A leading Chemical Manufacturer operating a 24/7 production line was facing serious containment issues with their existing pump setup. The client handled highly corrosive chemicals, and any failure in containment posed significant health, environmental, and compliance risks.

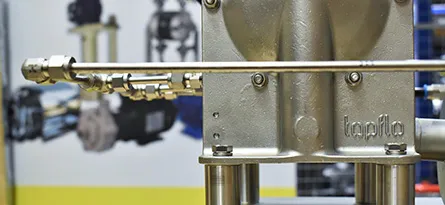

They initially selected a standard Tapflo Diaphragm Pump for cost-efficiency, but over time, the application demanded a more resilient solution. This is where Tapflo suggested a Barrier Pump for a more effective and resilient operation.

The Challenge: Frequent Diaphragm Failures Leading to Risk & Cost

After several months in service under exceptionally demanding operating conditions, the standard Diaphragm Pumps originally supplied began experiencing diaphragm fatigue. This particular application pushed the pumps far beyond typical operational parameters, leading to leaked fluids contaminating the compressed air system and the surrounding environment, causing:

- Risk of chemical exposure to operators

- Disruption to production due to unscheduled maintenance

- Additional costs owing to downtime and maintenance procedures

- Continuous material loss during leaks

- Potential failure to meet internal HSE standards

“The pumps were operating around the clock, so even small leaks compounded into significant safety concerns and product loss,” – Tapflo End User

The Solution: Barrier Diaphragm Pump with Guardian System

Tapflo UK recommended an engineered upgrade – our Barrier Diaphragm Pumps with integrated Guardian Systems.

Key Components of the Barrier Pump:

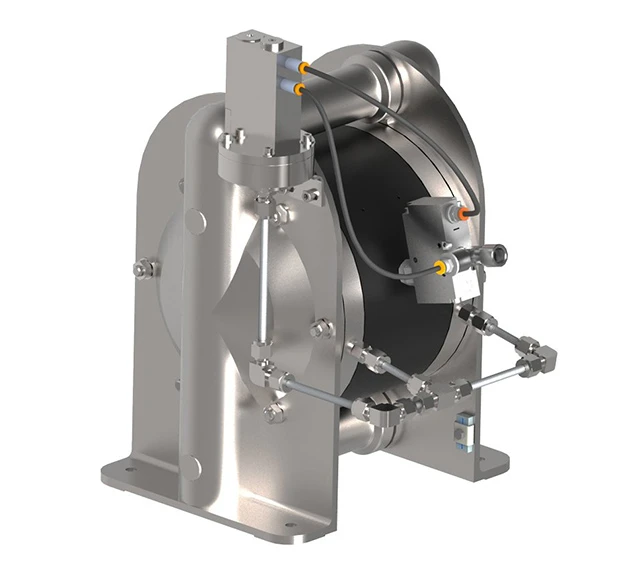

TX220 STT Barrier Diaphragm Pump:

The dual-diaphragm design internally traps leaked fluid if a rupture occurs, providing an additional layer of protection that significantly reduces downtime, lowers operational costs, and ultimately extends the overall longevity of the installation in such demanding applications, all without interrupting flow.

- Designed and configured in-house by Tapflo UK

- Detects rupture in real-time

- Automatically shuts off the pump

- Signals a secondary pump to start

- Notifies operators of the failure

Pre-Configured & Factory-Tested Setup:

- Pumps were supplied ready to install. No reconfiguration of pipework or compressed air supply was needed due to shared porting with the original pumps.

Results & Measurable Benefits

The client benefited hugely from the new pump; these benefits included:

- Zero leaks since the upgrade

- Fully automated switchover for continuous uptime

- Reduced operator involvement, enhancing site safety

- Faster maintenance turnaround due to modular pump design

The results of the before and after speak for themselves:

| Metric | Before | After Implementation |

| Leak Incidents per Month | 2–3 | 0 |

| Chemical Loss (Est. p/m) | ~£3,000 | £0 |

| Safety Interventions/Shutdowns | Multiple | None since deployment |

| Maintenance Time (avg/month) | 6–8 hours | <1 hour for inspection only |

| Cost of Spares (for diaphragm failures) | ~£500 p/m, £6,000 annually | 2x liquid kits p/a = £1,000 annually |

Proven Containment and Control for High-Risk Applications

This highlights how Tapflo UK not only provides high-performance equipment but also acts as a consultative partner in process safety and systems integration. For applications involving aggressive chemicals, containment failure is not an option. Our Barrier Diaphragm Pump with Guardian System monitoring delivers a reliable, smart, and cost-effective upgrade path for your production line.

Facing Similar Challenges?

If your facility is handling hazardous or high-value media, don’t wait for failure; contact us to secure a more robust pumping system like we did with this client. Contact our technical team to evaluate your current setup and explore advanced containment options with Tapflo UK’s engineered pumping systems.

Call us today to protect your people, product, and process.