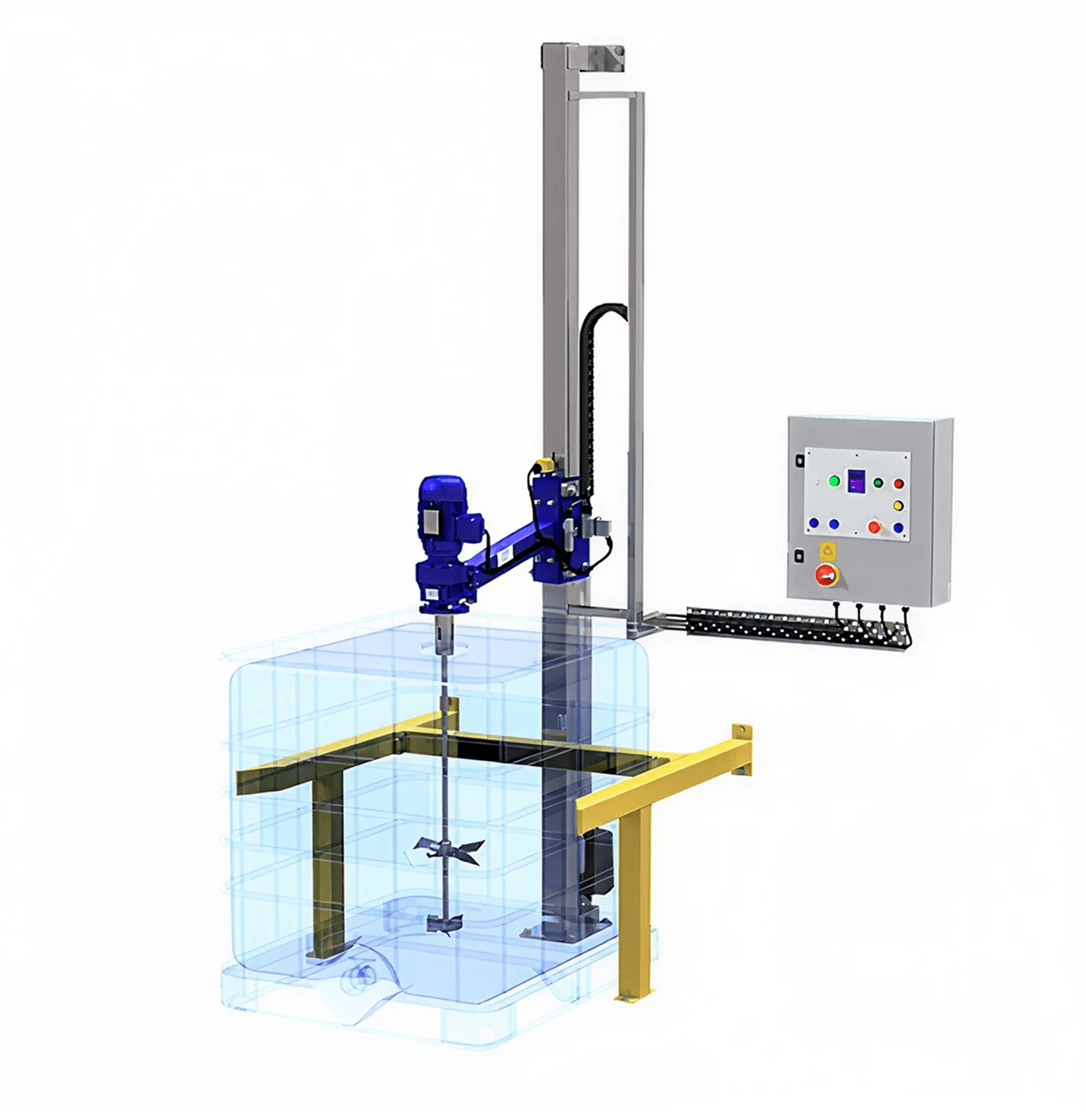

The Tapflo IBC Mixing Station is an automated, high efficiency mixing station for liquids stored in Intermediate Bulk Containers (IBCs). Designed for both stationary and mobile use, it combines safety, ease of operation, and robust construction to deliver reliable performance across a wide range of industries.

With the ability to handle highly viscous liquids up to 20,000 cP, including powders and solids, the IBC Mixing Station ensures uniform mixing directly in the container, eliminating the need for intermediate tanks, reducing manual handling, and optimising production efficiency. Available in ATEX-certified executions, the system is suitable for use in explosive or hazardous environments.

Ensures the Mixer cannot run if the IBC is missing, incorrectly positioned, or raised

Adjustable mixing speed and programmable timer enable consistent results while freeing operators for other tasks

Suitable for liquids up to 20,000 cP, with folding impellers for easy container entry

Available in explosion-proof category II 2G executions

Mobile designs available for use across multiple locations

Convenient placement of IBCs using hand pallet trucks, simple controls, and reliable automation

Robust frame and high-quality materials ensure long service life

Hover for more information

The IBC is placed under the Mixer using a forklift or pallet truck, with guide rails to ensure correct alignment. In mobile executions, the station is wheeled to the container’s location and locked in place

The Mixer is lowered into the IBC via an electric actuator, pneumatic cylinder, or manual rope reel. The folding impeller enters easily through the IBC opening.

The operator sets the rotational speed via the frequency inverter. Mixing time is programmed on the control panel timer. The impeller unfolds inside the container and begins mixing.

The Mixer cannot operate without a correctly placed IBC. It stops automatically if raised above the container level. All rotating elements are enclosed, eliminating the risk of contact.

Once the cycle ends, the unit shuts off automatically and signals the end of mixing. The IBC can then be removed and replaced.

All Pumps Types, All Brands, All Ages All Pumps Types, All Brands, All Ages

Liquid Properties:

Liquids up to 20,000 cP, containing powders and solid particles

ATEX Versions:

Available for explosive/hazardous zones (category II 2G)

Power Supply:

400V AC, 50–60 Hz or 220–230V AC, 50–60 Hz

Dimensions:

1300 × 1200 × 3000 mm (L × W × H)

Materials:

Wetted parts: AISI 316 Stainless Steel, PP, PFA, ECTFE

Frame/other parts: AISI 304 Stainless Steel or painted steel

It automates the mixing of liquids, powders, and suspensions directly in IBCs, improving efficiency and safety compared to manual methods.

Yes. It is suitable for liquids up to 20,000 cP, including solids/powders.

Yes. ATEX-rated executions are available for use in hazardous and explosive zones.

Yes. Mobile designs with lockable wheels are available for use in different locations.

Yes. Drum Mixing executions are available, complete with drum covers, fastening belts, and optional ingredient hoppers.

Through a frequency inverter (electric drives) or pneumatic regulator, depending on the model.

Yes, the station comes equipped with safety interlocks, enclosed moving parts, overload protection, and emergency stops, ensuring safe operation.

Looking for durable, efficient operation with consistent results? Our IBC Mixing Station delivers reliable performance across a range of industries.