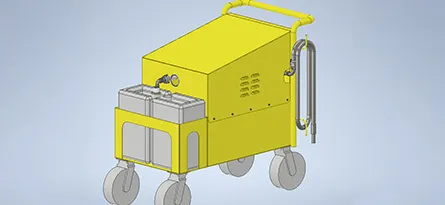

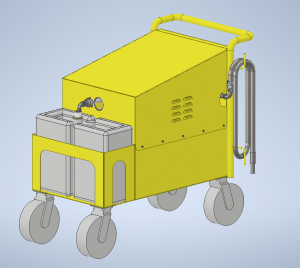

A client in the manufacturing industry for railways approached us in search of a bespoke solution to enable mobile pumping. Our team of expert engineers was pleased to support the project, designing a robust, transportable, battery-powered pumping system.

Application Details

The end-user is a manufacturer and supplier to the Railway Industry, and they were looking for a bespoke pump trolley suitable for the specific needs of the environment, that could empty 25L jerry cans, filled with a toilet cleaning product within 1 minute.

Tapflo UK’s team of expert engineers was happy to oblige and set to work straight away in designing a bespoke pumping system

Requirements for the Pump Trolley:

- This system needs to be mobile so can be transported wherever is needed

- The whole system to be robust and so can handle being pulled over different terrains and in weather conditions without breaking or falling apart

- The pump needed to be able to pump chemicals safely

- It needed to be battery powered as it was unable to be constantly connected to power whilst in use, but last enough time to be used to its full capacity

- A small monitor would be useful so operators could see the battery life of the system

- The solution needed to achieve 25L/min with a discharge of 3m.

Pump Trolley Solution

As a completely mobile solution was required, and the end product would potentially have to cross railway tracks, we could not have live electric lines running across the floor. Typically, with a Tapflo-designed mobile solution, the wires to power the pump would run from the unit along the floor to the power point; however, this was not an option with this solution.

The complete system was designed in-house by Tapflo UK’s Technical Engineering Team and was bespoke to the client’s requirements.

Our team designed and fabricated a robust trolley system that was battery-powered, completely mobile and power-independent. The battery was required to be charged from 110v AC electrics, standard for the Railway Industry.

The battery is 17AH rated and provides 1 hour of operation before needing to be charged. To limit dependency on electrics and reduce the footprint of the trolley, we used a 24v DC Pump and battery/buffer module to ensure the high amperage pull of the motor during start-up was well accounted for.

The Battery Monitor is fitted to the front of the trolley, underneath an ergonomically designed push bar, to display the battery percentage and health.

The wheels are puncture-proof and large in both diameter and width (ø260 x 85 mm), with front 2x swivels and rear 2x brake swivels.

The trolley features a removable cover to protect against environmental weather conditions and potential accidental damage from operators, and internal electrics have been sealed into their own control panel for added protection.

The externals were painted Sun Yellow to comply with railway industry standards, with a signal black push bar to contrast.

Features & Benefits of the Pump Trolley

The Pump Trolley delivered many benefits to the end-user, some of which include:

- A Flexible Impeller Pump due to self-priming capabilities, as well as an extremely robust design and chemical resilience.

- The battery on the unit allows ~60 toilets to be serviced on one charge

- Protected against environmental factors e.g weather, pollution, spills, terrain,

- Compact with a small footprint for easy manoeuvrability through doors

- A discharge hose wrap support for easy storage when not in use

- Room for 2x 25L jerry can storage on the front of the trolley for easy transfer through the attached pump, and a skeletal frame for jerry cans to allow easy run-off/drainage in case of spillage.

- Ergonomic design with push bar allows easy manoeuvrability by the operator.

- Stainless steel trolley frame had rolled edges as additional safety for operators.

Results

The client was more than impressed with the bespoke system that Tapflo UK created, this system was designed to each specification and no details were spared. The trolley is fully transportable to wherever needed and can effectively decant the jerry cans of fluid to where needed.

If you’re looking for a complete solution, our team of Technical Engineers are available to design and build a unit that meets all your requirements. Contact the team today to get started on a bespoke solution for your industry requirements. Alternatively, check out our range of other case studies for more pump solutions we have provided to clients over the year!