What is Pump Efficiency?

Simplified, pump efficiency is how well a pump converts the useful energy from a hydraulic power source and transfers it to the pump output. As an example, if an electric motor was to provide X amount of energy to a machine, and the output is 1/X (Half of X), then the efficiency of the machine is 50%. This is because 50% of the energy has not been used on the primary output of the machine, and as such is ‘wasted’ energy.

This ‘wasted’ energy can come in many forms for a pump, such as excessive noise or heat generation. For a pump transferring fluid from Point A to Point B, noise and heat are not desirable forms of energy for us (in most cases), so we classify them as ‘wasted’ energy.

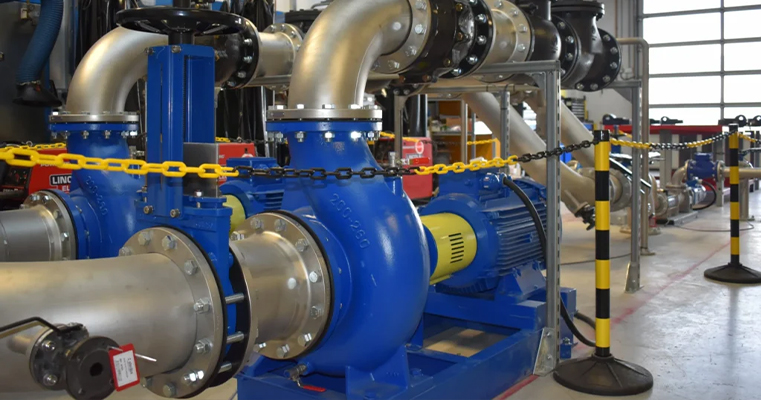

All pumps offer different levels of efficiency; if you’re using Centrifugal Pumps, our guide on Achieving Maximum Efficiency for your Centrifugal Pump may be useful.

Why is Pump Efficiency Important?

In short, a more efficient pump saves you money.

A highly inefficient pump will waste energy when moving fluid in a system, resulting in higher electricity costs to power the pump. There is also the element of maintenance costs; an inefficient pump will wear quicker than an efficient pump, meaning a loss in revenue income (because the pump is not functioning, stopping production), more labour and time to getting the pump up and running, and more spares being required per year to repair the pump.

What Influences the Overall Efficiency of a Pump?

Overall pump efficiency is what you would use to determine the amount of wasted energy loss throughout a pump, which can be defined as the ratio of the actual power output to the actual power input. There are three elements that influence and change a pumps overall efficiency:

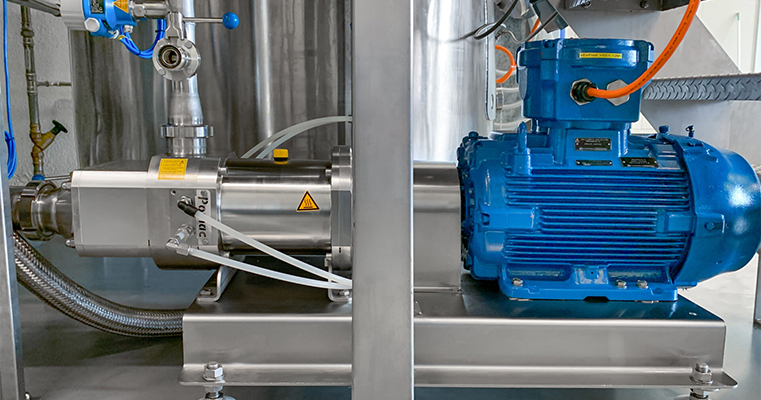

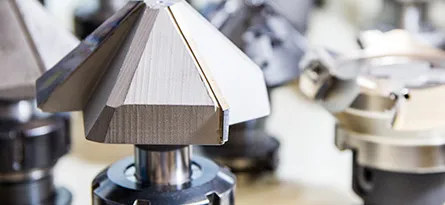

- Mechanical: This is the efficiency used to calculate and identify the power lost in moving parts of the pump, such as bearings, stuffing boxes, mechanical seals etc. This can be defined as the ratio of theoretical power the pump requires to the actual power delivered to the pump itself.

- Volumetric: Volumetric efficiency is used to calculate and identify the liquid lost through balancing holes and wear rings. This also includes the clearances between the pump casing and impeller vanes for semi-open or open impeller designs. This can be defined as the ratio of the actual flow rate that the pump provides to the theoretical discharge flow rate.

- Hydraulic: This is perhaps the most important factor to consider, as it calculates & identifies the losses of liquid friction and other losses inside the volute and impeller. This can be defined as the ratio of useful hydrodynamic energy (in the form of fluid) to the amount of mechanical energy delivered to the rotor.

How to Calculate Pump Efficiency

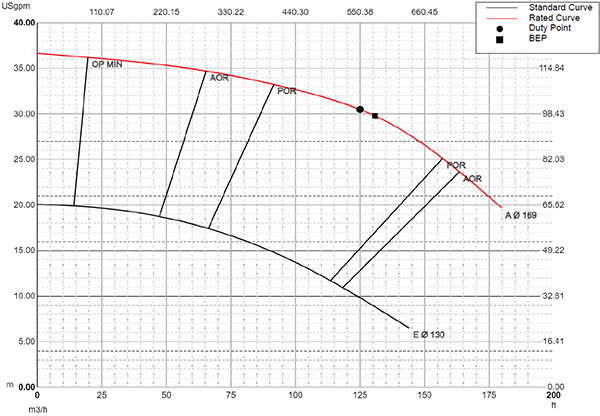

Example of Pump Efficiency Curve

Pump Efficiency (η) = (Q × H × p) / (367 × P2)

Q = Flow (m3/hr)

H = Delivery Head (m)

p = Density of fluid (kg/dm3)

367 = Conversion Constant

P2 = Power Consumption at pump shaft (kW)

What is BEP?

BEP stands for Best Efficiency Point and is the best point on the performance curve of where the pump can perform. At the BEP, the fluid enters the pump suction and leaves the discharge with the least amount of wasted energy possible.

What if I cannot reach the BEP?

Whilst you would not be directly achieving the best scenario for the pump, that doesn’t mean the pump will break immediately or that it cannot handle the application.

Another acronym that is closely tied to the BEP is the POR. This is the Preferred Operating Region (or Preferred Operating Range) and is the preferred place to operate the pump, as sometimes it is not always possible to operate at the exact BEP point. The POR can vary in size depending on the design of the pump, however, it is generally within 70% to 120% of the BEP point.

Operating within the POR is crucial to ensuring the pump will last as long as possible, as the hydraulic efficiency and operational reliability are not reduced substantially. Inside the range, the service life of the pump is not affected by the internal hydraulic loads or vibration.

There is another region on a pump curve called the AOR, which means Allowable Operating Region (or Allowable Operating Range). This is the area of performance where the pump can still perform, and the service life of the pump is still within acceptable standards.

What happens if I operate outside the AOR?

Bad things happen outside the AOR. It doesn’t always happen straight away, however, when operating outside the AOR, you will see excess wearing which costs money to rectify.

And if you’re operating as far left or as far right of the curve as you possibly can, then the pump is likely to fail almost immediately.

What can I do to use a pump that’s reaching BEP?

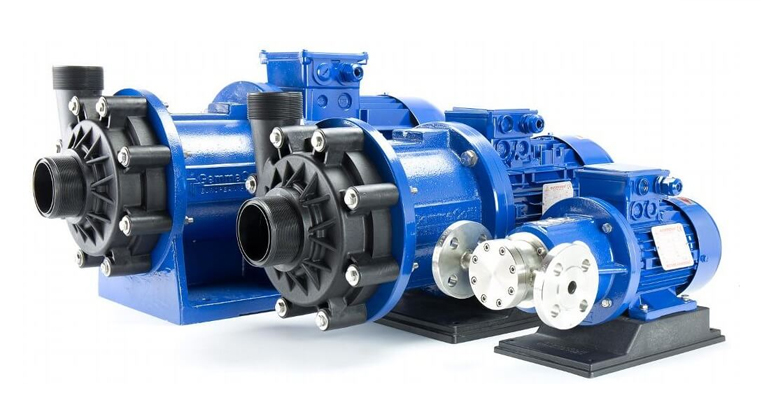

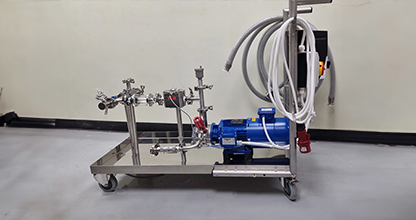

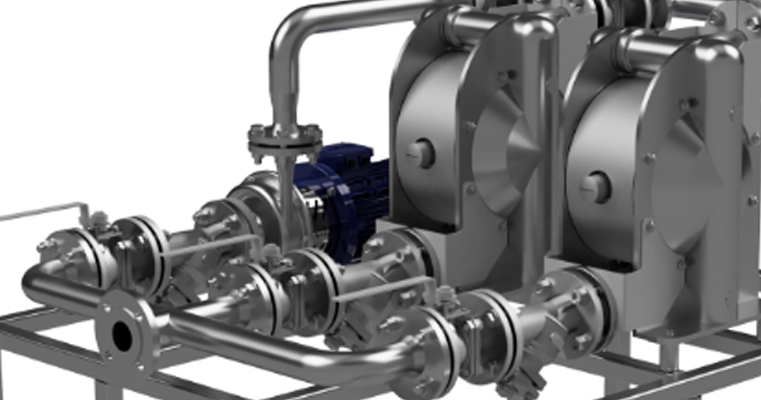

There are many ways of ensuring you have the most efficient pump possible for your process. There are almost countless designs of pumps available, each with strengths and weaknesses which influence efficiency & reliability. One common way of increasing overall pump efficiency for a process is to utilise a bigger pump and run it at a slower RPM speed.

Bigger pumps, especially centrifugal pumps, have a higher % BEP. On average, small centrifugal pumps have BEP of 40 – 50%, whereas large centrifugal pumps have BEP of 70 – 80%, with some achieving 90%. We here at Tapflo pride ourselves on high-efficiency systems & services, so please consult with our team for the best possible pump for your process!