Application, Features & Benefits

Application Examples

- Cream, Custard, Baby food, Yoghurt Drinks

- Bleach, Soap, Shampoo

- Mayonnaise, Ketchup, Mustard

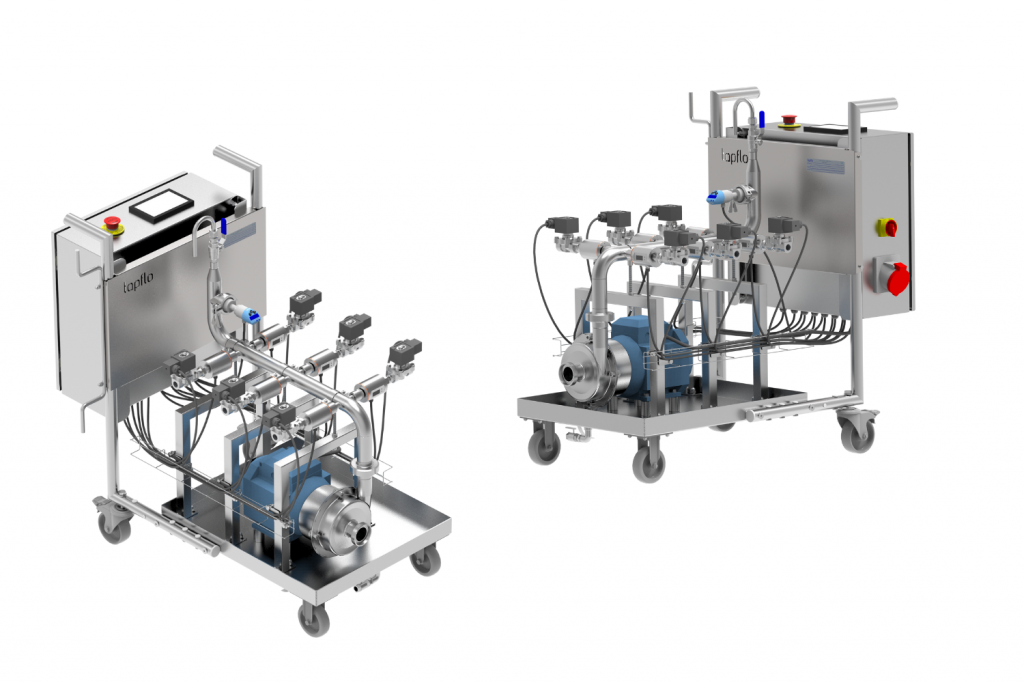

Features

- Stainless Steel Construction

- Drip tray and valve included

- Ultra-precision filling

- Accurate control with inbuilt PLC controller programming

- Suitable for a wide variety of applications

- All in one portable solution

Operation Principle

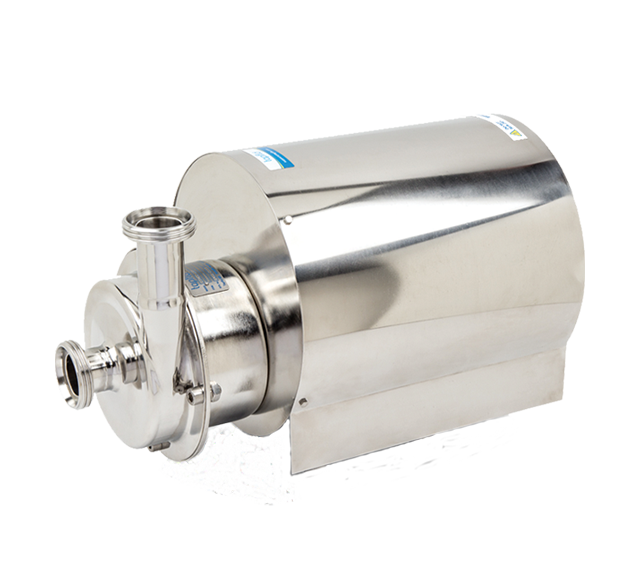

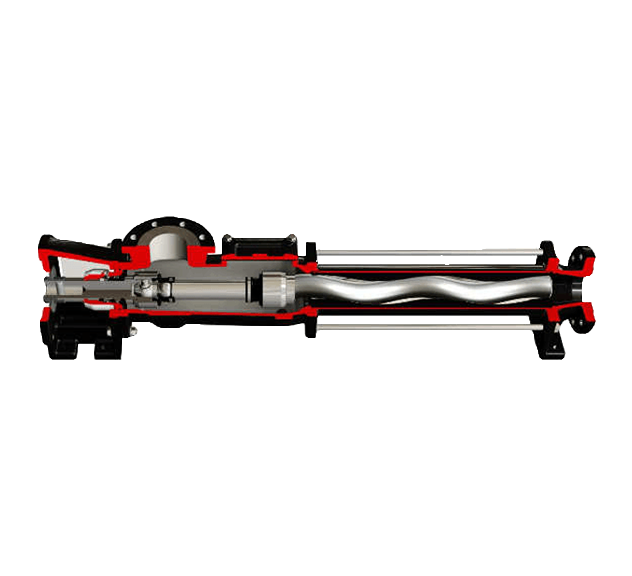

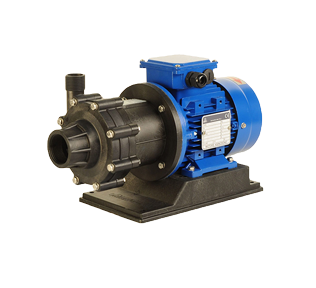

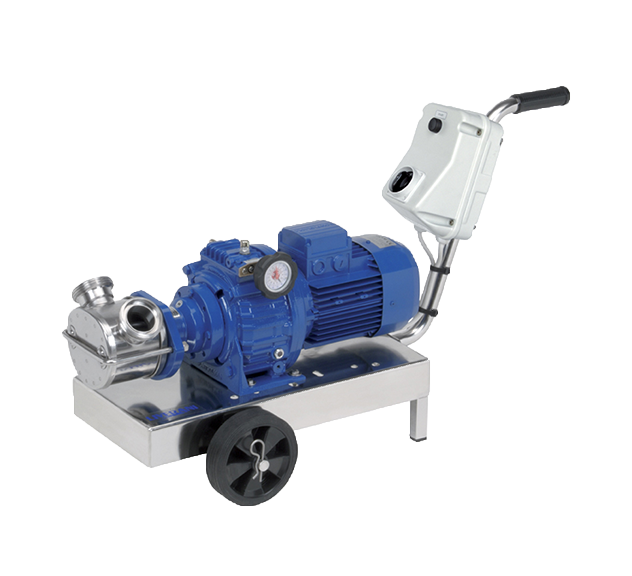

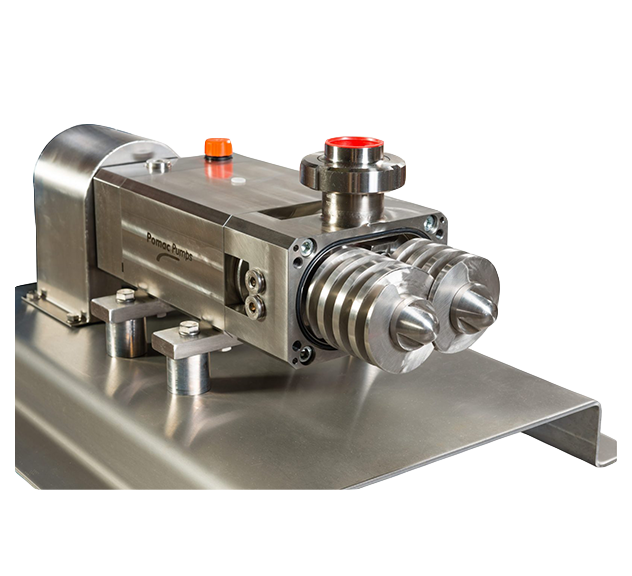

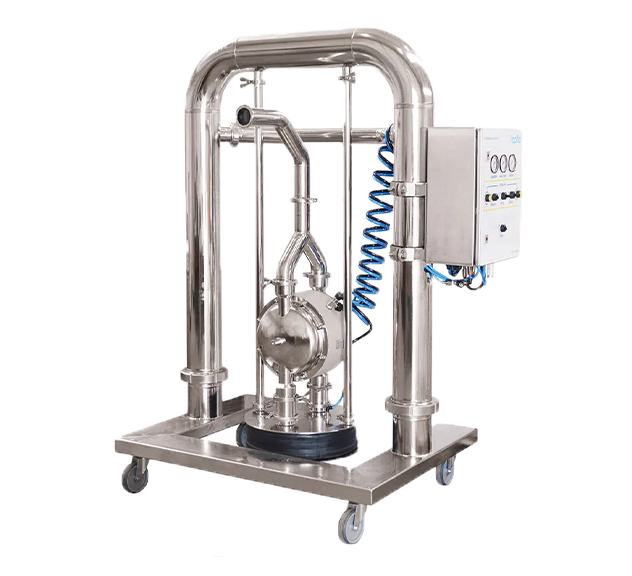

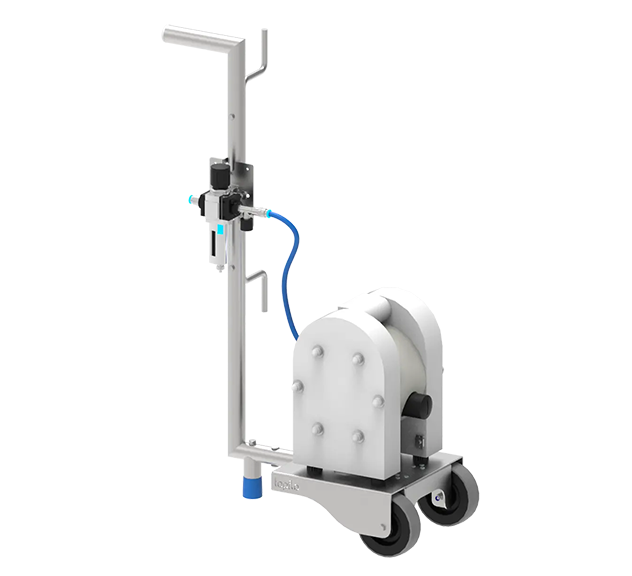

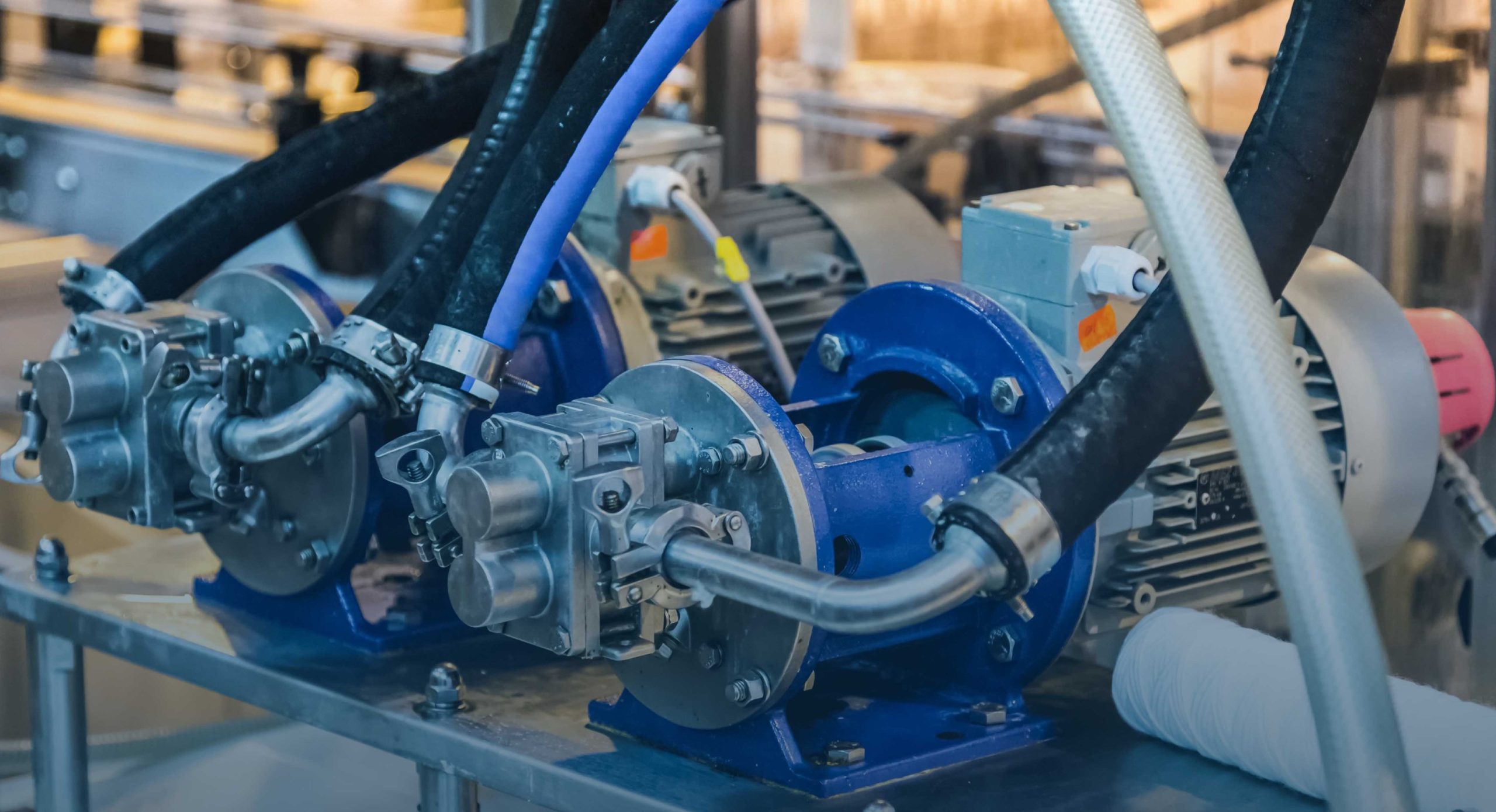

The operation of the bottle filling machine system is based on a Centrifugal Pump, flowmeters, discharge shut-off valves and a dedicated control system. As standard, the system is suitable for products with a viscosity up to 1000 cP. However, we have supplied bespoke units for thicker products. By using the touchscreen at the control cabinet, the operator can select which outlets should be used for filling (it can be from 1 to 6 with single, multiple or all selected). Also, for each outlet, there can be set a volume of liquid to be transferred. Usually, it is the same volume for all outlets, but this can be easily changed if required.

It is also possible to create and save programs dedicated to specific liquids and bottle sizes. The pump transfers the liquid through the selected outlets, each built with a flowmeter and a shut-off valve. When a required volume at any given outlet is reached, the shut-off valve gets immediately closed, and the operation of the pump is stopped. The system is built using a soft starter to prevent splashing and bubbling of the product in bottles and pouches.

The system is built on a stainless-steel construction with a drip tray, and a drain valve included. The control cabinet is also made of stainless steel; it is mounted on the construction handles. There is included a frequency inverter, PLC controller with a dedicated program and a touchscreen, ON/OFF switch and E-STOP pushbutton.