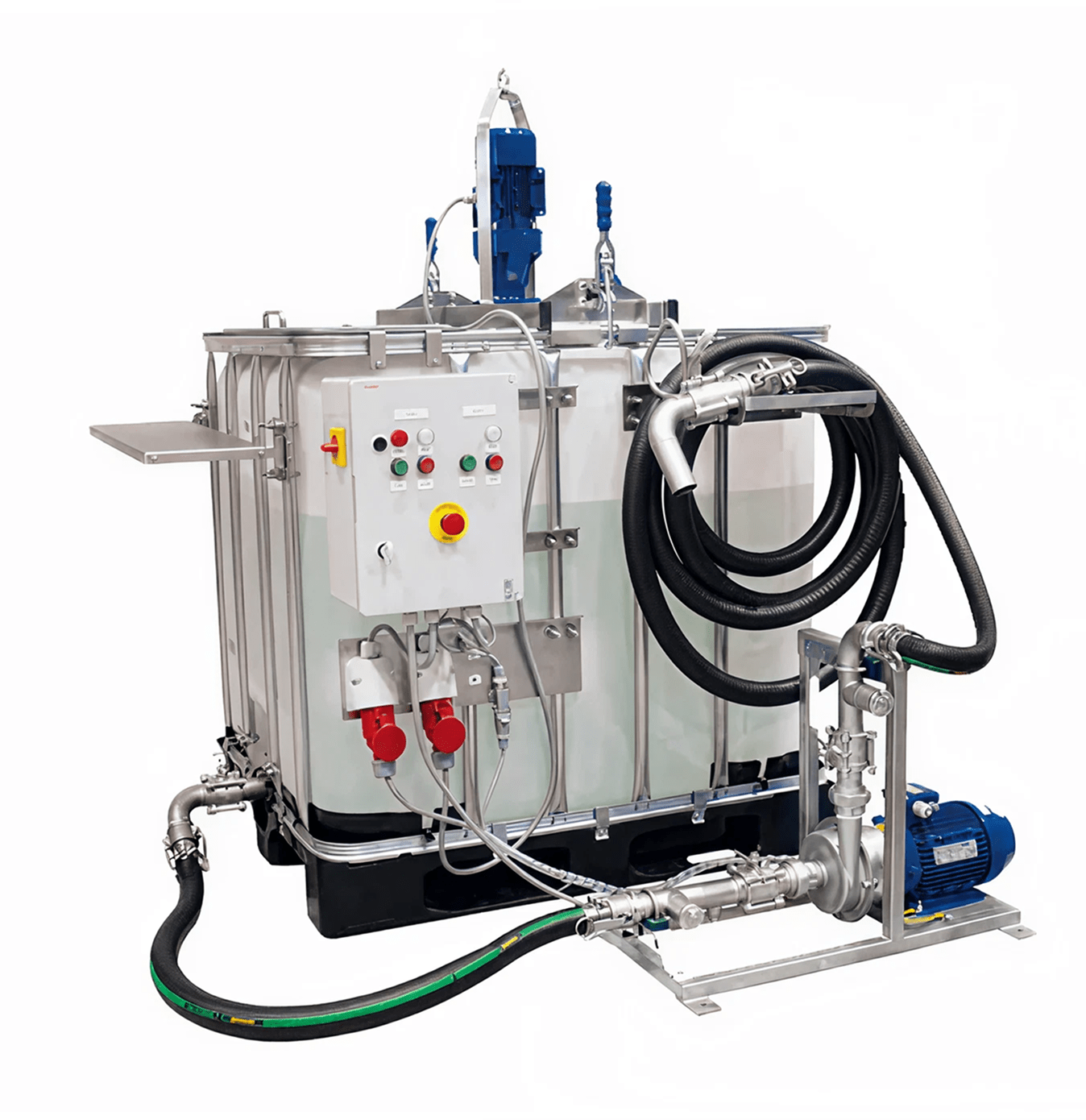

Tapflo’s Mixing & Pumping Station is a modular and flexible system designed to dilute, mix, and transfer a wide variety of liquids, powders, and fertilisers. Featuring a 1000L tank and integrated mixing system, it combines reliable agitation with a Centrifugal Pump for quick product transfer.

This system is ideal for applications where powders, granulates, or concentrated chemicals need to be diluted before use. Both standard and customised executions are available to fit IBCs, drums, and other storage vessels, all tailored to your application’s requirements.

Integrates mixing, dilution, and pumping in one compact station

Centrifugal Pump ensures fast discharge of prepared mixtures

Hatch opening and support shelf for easy powder/fertiliser loading

Local control cabinet with light indication; interlocks available

Portable and stationary options to suit site requirements

Built from high-quality materials for reliable, long-term use

Suitable for hazardous zone installations

Adaptable to IBCs, drums, or other tanks

Hover for more information

Ready to mix efficiently? Ready to mix efficiently? Talk to our team to explore mixers built to your needs

Tank Capacity

1000L as standard (custom volumes are available on request)

Mixing Method

Built-on IBC Mixer

Transfer Method

Centrifugal Pump with outlet hose, nozzle and valve

Power Supply

Electric or pneumatic drives are available

Installation Options

Stationary (floor/wall mounted) or portable (mobile unit with wheels)

Construction Materials

Configurable depending on your application and the chemical compatibility of the fluid being pumped

ATEX Executions

Available for explosive zones and hazardous areas

Customisation Options

Tailored designs for IBCs, drums, or site-specific vessels, all configured to your application needs

It’s designed to dilute, mix, and immediately transfer liquids such as fertilisers, powders, chemicals, and wastewater treatment agents.

Yes. Standard executions are available, but Tapflo UK also manufacture custom Process Engineering & Design solutions adapted to customer-specific IBCs, tanks, or processes.

A 1000L tank is supplied as standard, but other capacities can be manufactured on request.

A Centrifugal Pump quickly transfers the prepared mixture via an outlet hose, nozzle and valve.

Yes! ATEX-rated versions are available on request.

Both stationary installations (fixed to the floor or wall) and portable versions (mobile unit on wheels) are available, depending on your application requirements.

Yes. The hatch opening and support shelf are designed to safely and conveniently add powders or fertilisers during operation.

Designed to simplify even the most demanding processes, our all-in-one station delivers efficient and repeatable results.