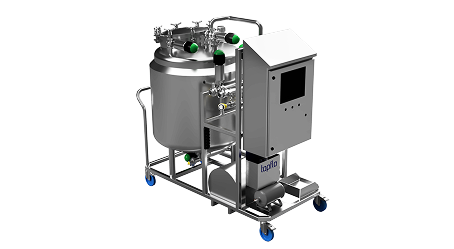

Our Mobile CIP System is a compact and versatile cleaning solution tailored for smaller operations or facilities requiring flexibility. With skid-mounted and wheel-mounted options available, it offers portability and efficiency without the commitment of a centralised system.

Designed for easy mobility, this caster or skid-mounted system brings cleaning directly to the equipment, ideal for tight spaces or frequently changing layouts.

The system features a 350L tank, in-tank heating, a high-efficiency pump, and butterfly valves for multi-point cleaning. It also reuses cleaning solutions to reduce waste & lower operating costs.

Ideal for microbreweries, labs, artisanal food processors or small healthcare facilities, this mobile system fits a range of equipment sizes and supports varying automation levels.

With integrated in-tank heating, this system can deliver hot water cleaning cycles using only a cold water feed, simplifying utility requirements while ensuring high-temperature sanitation.

With real-time flow rate, temperature, and chemical concentration monitoring, plus data logging to CSV via USB, the system supports quality assurance and compliance with regulatory standards

With options like automated chemical dosing, electric heating, Ethernet communications, and adjustable feet for levelling, this system is modular, scalable, and ready to evolve with your facility’s future needs

Automated cleaning steps reduce exposure to chemicals and physical strain on operators. Built-in emergency stops and overflow protection enhance overall safety.

Constructed from Food-Grade 316 Stainless Steel for all wetted parts, the unit resists corrosion and ensures hygiene across industries from beverage to biotech

Secure, end-to-end encryption enables remote diagnostics and updates, cutting downtime and speeding up support.

Pre-Rinse | with recovered water

Temp | Ambient °C

Duration | 5 – 10 min

Alkali Clean | 2% Caustic Solution

Temp | 70–80°C

Duration | 10 – 20 min

Inter-Rinse | with process water

Temp | Ambient °C

Duration | 5 – 20 min

Acid Clean | 1% Phosphoric Acid

Temp | 50–70°C

Duration | 2 – 10 min

Inter-Rinse | with process water

Temp | Ambient °C

Duration | 5 – 20 min

Final Rinse | Quality (Purified) Water

Temp | Ambient °C

Duration | 5 – 20 mins

Air Purge | Sterile Air

Temp | 20–30°C

Duration | 3 – 15 mins

Tank Configuration:

350L

Mobility:

Compact unit with skid or caster wheel mounting

Temperature Range:

20 – 90°C

Automation:

Basic PLC controls with monitoring capabilities

Material:

Food-grade Stainless Steel (304/316)

The system includes a 350L stainless steel cleaning tank with in-tank heating, a high-efficiency Tapflo centrifugal pump, Cipriani Harrison butterfly valves, simplified PLC controls, and an integrated heating system. All wetted parts are made from 316 food-grade stainless steel to ensure hygiene and durability.

For more information on CIP, please refer to some of our guides below.

Designed for small-scale production, the system offers consistent multi-point cleaning, thermal sanitation without external hot water, and remote access for diagnostics and updates. It’s mobile, compact, and easily adaptable to various environments and automation levels.

For more information on CIP, please refer to some of our guides below.

There are! Optional features include automated chemical dosing, ethernet connectivity, adjustable feet, fixed-mount configurations, and enhanced electric heating. These modular upgrades allow users to tailor the system to specific operational needs.

For more information on CIP, please refer to some of our guides below.

The in-tank electric heating system operates between 20°C and 90°C, allowing the unit to generate hot water cycles from a cold-water feed with no external hot water source required. This makes it ideal for compact, independent operations.

For more information on CIP, please refer to some of our guides below.

All wetted parts are made from 316 Food-Grade Stainless Steel for maximum hygiene and corrosion resistance. The rest of the unit uses a mix of 304 and 316 stainless steel, selected based on each component’s exposure and function.

For more information on CIP, please refer to some of our guides below.

Ready to streamline your cleaning? Speak to our team to explore a system built around your needs.