| Pump Size | Motor Power kW | Pump Speed RPM |

|---|---|---|

| PT 5 | 0.25 | 11, 15, 19, 23 |

| PT 10 | 0.25 | 0.37 | 0.55 | 11, 15, 19, 23 | 15, 23, 25, 35 | 43, 47, 61 |

| PT 15, PT 20 | 0.37 | 0.55 | 15, 23, 25, 35 | 43, 47, 61 |

| PT 25 | 1.5 | 2.2 | 23, 30, 35, 44, 50 | 60 |

| PT 32, PT 38 | 1.5 | 2.2 | 20, 25, 31 | 34, 44, 50, 61 |

| PT 40 | 2.2 | 3 | 4 | 25, 31, 33, 41 | 47 | 54, 63 |

| PT 51, PT 60 | 5.5 | 7.5 | 26 | 20, 33, 38, 47, 55, 60 |

| PT 65, PT 80, PT 80L | 7.5 | 11 | 15 | 20 | 20, 26, 32, 38 | 22,5, 26, 32, 38 |

| PT 100 | 15 | 18.5 | 22 | 18, 24 | 18 | 24, 31 |

| PT 125 | 22 | 30 | 37 | 20 | 25, 32 | 20, 32, 38 |

| Pump Size | Motor Power kW | Pump Speed RPM |

|---|---|---|

| PT 5 | 0.25 | 11, 15, 19, 23 |

| PT 10 | 0.25 | 0.37 | 0.55 | 11, 15, 19, 23 | 15, 23, 25, 35 | 43, 47, 61 |

| PT 15, PT 20 | 0.37 | 0.55 | 15, 23, 25, 35 | 43, 47, 61 |

| PT 25 | 1.5 | 2.2 | 23, 30, 35, 44, 50 | 60 |

| PT 32, PT 38 | 1.5 | 2.2 | 20, 25, 31 | 34, 44, 50, 61 |

| PT 40 | 2.2 | 3 | 4 | 25, 31, 33, 41 | 47 | 54, 63 |

| PT 51, PT 60 | 5.5 | 7.5 | 26 | 20, 33, 38, 47, 55, 60 |

| PT 65, PT 80, PT 80L | 7.5 | 11 | 15 | 20 | 20, 26, 32, 38 | 22,5, 26, 32, 38 |

| PT 100 | 15 | 18.5 | 22 | 18, 24 | 18 | 24, 31 |

| PT 125 | 22 | 30 | 37 | 20 | 25, 32 | 20, 32, 38 |

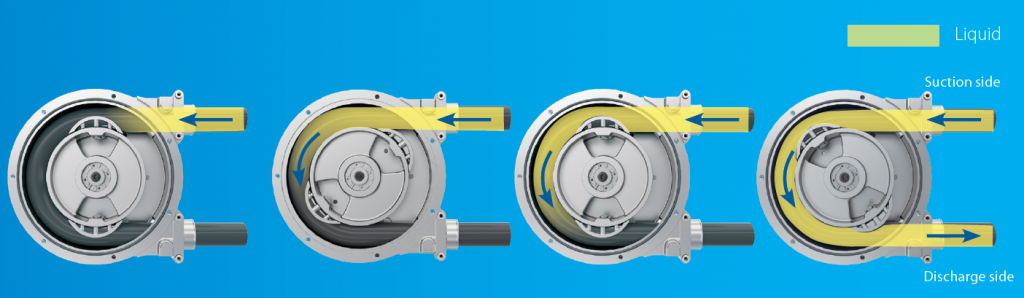

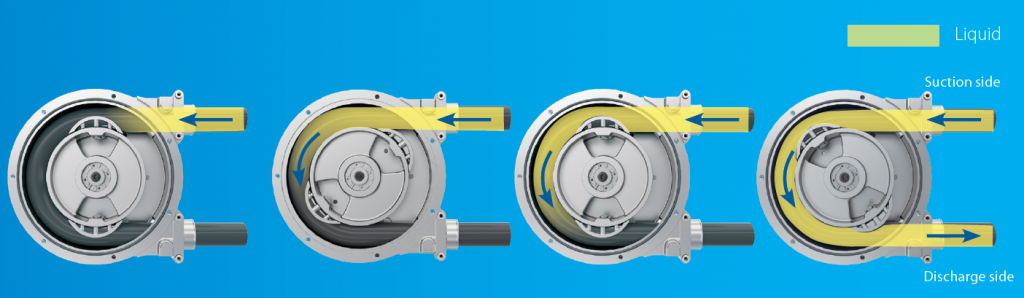

Our High Pressure Peristaltic Pump is a versatile pumping solution designed to handle fragile and shear-sensitive fluids across a range of industrial high-pressure applications. This self-priming pump, capable of handling viscosities up to 100,000 cPs, features a shoe design that requires constant lubrication with glycerin in order to effectively dissipate heat due to friction. Additionally, if you operate in hazardous environments, the PXT, which is the ATEX-rated high-pressure variant of this pump, ensures the utmost safety and peace-of mind in these environments.

Typical applications for our High Pressure Peristaltic Pump:

Download Brochure

Download Manual

Our PT High Pressure Peristaltic Pump features a shoe design which means the pump generates friction and heat while compressing the hose, and so constant lubrication with glycerin is needed to dissipate the heat:

Additionally, our newly upgraded hoses outperform standard hoses, lasting around 30% longer than any hoses in the market today. Our hoses are characterised by their non-machined external surface, which enhances the lubrication of our reinforced hoses. This feature ensures superior grip for the lubricant, significantly lowering heat generation and reducing friction.

Our PT High Pressure Peristaltic Pump features a shoe design which means the pump generates friction and heat while compressing the hose, and so constant lubrication with glycerin is needed to dissipate the heat:

Additionally, our newly upgraded hoses outperform standard hoses, lasting around 30% longer than any hoses in the market today. Our hoses are characterised by their non-machined external surface, which enhances the lubrication of our reinforced hoses. This feature ensures superior grip for the lubricant, significantly lowering heat generation and reducing friction.

| Technical Data | Specification |

| Casing Material | Nodular Cast Iron (standard) |

| Hose Material (wetted) | Industrial reinforced: NR (standard), NBR, EPDM, CSM Food grade reinforced: NR FDA, BR FDA, EPDM FDA |

| Insert Material (wetted) | AISI 316L (standard), PTFE, PP |

| Connection Type | EN1092-1 Flange (std), ANSI flange, BSP/NPT thread, Camlock, Barhose tail, DIN 32676 clamp, DIN 11851 thread, SMS 3017 clamp |

| Motor* | IEC standard, 3-phase, 4-pole, 50/60 Hz, IP55+PTC |

| Max Capacity | 60m3/h |

| Max Viscosity | 100 000 cP*** |

| Max Liquid Temperature | 80 ºC** |

| Max Discharge Pressure | 15 Bar |

| Max Suction Lift | -0.9 Bar |

*Other motor options available on request

**At a room temperature of 20°C (also dependant on the pumped fluid and hose material)

***Maximum value may vary depending on pump size and installation

Available Hose Materials:

| Hose | ATEX | Industry | ||||||||

| Water Treatment | Ceramic | Mining & Quarries | Building & Construction | Chemical | Food & Beverage | Pharma & Cosmetics | Print, Pulp & Paper | Agriculture & Biogas | ||

| Industrial | ||||||||||

| NR | X | X | X | X | X | X | X | X | ||

| NBR | X | X | X | X | ||||||

| EPDM | X | X | X | X | X | X | X | X | X | |

| CSM | X | X | X | X | ||||||

| Food Grade | ||||||||||

| NR FDA | X | X | X | |||||||

| NBR FDA | X | X | ||||||||

| EPDM FDA | X | X | ||||||||

Special Frame Options:

Special Coatings:

Special Executions:

Spare Parts Kit:

Installation Options:

Mounting Positions:

Connection Types:

Insert Materials:

Bracket Materials:

Hose Materials:

Frequency Inverters:

Electrical Cabinets:

Drive Options:

Sensors:

Vacuum Systems:

Trolleys:

Pulsation Dampeners: