| Model | Connections (HDPE/PTFE) BSP inv. | Connections (Metal) BSP inv. |

|---|---|---|

| DT9/20 | 3/8″ | – |

| DT50 | 1/2″ | – |

| DT100 | 1″ | – |

| DT200 | 1 1/2″ | – |

| DT400 | 2″ | – |

| DT800 | – | – |

| DT25 | – | 1/2″ |

| DT70 | – | 3/4″ |

| DT120 | – | 1″ |

| DT220 | – | 1 1/2″ |

| DT420 | – | 2″ |

| DT820 | – | 3″ |

| Model | Connections (HDPE/PTFE) BSP inv. | Connections (Metal) BSP inv. |

|---|---|---|

| DT9/20 | 3/8″ | – |

| DT50 | 1/2″ | – |

| DT100 | 1″ | – |

| DT200 | 1 1/2″ | – |

| DT400 | 2″ | – |

| DT800 | – | – |

| DT25 | – | 1/2″ |

| DT70 | – | 3/4″ |

| DT120 | – | 1″ |

| DT220 | – | 1 1/2″ |

| DT420 | – | 2″ |

| DT820 | – | 3″ |

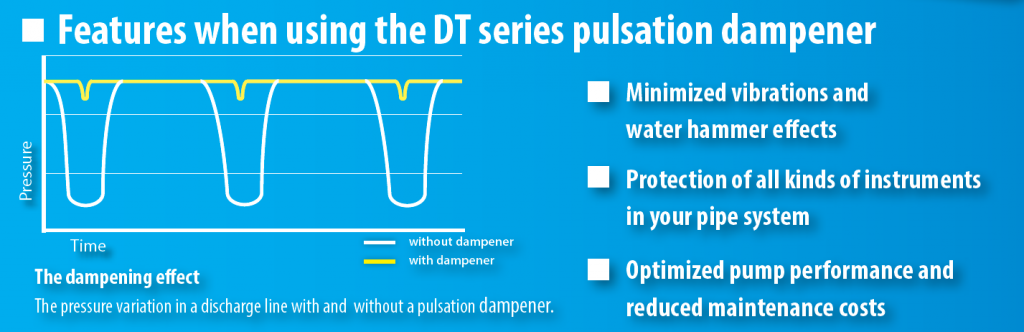

Our DT Series Active Pulsation Dampener is the most efficient way to remove pressure variations on the discharge of your Diaphragm Pump. Available in HDPE/PTFE, Metal and Sanitary executions, this Pulsation Dampener works in tune with the Diaphragm Pump it's fitted to, automatically setting the correct pressure in order to minimise pulsations in the fluid from the pump's outlet. The DT Pulsation Dampener is available for all Tapflo pump sizes and materials, with ATEX-rated metal dampeners, as well as Sanitary dampeners for CIP/SIP, available on request.

Typical applications for our Pulsation Dampener:

Download Brochure

Download Manual

Our DT Series Active Pulsation Dampeners are available in HDPE/PTFE, Metal, and Sanitary executions, allowing you to get the best out of our dampeners depending on your application.

What makes Tapflo’s DT Active Pulsation Dampener different?

Our Pulsation Dampener is available in a Sanitary design perfect for the food, beverage, pharmaceutical and cosmetic industries where cleanliness and a sterile environment are necessary. The dampener is designed and prepared for cleaning and sterilisation in place (CIP and SIP). The DT Active Pulsation Sanitary Dampener is automatic cleaning and disinfection procedures implemented in these industries so it is essential that our products are prepared to comply with these procedures. Dampeners made of stainless steel AISI 316L, electro-polished and offer great mechanical strength combined with good chemical resistance. AISI 316 is resistant to aggressive and abrasive liquids. The dry part of the dampener that does not come into contact with the pumped product is, as a standard, made of corrosive-resistant PP. ATEX-rated Metal Dampeners are also available. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM (conductive).

Our DT Series Active Pulsation Dampeners are available in HDPE/PTFE, Metal, and Sanitary executions, allowing you to get the best out of our dampeners depending on your application.

What makes Tapflo’s DT Active Pulsation Dampener different?

Our Pulsation Dampener is available in a Sanitary design perfect for the food, beverage, pharmaceutical and cosmetic industries where cleanliness and a sterile environment are necessary. The dampener is designed and prepared for cleaning and sterilisation in place (CIP and SIP). The DT Active Pulsation Sanitary Dampener is automatic cleaning and disinfection procedures implemented in these industries so it is essential that our products are prepared to comply with these procedures. Dampeners made of stainless steel AISI 316L, electro-polished and offer great mechanical strength combined with good chemical resistance. AISI 316 is resistant to aggressive and abrasive liquids. The dry part of the dampener that does not come into contact with the pumped product is, as a standard, made of corrosive-resistant PP. ATEX-rated Metal Dampeners are also available. They are supplied with earth connection and conductive materials: conductive body, diaphragm in PTFE (conductive backing) or EPDM (conductive).

DT Series – Active Pulsation Dampener

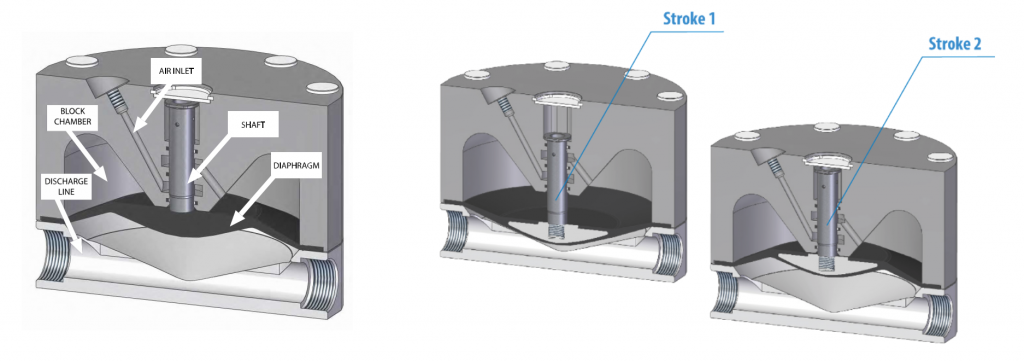

The air pressure supplied to the dampener is the same as the one supplied to the pump. When the pressure in the piping system decreases, due to the pulsating nature of the pump operation, the pulsation dampener supplies extra pressure to the discharge between the pump strokes, therefore supplying a steady flow of the pumped medium. This pumping action created by the dampener decreases the pressure variations and pulsations.

HDPE/PTFE Pulsation Dampeners Technical Data:

| Size | Connections BSP Inv. |

| DT9/20 | 3/8″ |

| DT50 | 1/2″ |

| DT100 | 1″ |

| DT200 | 1 1/2″ |

| DT400 | 2″ |

| DT800 | – |

Metal Pulsation Dampeners Technical Data:

| Size | Connections BSP Inv. |

| DT25 | 1/2″ |

| DT70 | 3/4″ |

| DT120 | 1″ |

| DT220 | 1 1/2″ |

| DT420 | 2″ |

| DT820 | 3″ |