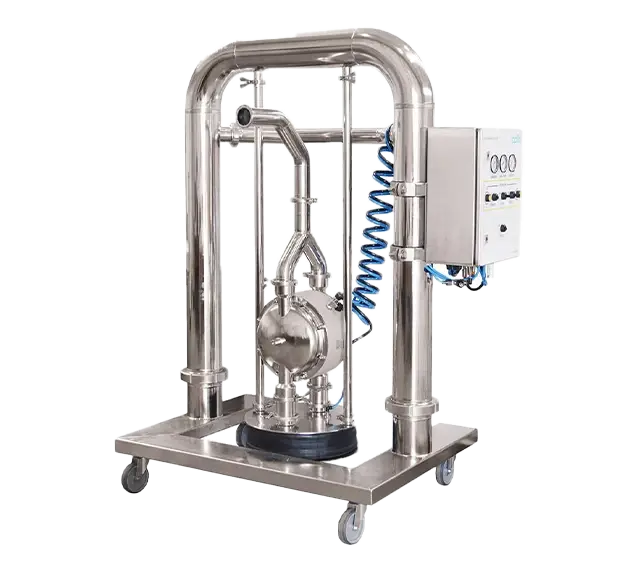

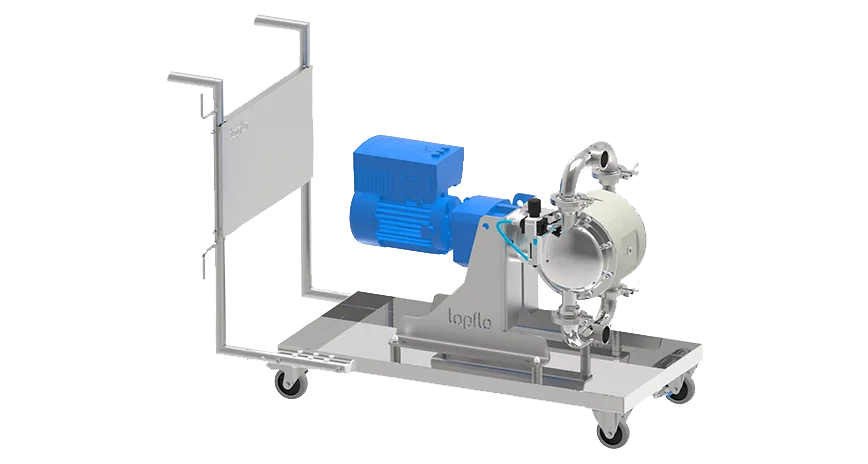

What makes our Diaphragm Pump Guardian System different?

The Air Operated Diaphragm Guardian System monitors fluid pressure, changing its output if the monitored pressure rises above or falls below the set point of the Guardian (dependant on configuration), controlling the associated pump according to the following applications:

- Dry Run & Stop

- Deadhead & Stop

- Deadhead & Restart

- Dry Run & Deadhead

- Barrier Pump Monitoring & Control

Each application, as stated above, is available by fitting a Tapflo Guardian to your pump. This is available before delivery to your site as a preassembled and preprogrammed system. Alternatively, you can fit this yourself on site.

Please be aware there are additional parts involved in creating these Diaphragm Pump Control Systems. Speak to the Sales Team to discuss the required parts.

Dry Run & Stop

The Air Operated Diaphragm Guardian System monitors the fluid discharge pressure of the pump, stopping it if the pressure falls below the setpoint, caused by a lack of media on the suction causing air to be ingested into the pump. (PDRN System)

Benefits:

- Extend the life of your pump’s diaphragms

- Reduced consumption of compressed air

Deadhead & Stop

The Air Operated Diaphragm Guardian System monitors the fluid discharge pressure of the pump, stopping it if the pressure rises to the setpoint, caused by a closed valve or overpressure in the discharge line. (PDHS System)

Benefits:

- Increased life of the pump’s diaphragms

- Safe & reliable operation

- Consumption of compressed air can be reduced

Deadhead & Restart

The Air Operated Diaphragm Guardian System monitors the fluid discharge pressure of the pump, stopping it if the pressure rises to the setpoint, caused by a closed valve or overpressure in the discharge line. When the pressure falls below the set pressure, the pump automatically restarts. (PDHR System)

Benefits:

- Increased life of the pump’s diaphragms

- Safe & reliable operation

- Consumption of compressed air can be reduced

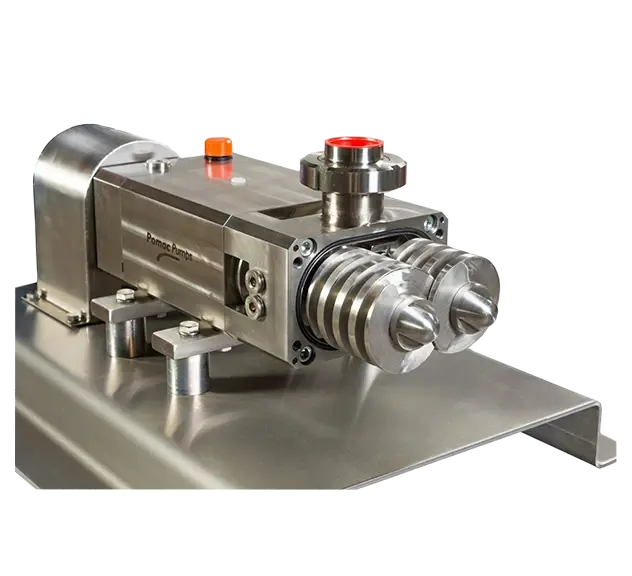

Dry Run & Deadhead

The Electronic Dry Run & Dead Head Protection System guarantees reliable, effective and safe operation of your pump whilst reducing the consumption of compressed air, meaning lower operating costs!

Pump switch-off thresholds can be set up to 0.05 bar, allowing incredibly accurate setting and protection parameters. (EDRH System)

Benefits of using the EDRH Protection System:

- Reduces the consumption of both compressed air and electricity by turning the pump off in case of inefficient operation

- Elongates the lifetime of the pump’s internals, such as diaphragms

- Turns off the pump in case of the accomplished task, such as unloading tanks

- Limits the discharge pressure of the pump

- It gives a real-time indication of the pressure values

Main features of the EDRH Protection Device:

- Wetted parts of the system in contact with the fluid are made from AISI 316L

- Intuitive operation by use of only three buttons

- The precise configuration of the pump on/off parameters up to 0.05 Bar

Barrier Pump Monitoring & Control

Barrier pumps (TB) have additional diaphragms used to back up the primary diaphragms. In case of a breach, the liquid remains inside the pump instead of leaking out through the air exhaust. The Guardian monitors the pressure between the primary and secondary diaphragms, stopping the pump if the pressure increases above the set point. (PDFM System)

This system is to be used in conjunction with the Diaphragm Alarm System, which will immediately alarm and shut off the pump at an eventual diaphragm break. It ensures that no liquid will leak into the environment or to the air system of the pump – a perfect system where you require a high level of safety.

How the Barrier Pump monitoring & control system works:

The system consists of a backup diaphragm pump (TB) and a control and alarm system. Under regular operation, the chamber between the backup diaphragm and the wetted diaphragm is set to vacuum by the control system. If any diaphragms break, the pressure will rise in the vacuum chamber. The control system will then switch off the pump and turn on the horn. This system is allowed for use also in explosion hazardous areas since only pneumatic components are used.

The panel is 200 x 200 x 130 mm and is available for all Tapflo AODD pumps from 2” and up and can be supplied in either ABS Plastic (IP55 or 65) and Stainless Steel AISI 316 (IP44).