Utilising Hygienic Lobe Pumps in Food Manufacturing

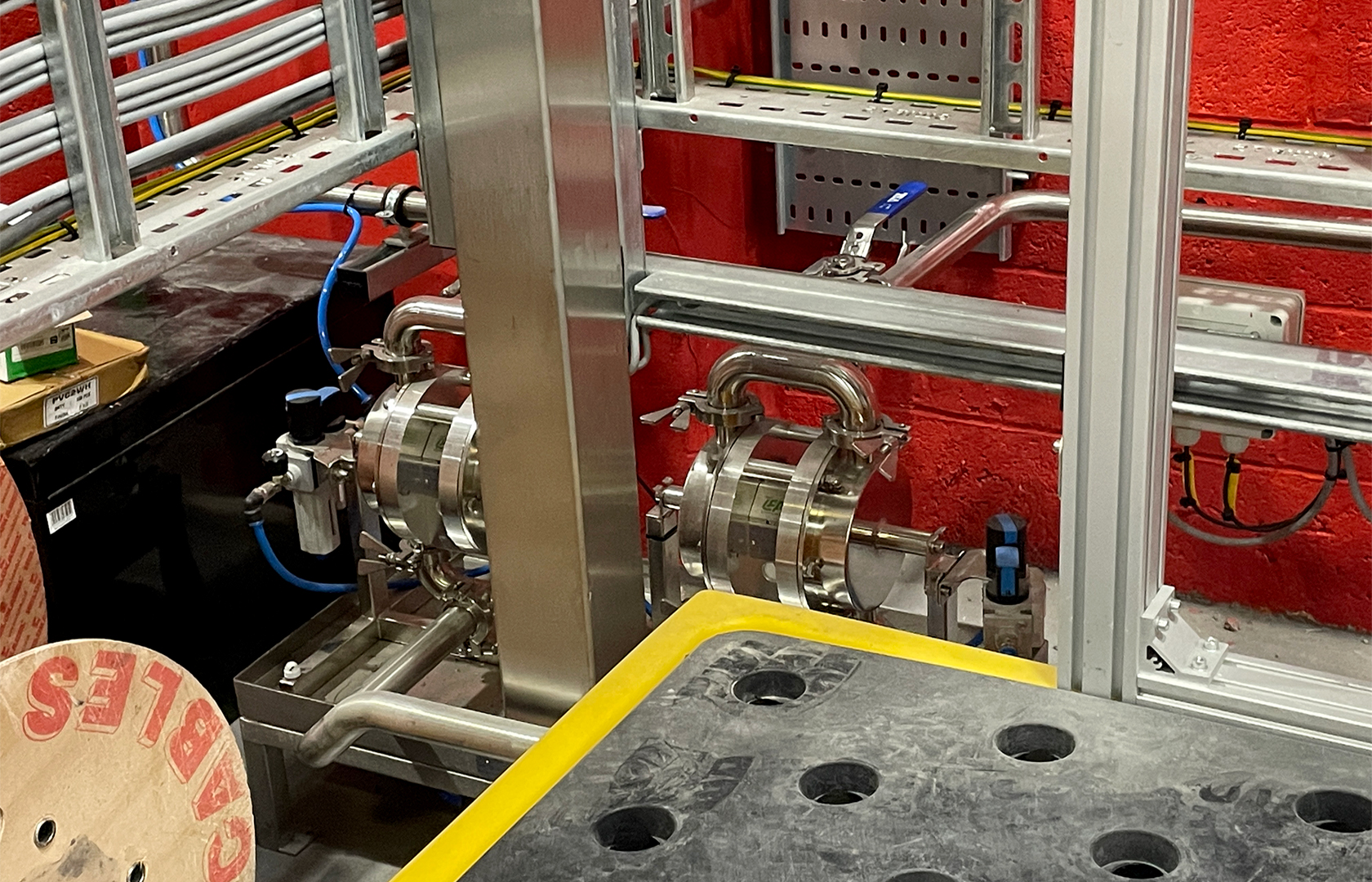

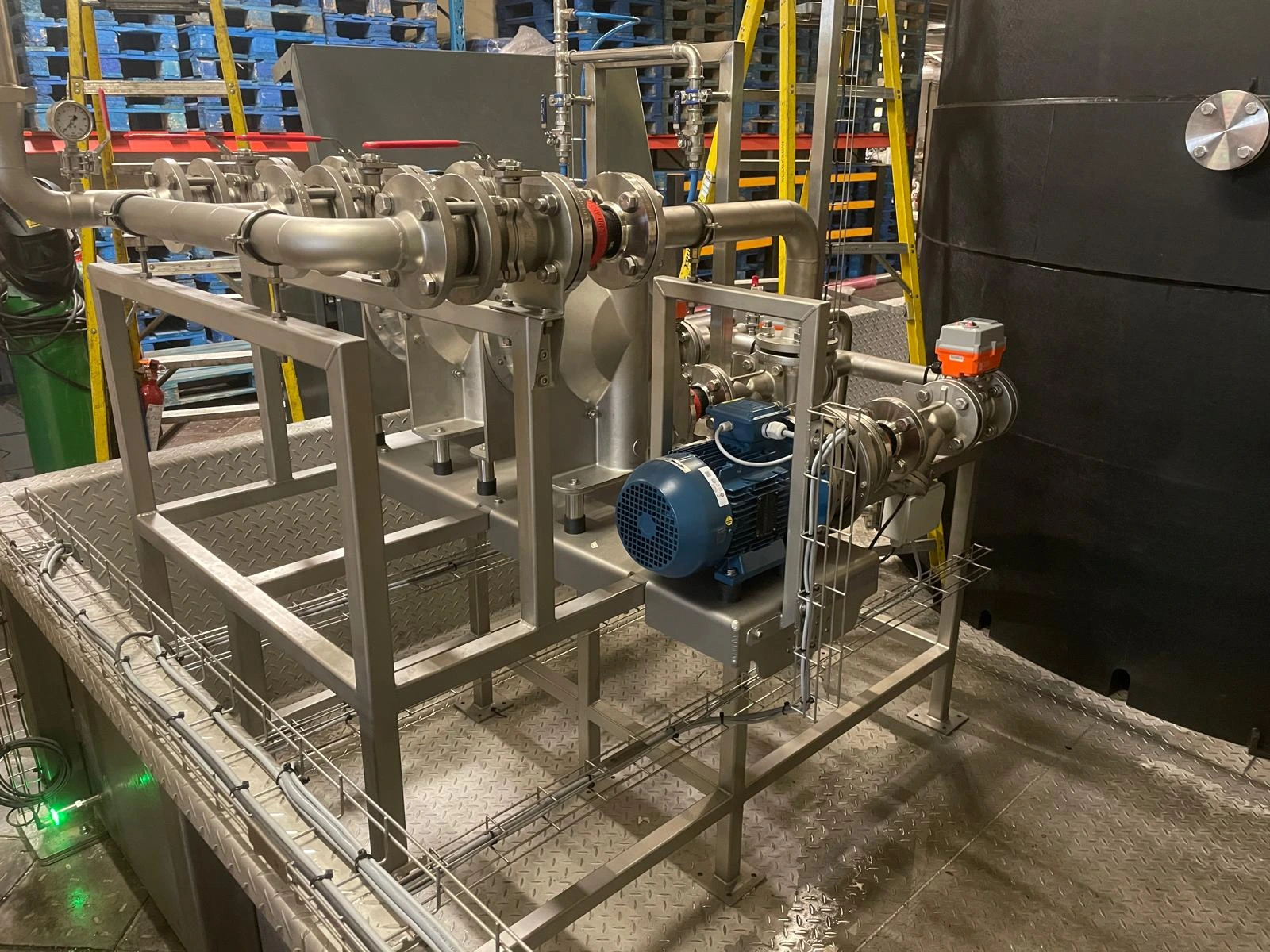

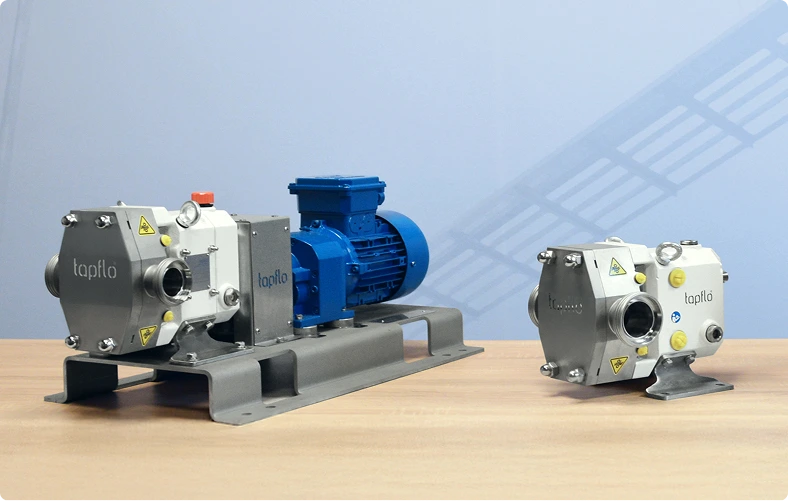

A food manufacturer reached out to Tapflo UK in search of pumps that could pump viscous fluids containing solids from IBCs into large ribbon mixers. Tapflo UK were able to help and supply 2x LPX50 & 2 x LPX80 units with flow meters and batch control panels.