A leading French company in the Energy-from-Waste industry approached Tapflo UK to assist with designing, building and commissioning a custom pump solution for an EfW site for the end-user.

Application Overview

The EfW (energy-from-waste) site produces Municipal Solid Waste (MSW) Incineration Bottom Ash (IBA). This IBA is stored in a bunker before being loaded into lorries and disposed of off-site. The IBA is a non-combustible residue of the MSW and contains approximately 20-25% moisture when it enters the storage. This moisture leaches from the piles and accumulates at the bottom of the bunker.

The client was looking for a pump solution to transfer the IBA sludge into waste gullies, where it can then be treated.

There was no access to the bottom of the bunker, so the sludge/slurry had to be pumped from the ground floor, located 7 meters above.

- Fluid: IBA Liquid Sludge/Slurry

- Temperature: 0°C to +50°C

- pH: 8 to 14

- Suspended solid content: Very abrasive & high concentration (small stones, metal shrapnel etc)

- Flowrate: 12m³/hr

- Dry Suction Lift: <7 meters

Site Requirements

| Site Requirements | Precisions | Reason |

| Compressed Air | 180.1 l/min of 4Bar air, in accordance with norm ISO8573-1 class 4. | For the Vacuum Pump |

| Power Supplies | 415 VAC / 3PH + N + E / 50 Hz (32A) | To Power Panel |

| Earthing Point | Earthing stip (10mm2) to site earth point | Earth Panel |

Equipment & System Provided

The custom pump solution for the EfW site was designed, supplied, installed, & commissioned by the Tapflo UK Engineering Team. It was designed as a turn-key solution with controls adjacent to the pump, and ancillary equipment to remove the leachate safely and efficiently from the bunker, no matter the conditions!

3” Peristaltic Pump with 90° Geared reducer

A Peristaltic Pump was the best choice of technology for this EfW project due to its indefinite dry running capabilities, easy maintenance, dry suction capability (0.98Bar), large solids capability (Pass solids up to <25% of hose ID) and minimal fluid contact parts.

The PTX80 size was chosen to maximise large solids handling and suction capabilities whilst minimising footprint impact.

Other benefits of Tapflo Peristaltic Pumps are:

- Hoses are reinforced & multi-layered (Braided Polyamide), high-grade material, giving optimal chemical and mechanical resistance.

- Pumps have a ‘longer sweep’ stroking pattern over similar performance pumps, giving a higher hose life expectancy.

- A Better Shimming strategy decreases compression on the hose, resulting in a longer lifetime.

Capacitive Sensor

The hose rupture detection sensor sends a signal to the local control panel in the unfortunate event of a hose burst. This stops the pump automatically and sounds a local alarm (audible & visual) so operators can carry out maintenance.

Vacuum Assist Pump System

The Vacuum Pump aids in high-viscosity/high suction lift applications by creating a vacuum inside the pump casing, preventing the pump hose from collapsing on itself. The vacuum pulls the hose apart so that the cavity inside the hose can be filled with air, discharging it from the suction line.

Ultrasonic Flow Switch

An Ultrasonic Flow Switch was added to the suction line to detect when the flow has achieved a set point. Once this activates, it sends a signal to the local control panel, shutting a solenoid valve on the pneumatic line to the vacuum pump, preventing wasted air.

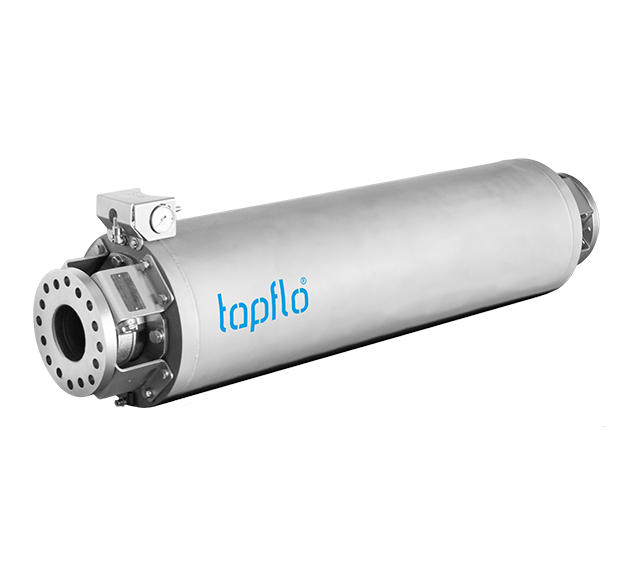

Pulsation Dampener

The pump discharge was fitted with an in-line pre-charged Pulsation Dampener. Because of the pump size, pulsation occurs in the discharge line. Although there is no flow monitoring equipment, Tapflo engineers installed the dampener to prevent the hose from moving due to pulsation and potentially hitting operators.

The DTP series in-line pre-charged pulsation dampeners are designed for the PT & PTL Tapflo Hose Pumps, and they utilise the same hose composition as the PT range (Polyamide Reinforced & Multi-layered). The DTP dampeners are pre-charged with compressed air and are set to two-thirds of the system pressure to achieve up to 90% pulsation reduction.

Flexible Hosing

The hoses were helically convoluted PTFE, ensuring optimal chemical resistance to the fluid, with an external vacuum wire due to the high suction conditions, and stainless steel on top for mechanical resistance to external impacts.

Actuated Butterfly Valve

Tapflo advised a cleaning protocol to prevent large sediment build-ups by inserting a manual pressure washer into the suction line once every quarter. To prevent the manual pressure washer from damaging the basket inside the strainer, a suitable Butterfly Valve was installed just before the strainer.

Single Basket Strainer with Differential Pressure Indicator

Because the bunker is located near the waste metals bunker, solids too big to process may find their way into the IBA bunker. Whilst the automated ash-collection claws above the bunker can detect and remove any large solid waste from accumulating inside the IBA Bunker, large stones or metal particulates may remain inside the bunker. A Basket Strainer fitted with ø15mm perforated mesh was installed on the suction line. The differential pressure indicator monitors strainer pressure and, when full, signals the control cabinet to stop operation and trigger audible and visual alarms so the operator can clean the basket.

Local Control Cabinet

The Control Panel was designed, built, wired, & programmed by our in-house engineers. Incorporating safety measures and programmed to control the system entirely, without external intervention being required other than connecting the pipework up.

The system featured reversing features, stirring functionality, maintenance activities, internal cleaning modes and more. The panel itself is a powder-coated steel enclosure, incorporating a 7” coloured touchscreen HMI, 15kW Inverter, PLC, alarm system and more.

Suction Pipework inside the bunker

Because the ash collection claws constantly operate inside the bunker, robust heavy-duty (SCH160) pipework was used, and specialist protective barriers were welded to bolt over the top of the pipework to prevent/mitigate impacts from the ash claws.

Installation & Commissioning

The custom pump solution for the EfW site was installed by Tapflo Engineers, during the plant’s planned outage. The pump was installed on a concrete plinth and fitted onto stainless steel Unistrut supports where appropriate. The panel was mounted to the bunker wall, with the external cabling being neatly organised in stainless steel cable trays and steel cable tied down for neat cable management.

Phase 1 – Installation:

- Fitted a High-Pressure Peristaltic Pump on a plinth

- Pulsation Dampener fitted to pump discharge during installation

- Vacuum Assist System fitted to Peristaltic Pump

- Mains breaker and isolation feed to control panel & installed

- Phase one installation before panel and further supports

Phase 2 & 3 – Installation and Commissioning:

The system was then successfully commissioned by Tapflo engineers, who ran through the features of the system on-site, ensuring correct operation. Safety concerns were checked, including checking fuses / MCB / internals, tug testing wires, correct cable management etc.

Training & Documentation

Five training days were provided by Tapflo UK to ensure all operators, maintenance staff, and electrical staff could correctly use, maintain, and interact with the system.

Due to the type of industry the client serves, documentation was provided. This includes, but is not limited to:

- Bespoke (System & Client Specific) IOM Manual for the complete system

- Performance, suction capability, hydrostatic and electrical load testing

- Preventative Maintenance Planning

- I/O Lists

- Functional Analysis

- Quality Documents (including welding certificates & procedure for pipework, complete system CE / UKCA certification, system acceptance etc)

- Manufacturing Programs

- Supplier Equipment Declarations

- Training Support Documentation

If you are looking for a custom pump solution for an EfW site, our team of expert engineers can design and manufacture a bespoke system specifically designed for your application. Call us today on: 02380 252 325 or email us at: enquiries@tapflopumps.co.uk.