Tapflo’s SLES Mixing & Dilution Unit system is fully automated and designed to dilute highly concentrated SLES (70%) down to process-ready concentrations of up to 27%.

Engineered for precision and reliability, the unit features accurate dosing, robust stainless steel construction, and advanced automation to deliver consistent, high-quality results while significantly reducing operational costs and production downtime.

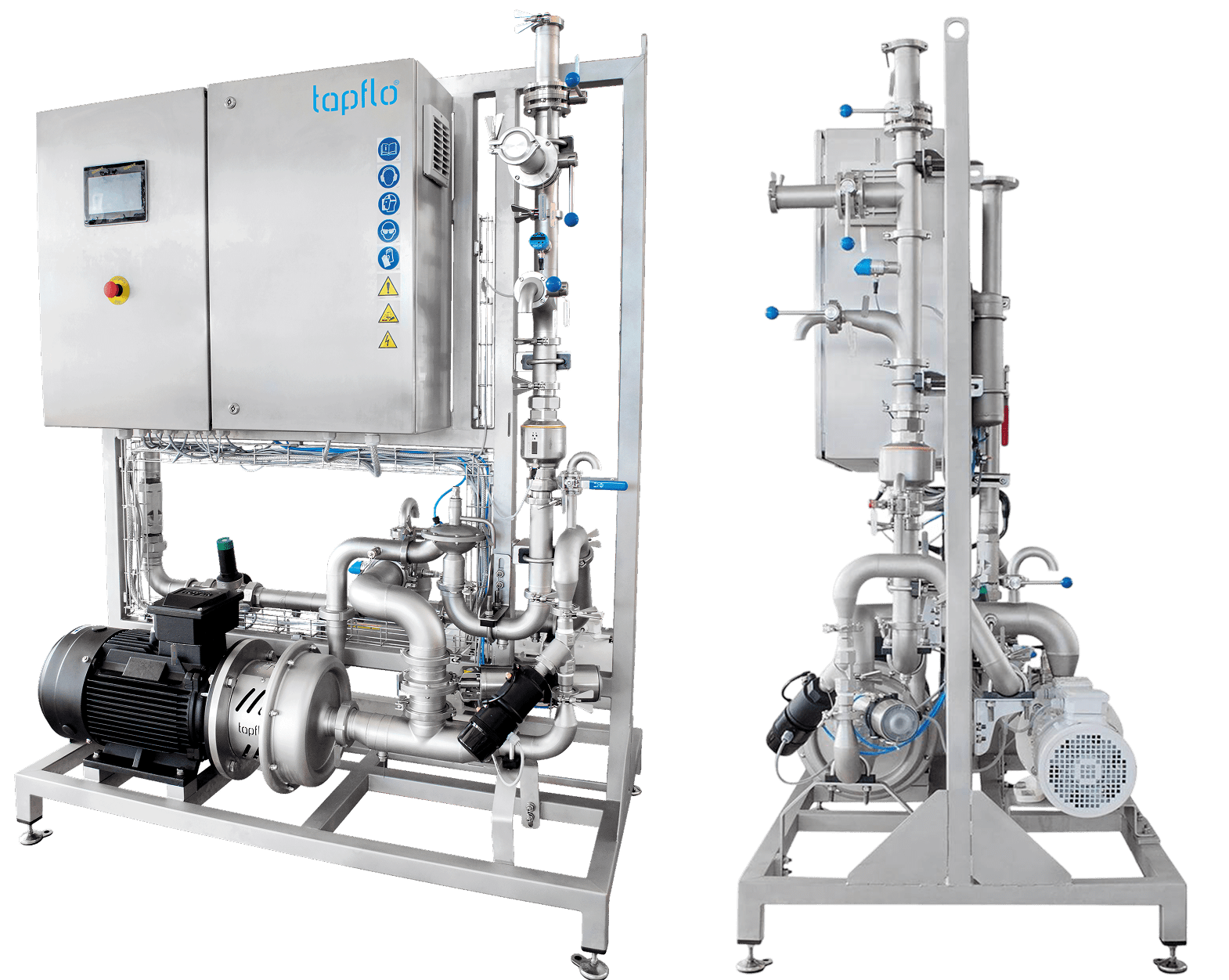

The system incorporates a Progressive Cavity Pump for precise handling of viscous SLES and a Centrifugal Pump for efficient mixing and transfer, ensuring a homogeneous and stable solution with every batch.

Skid-mounted and fully PLC-controlled, it allows operators to easily set concentration, flow rate, and batch size, with all parameters continuously monitored and recorded for complete process control.

Buy concentrated SLES and dilute in-house, reducing purchase, transport, and storage costs

Continuous or batch supply at desired concentration

Immediate start-up, no waiting for pre-mixing

Energy-saving in-line dilution eliminates heating and manual mixing

Stable, homogeneous solutions with precise concentration control

Full traceability of operational parameters via PLC/HMI

Skid-mounted, stainless steel, small footprint

Optional dosing of additional ingredients (e.g., Betaine) or tanker loading

Hover for more information

The Progressive Cavity Pump transfers concentrated 70% SLES into the mixing line

A Centrifugal Pump blends SLES with water to the required concentration

The PLC system adjusts flow rates and pump speeds based on operator settings (concentration, batch size, flow)

Flow meters, temperature/pressure sensors, and transducers continuously track process conditions

A stable, homogeneous SLES solution at the exact concentration (27%) is discharged for immediate use

Flow Rate (SLES Solution)

Up to 30m³/hr, various sizes available

Discharge Pressure

Up to 6 Bar G

Concentration of Obtained SLES Solution

0 – 27%

Pumps

A progressive Cavity Pump to feed the 70% SLES solution, and a Centrifugal Pump for mixing SLES with water, and pumping out the final solution

Control & Automation

Control Unit including PLC with touch screen, pressure transmitters, temperature transmitter, frequency inverters, flowmeters, and valves with a dedicated control system

Piping Material

AISI 316 Stainless Steel

Frame Material

AISI 304 Stainless Steel

Standard units deliver 5 or 10 m³/h. Custom systems are available up to 30 m³/h.

The system allows 0 – 27%, with stable, homogeneous solutions.

Yes, the compact skid design and PLC/HMI interface make integration seamless.

Yes. Optional extensions allow dosing of additional liquids such as Betaine.

Yes. A remote support module enables online commissioning, monitoring, and troubleshooting.

Tapflo’s automated system is faster, safer, more accurate, and far more energy-efficient than manual heating and mixing methods.

Streamline your production with automated dilution for consistent, high-quality SLES solutions every time.