A major UK sandwich filling manufacturer, producing over 250,000 units per week, needed to overhaul its mayonnaise batching process to keep up with production demand and improve hygiene, accuracy and profitability.

With expertise in hygienic pumping, custom control systems, and cross-zone process engineering, the client approached Tapflo UK to deliver a turnkey solution tailored to the site’s unique operational needs.

Application Details - The Client's Challenge

The clients’ existing method relied on manual transfer of 5kg sachets of mayonnaise from a Lo-Care storage room to the Hi-Care production area, where operators would cut open and squeeze each sachet into 1 of 3 mixers.

While this process was labour-intensive and inefficient, it also made it difficult to maintain hygiene standards as no traceability or batch data was available for quality control.

Our clients’ existing approach proved to be labour-intensive, requiring at least 2 operators per shift. Additionally, they were faced with:

- High Ingredient Costs: Purchasing mayonnaise in sachets costs significantly more than buying it in bulk

- No Traceability: No data on quantity used or when batches were made were available, affecting quality control requirements

- Production Bottlenecks: Slow batching processes created unnecessary delays

- Hygiene Risks: Sachet cutting and squeezing introduced significant contamination risks

- Limited Space: The system had to be split between Lo-Care and Hi-Care zones, and so the footprint was a consideration

System Components - Our Solution

Our Process Engineering Department designed and delivered a custom semi-automated mayonnaise pumping and batching system, allowing a single operator to accurately batch mayonnaise from bulk pallecons (1000L) directly to any of the 3 mixers, all from a central control panel in the Hi-Care zone.

The system was split across hygiene boundaries:

- Lo-Care: House the pumps and pallecons

- Hi-Care: Installed the control panel and delivery pipework to the mixers

System Equipment Supplied:

- 3 x Tapflo TC425 STS-11SFRMV Sanitary Air Operated Double Diaphragm Pumps

- Hygienic baseplates, isolation valves, and pressure sensors

- 1 x Custom PLC/HMI-based control system

- 6 x Food-grade hose assemblies

- 3 x Stainless Steel pipe runs with rotatable 90° delivery spouts

Key Capabilities of the System

The bespoke system enabled the facility to automate their system, adhering to all their needs and providing these benefits:

- Precision batching (±5kg accuracy)

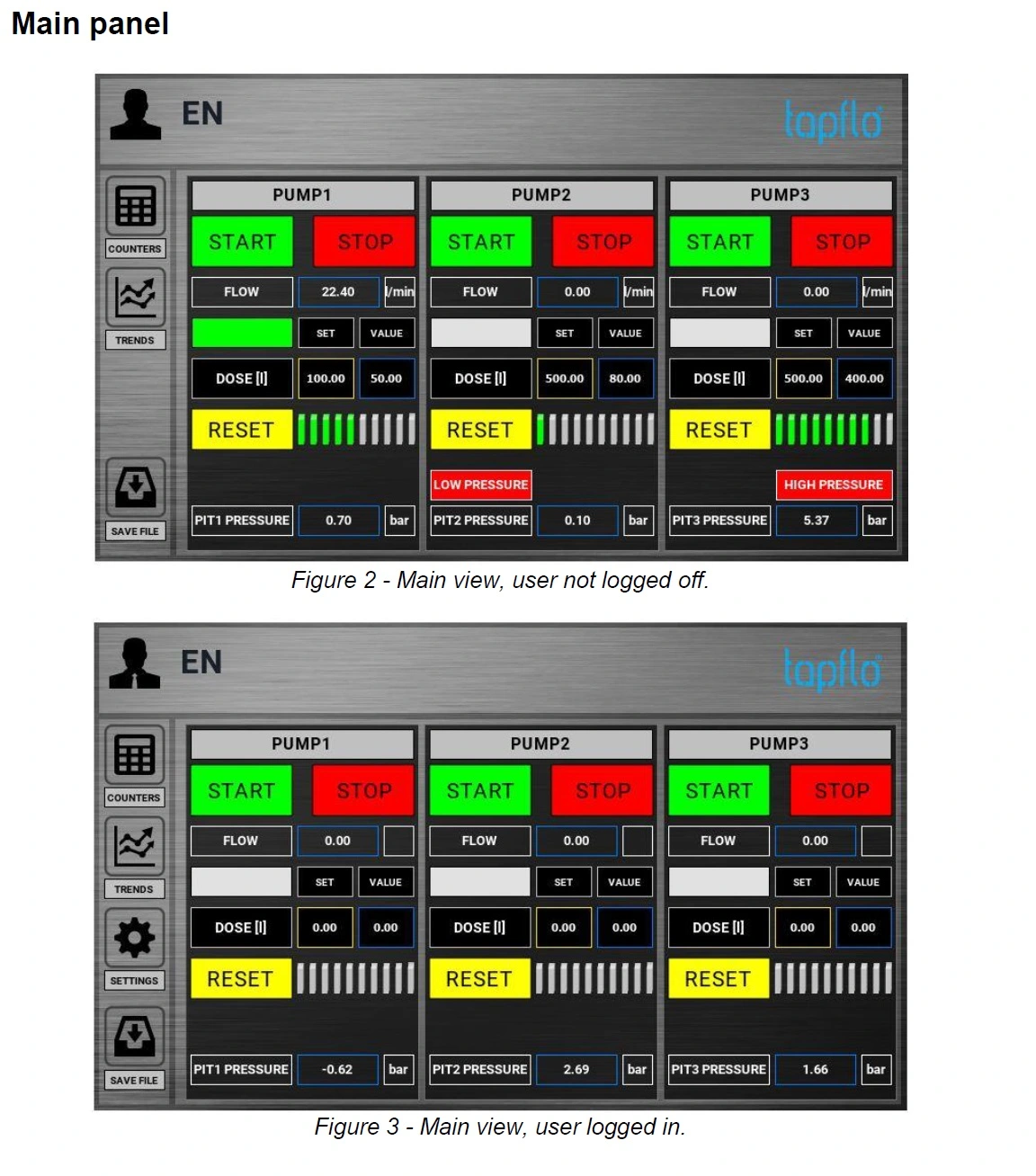

- Touchscreen HMI with recipe input per mixer

- Full data logging for traceability

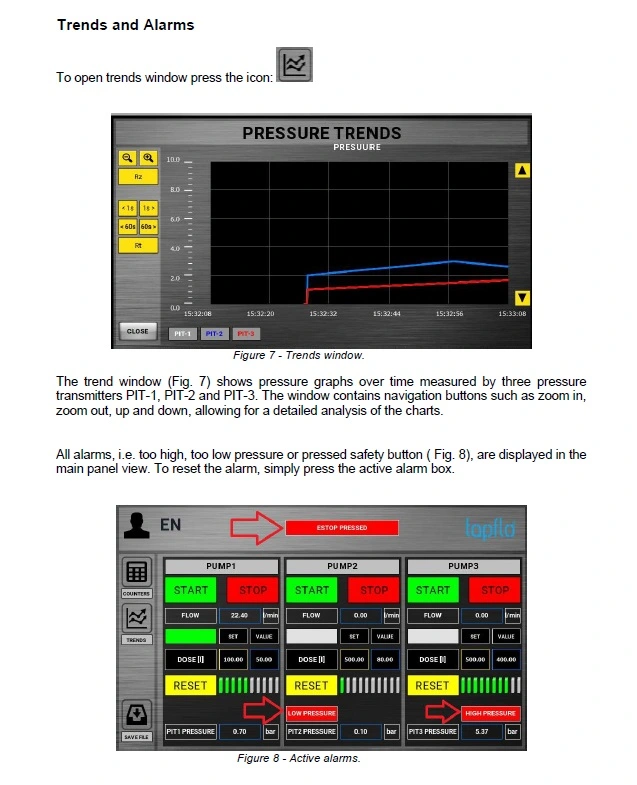

- Live monitoring of flow rate, pressure and batch status

- Auto-stop on empty pallecon or dry run

- Pause/resume feature mid-batch

- Maintenance tracking such as run hours, stroke count etc.

- Power loss memory retention

- IP66 hygienic enclosure

- Food-grade pumps, pipework and components

Take a look below for the screen imagery to support training, traceability, and QA.

Installation & Support Services Included

Tapflo supported not only with installation but also with control, implementing safe design and on-site training of the system.

- Mechanical Installation: Lo-Care to Hi-Care bulkhead penetrations and mixer connections

- Enhanced Control: Electrical and pneumatic setup of pumps and panel

- Safety & Design: Full commissioning and testing

- On-Site Training: For operational and maintenance best practices

Hygienic Design in Action

One of the critical requirements of this system was the ease of cleaning in line with Hi-Care zone hygiene protocols. Tapflo UK provided two cleaning methodologies, giving the client operational flexibility depending on staffing and available downtime:

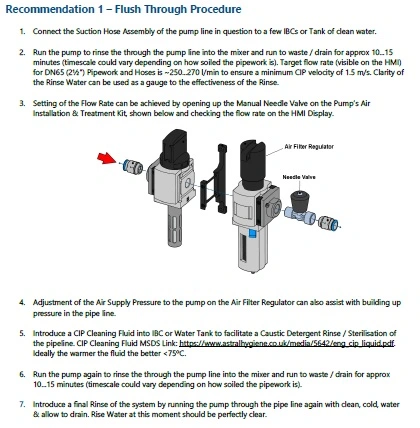

CIP Flush-Through (Preferred)

- Clean water rinse at 1.5 m/s line velocity

- Caustic detergent flush (≤75°C)

- Final clear-water rinse

- Controlled via HMI for visibility and validation

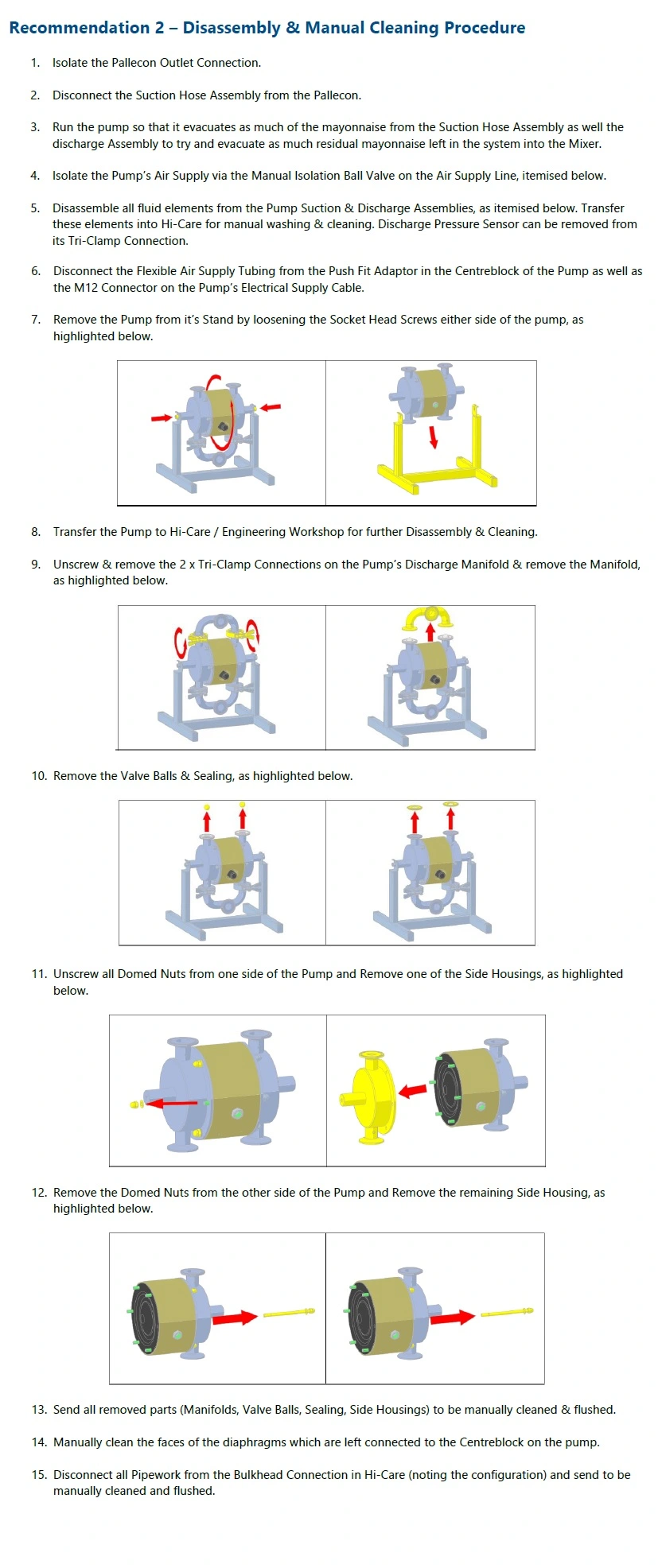

Manual Disassembly (Optional)

- Step-by-step illustrated procedure

- Full disassembly of pump and pipework for deep clean

- Designed for ease of handling in Hi-Care

The illustrated SOPs (standard operating procedures) below were provided as part of the training pack.

Results & Impact of the System

Alongside the benefits of the system, the client’s production was positively impacted and they discovered these results:

Operator Efficiency: Reduced the need from having 2+ operators to 1 only per shift

- Faster Batching: Eliminated sachet bottlenecks caused by manual handling of the sachets

- Cost Savings: Bulk mayonnaise = lower per-unit cost

- Full Traceability: Every batch logged by volume, date, time, and mixer

- Improved Hygiene: Closed system with sanitisation options

- Higher Uptime: Maintenance insights and Clean in Place design

“The new system has transformed the way we work – faster, cleaner, and more accurate. We’re now saving on both labour and ingredient costs, while gaining the traceability we never had before.” – Site Manager, Food Production Client

Ready to transform your fluid handling process?

Whether you’re looking to improve process control or integrate smart system automation, our team is ready to help you design a solution that fits your operational requirements.

Get in touch with Tapflo UK today, and our engineers will be happy to discuss your process challenges.