range

The MID Series is available in 3 different sizes: MINOR, MAJOR and MAXI.

These Flexible Impeller Pumps can be fitted with Orbital Hydraulic Motors (50 CC) or with coupling suitable for attachment to an existing hydraulic drive system. – and manual and spring-loaded by-passes are available on request.

In general, Self-Priming Flexible Impeller Pumps are often used for applications where the process media is delicate, shear-sensitive or viscous with solids in suspension.

The Bareshaft and Hydraulically Driven Flexible Impeller Pump Series are useful when an existing drive train is already in place, such as: PTOs, belt drives or hydraulic motors on vehicles such as trucks, tractors and boats.

They are the perfect solution for low head transfer, filling, metering, loading and offloading applications in both industrial and hygienic sectors for a variety of reasons, including:

Bareshaft S/P Range

The Bareshaft S/P Series of Flexible Impeller Pumps come in 4 sizes (MINI, MINOR, MAJOR and MAXI).

The series can be connected with a PTO drive or assembled onto an existing motor and baseplate via a coupling.

MID Hydraulically Driven Range

The MID Series is available in 3 different sizes: MINOR, MAJOR and MAXI.

These Flexible Impeller Pumps can be fitted with Orbital Hydraulic Motors (50 CC) or with coupling suitable for attachment to an existing hydraulic drive system. – and manual and spring-loaded by-passes are available on request.

In general, Self-Priming Flexible Impeller Pumps are often used for applications where the process media is delicate, shear-sensitive or viscous with solids in suspension.

The Bareshaft and Hydraulically Driven Flexible Impeller Pump Series are useful when an existing drive train is already in place, such as: PTOs, belt drives or hydraulic motors on vehicles such as trucks, tractors and boats.

They are the perfect solution for low head transfer, filling, metering, loading and offloading applications in both industrial and hygienic sectors for a variety of reasons, including:

The Bare Shaft and Hydraulically Driven Flexible Impeller Pump has many benefits including:

| Max Flow (m³/hr) | 44m³/hr |

| Max Pressure (m) | 32m |

| Max Temperature (°C) | 100°C |

| Max Viscosity (cP) | Up to 50,000 cP |

| Outlet Sizes | ¾” up to 3” |