Marine applications face many challenges due to the harsh and demanding environment. These challenges range from complex fluids (produced water containing gas and traces of oil), corrosive vapours and limited access to maintenance. The client had previously been struggling with repeated equipment failures, simply because it could not keep up with the challenging applications.

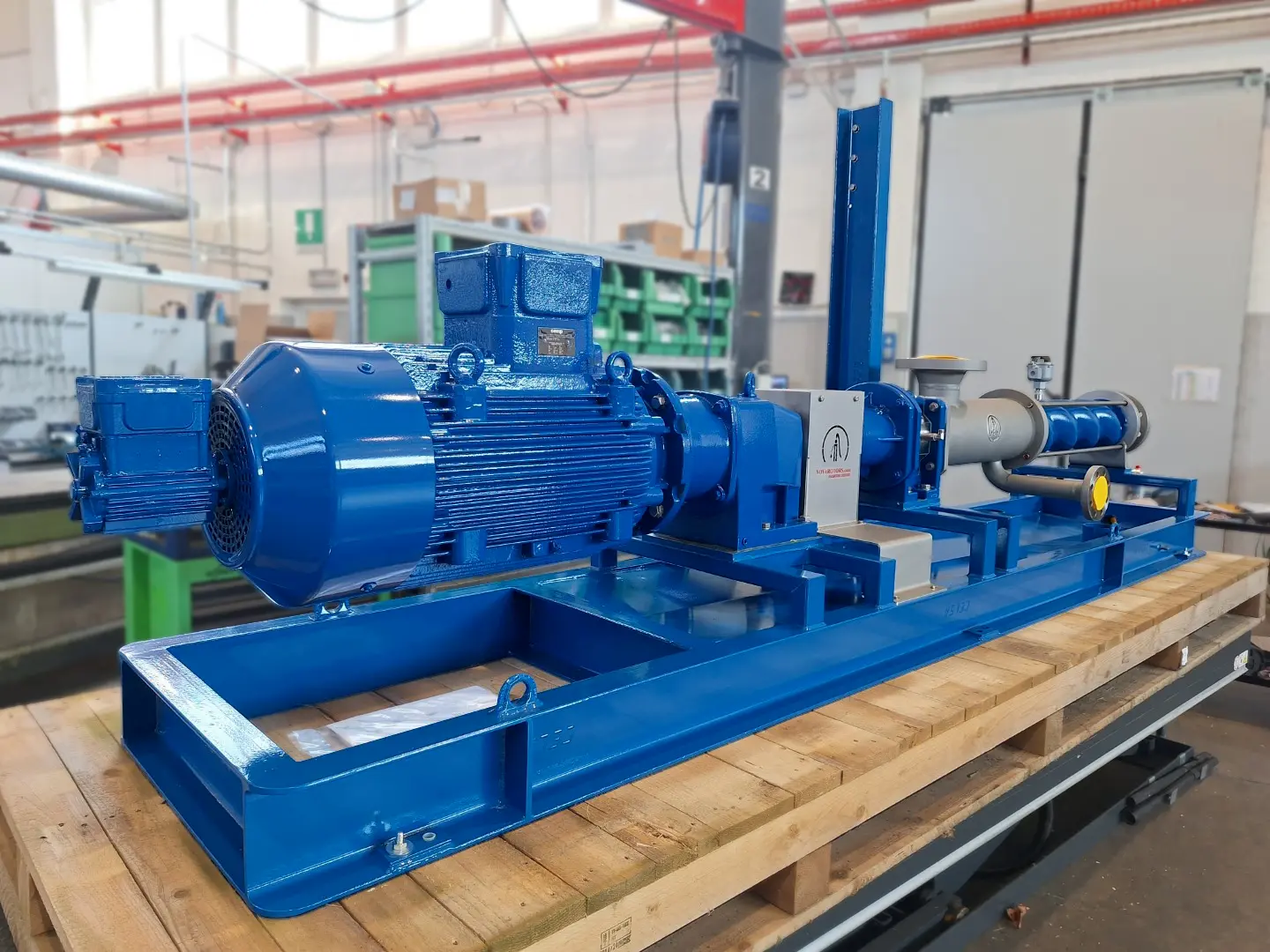

Our Engineering Team developed a JN40K2EL Industrial Nova Rotors Progressive Cavity pump, fully customised for a marine environment with longevity in mind, using the utmost protection and highest quality materials to avoid downtime. Ultimately, reducing the overall cost of ownership and the 30 years the pump will be operational.

Background & The Challenge

The client initially used a screw pump that was installed in 1993. In 2015, the site was upgraded to Waukesha 320-UW Lobe Pumps. However, during the handling of Produced Water (containing minor amounts of entrained gas, fine particulates and trace levels of crude oil and other chemicals), the Lobe Pumps experienced excessive vibration along with other issues. This resulted in premature pump failures and cracked downstream pipework.

Application Details

Our expert engineering team stepped in to assess the situation and develop a more robust, reliable solution — one that could handle the demands of the fluid and stand up to the harsh offshore environment.

The team provided the client with a pump unit and monitored its performance over the following 12 months to ensure the selected model was appropriate and operating optimally for the application.

Original Pump Key Specifications

- Unpressurised Single Cartridge Mechanical Seal – APPI682, SiC/SiC/FPM

- Custom Inlet outlet Flanges to best suit existing pipework

- Pump with drain ports

- FPMG Stator, Even Wall with Tapped hole for probe (PT100)

- Hard Chrome Plated 850-950 HV SP 300 um Rotor

- CF8M Construction

- ATEX 2014/34/EU II 2G Ex h IIB Gb TX Compliant

- Dry Run Protection

- Carbon Steel Standard Baseplate

- Non-Pressurised Flushing Kit with 3l st/st tank

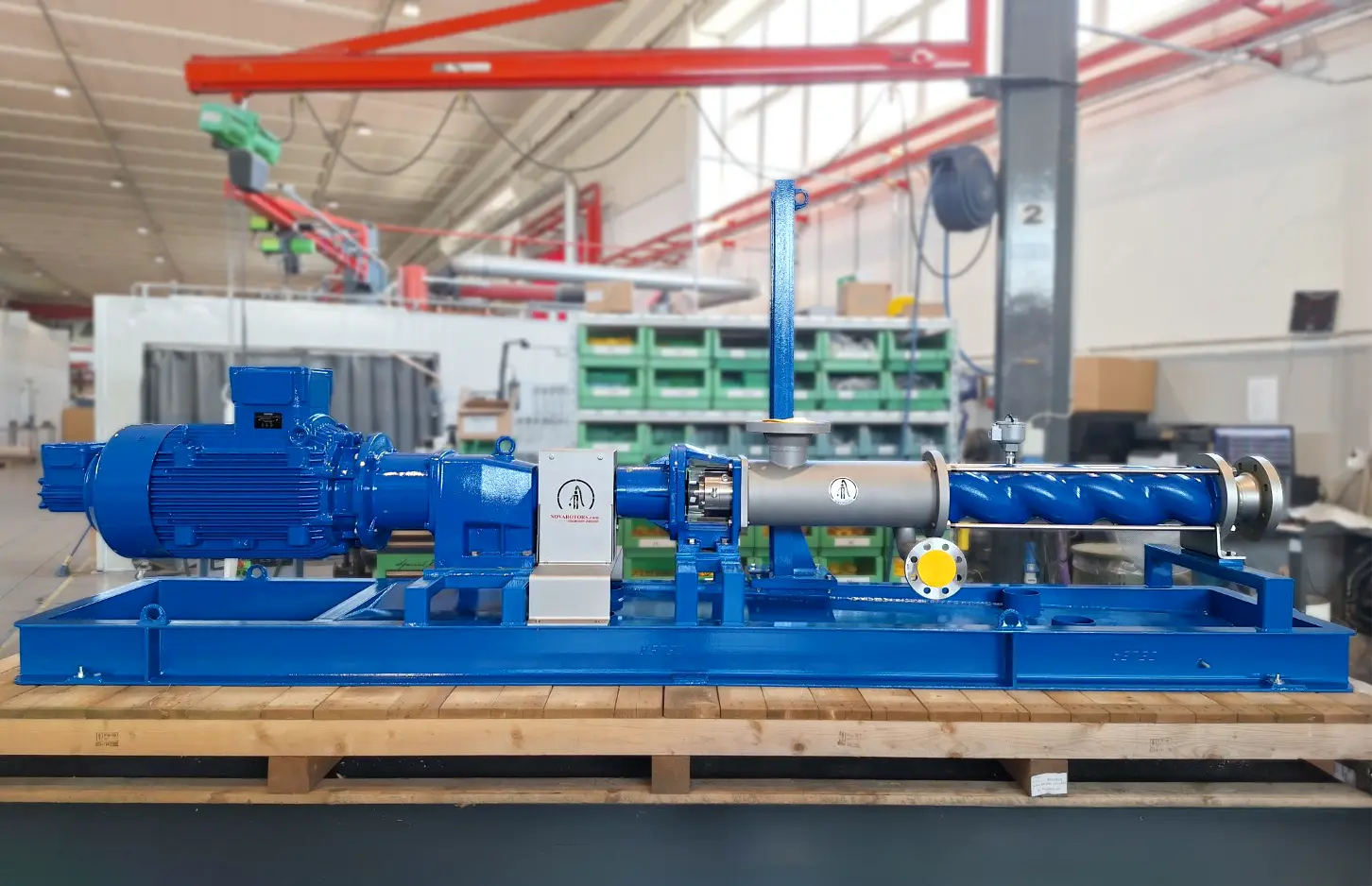

After a carefully monitored 12-month trial period, our team upgraded the pump unit with a more advanced sealing system that is more durable and offers better protection. The new pump unit has the following key changes:

- Pressurised Double Cartridge Mechanical Seal – API682, SiC/SiC/FPM – SiC/SiC/FPM

- Plan 53A Flush Kit

- Carbon Steel API 676 Baseplate

- IP56 Motor

Impact & Results

The custom Nova Rotors Progressive Cavity Pump unit delivered significant benefits, addressing our client’s needs for improved efficiency, reliability and longevity. To ensure this, our pumps came equipped with full testing, material certifications and documentation. The upgraded Pump unit was specifically designed to withstand the harsh offshore environment and reduce the need for frequent maintenance.

The core benefit of the pump unit is that it’s built with dry-run protection, which instantly cuts the pump off upon no media being present at the inlet. This not only provides the best longevity from the installation but also provides a degree of automation. By preventing the pump from running dry, the system allows the operator to perform different tasks with confidence. Therefore, reducing costs, decreasing downtime and increasing ease of use.

Some other key benefits include:

- Plan53A Mechanical Seal: Provides the best possible longevity for the Mechanical Seal by ensuring it’s cool, lubricated and minimising friction.

- ATEX Compliant: Provides a reliable solution given the lack of maintenance options available out in the middle of the sea.

Once the new pump is installed, the second pump will be returned and overhauled to bring it in line with the second pump, allowing the client to keep a complete spare unit on-site. The upgrade works provides a more cost-effective solution for a backup pump and ensures that the original unit is still put to good use.

Whether it’s offshore, ATEX-rated, or handling complex fluids – our team is ready to engineer a pump solution tailored to your needs. Get in touch with the team today!