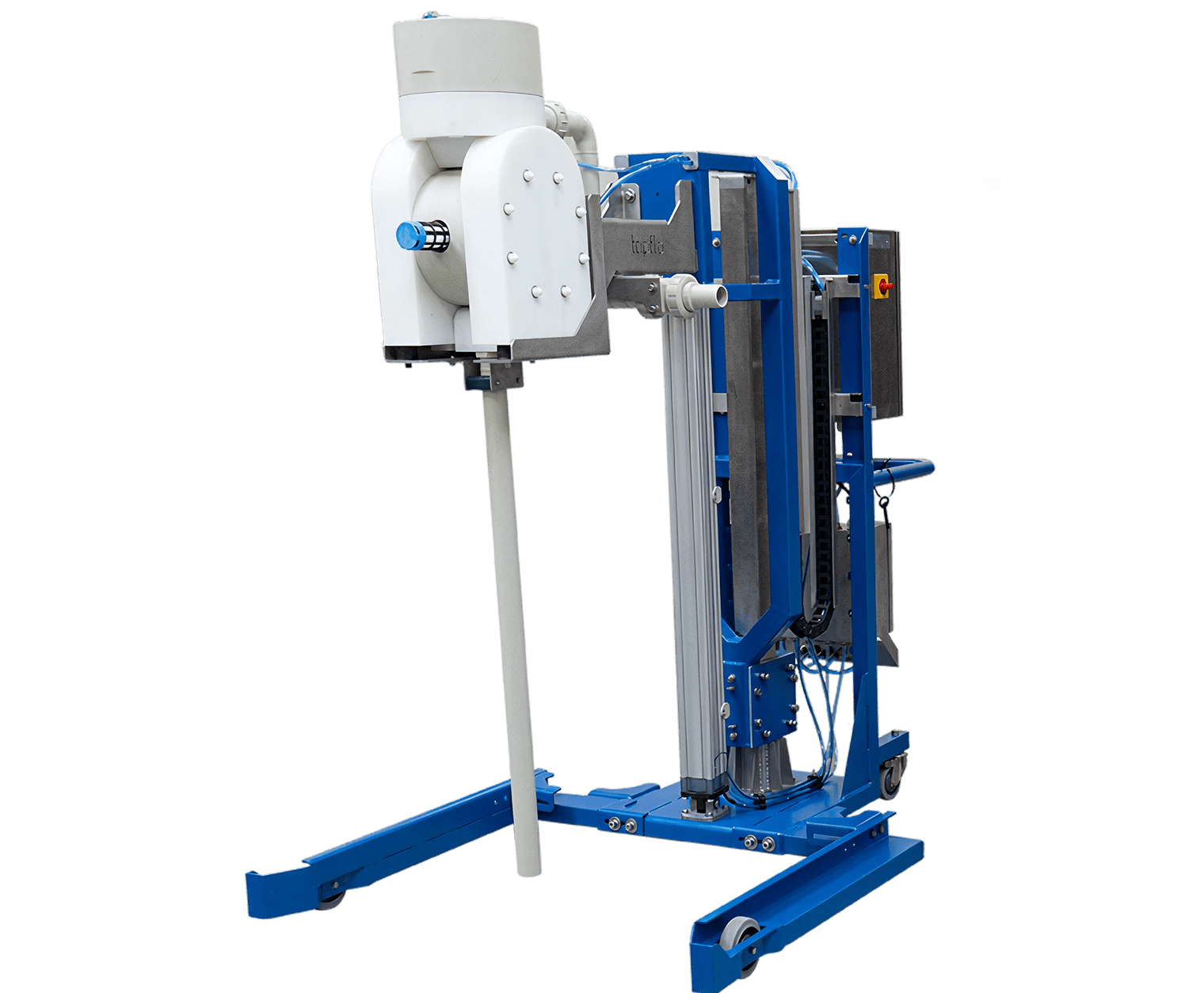

The IBC Unloader, featuring an Air Operated Diaphragm Pump, is a mobile, pneumatically operated system designed to unload low to high viscosity liquids safely and efficiently.

Commonly used across Chemical and Food & Beverage applications, this robust system is suited to a wide range of container types, including IBCs, Mauser, Goodpack, Bag-in-Box®, totes, drums, and custom vessels, offering versatility and high-performance while ensuring operational safety. Designed with a suction lance and customisable control interface, the IBC Unloader supports both manual and fully automated operations, including compatibility with ATEX Zone 1 environments.

Delivers flow rates of up to 200L/min, available in both the standard and ATEX system variants

For superior chemical and corrosion resistance, the system is built with materials such as Polyethylene, PTFE, and Stainless Steel

Featuring an Air Operated Diaphragm Pump with actuator control, this system ensures consistent and safe liquid transfer

Available as a standard or ATEX-rated system suitable for Zone 1 hazardous areas (Ex II 2G IIB T3 certified models)

Constructed with a durable 4-wheel chassis with brakes for easy mobility and portability as well as secure positioning

Supports a range of containers, including IBCs, drums, barrels, totes, Mauser, Goodpack, Bag-in-Box®, and custom vessels

START/STOP operation, batch mode option, automatic lance lowering and adjustable flow via the air needle valve

Emergency stop, leak prevention and process controls for safe, dependable performance across varied industries

Hover for more information

Lance Positioning

Auto (pneumatic) or manual winch. Both ATEX-ready

Height Adjustable

Works with IBCs, drums, and custom containers

Smart Controls

Choose pneumatic or electric panel. Radar sensor optional

Automation Ready

Auto stop/start when the container empties/refills

Emergency Stop

One-touch process shutdown

Dry Run Safe

The pump can safely dry run without causing damage

Need hands-free operation? Choose the pneumatic lance and radar control for fully automated unloading.

· IBCs (Intermediate Bulk Containers)

· Mauser containers

· Goodpack containers

· Bag-in-Box containers

· Totes

· Drums and barrels

· Custom client-specific vessels

· Chemical

· Food

· Wastewater

· Paper

· Surface treatment

· Electronics

· Printing

The system supports flow rates of up to 200 l/min, suitable for both low and high-viscosity products.

It features an Air Operated Double Diaphragm Pump (e.g., Tapflo TK200 PTT) with PTFE diaphragms and valve balls, and an integrated pulsation dampener.

· Polyethylene

· PTFE

· Stainless Steel

The lance can be positioned using:

· A pneumatic actuator for automated operation

· A manual winch for precise manual adjustment (both options are available in standard and ATEX-compliant versions)

It features a user-friendly START/STOP interface, with optional customisable batching capabilities.

Yes, the system supports automated lance lowering, enabling unattended operation.

Yes, our Unloading System is electrically and pneumatically operated, with pneumatic pumps and articulation, with electro-pneumatic control panels.

Ready to build a system tailored to your needs? Speak to our team today.