As the exclusive UK distributor for Pomac Pumps, Tapflo UK takes pride in bringing you a selection of Sanitary Lobe Pumps that redefine the standards of performance and hygiene. In this blog, we’ll take a closer look at the details of these pumps, specifically highlighting Tapflo’s LPX Lobe Pump and Pomac’s Sanitary Lobe Pump, 2 powerful solutions that cater to the diverse needs of industries requiring optimal sanitation.

What is a Sanitary Lobe Pump?

A Lobe Pump is a robust and compact positive displacement pump that operates with a unique design featuring non-contacting lobes and large pumping chambers. Unlike many other pump types, Lobe Pumps excel in handling solids, making them suitable for delicate substances such as cherries or olives without causing damage. This versatility extends to slurries, pastes and a diverse range of liquids.

Let’s take a look at the key features that make a Lobe Pump sanitary:

- Construction Material: Sanitary Lobe Pumps prioritise the use of high-quality materials, with a common choice being Cast Stainless Steel AISI 316L. This material offers excellent corrosion resistance and durability, crucial for maintaining sanitary conditions

- Surface Roughness: a critical aspect of sanitary design is the surface finish. Sanitary Lobe Pumps are meticulously finished to achieve a smooth surface, often with a surface roughness of <0.8 (or 0.5 upon request). This smooth finish reduces the risk of bacterial adhesion and facilitates effective cleaning

- Design Consideration: the design of Sanitary Lobe Pumps minimises dead spaces where fluids or contaminants could accumulate. This design consideration supports thorough cleaning and prevents the build-up of bacteria, ensuring a hygienic environment

- FDA Compliance/EHEDG Certification: Sanitary Lobe Pumps adhere to FDA (Food and Drug Administration) standards, ensuring that materials used in the pump construction are safe for contact with food and pharmaceutical products. EHEDG (European Hygienic Engineering & Design Group) certification is a hallmark of sanitary design. Lobe Pumps with EHEDG certification meet stringent hygiene and design criteria, making them suitable for industries with high cleanliness standards

- CIP/SIP Capabilities: Sanitary Lobe Pumps are equipped with CIP (Clean-In-Place) and SIP (Sterilisation-In-Place) systems. These features streamline the cleaning and sterilisation processes without requiring disassembly, contributing to efficient maintenance and preventing contamination

- Seals: interchangeable sealing options are a common feature of Sanitary Lobe Pumps. This allows users to select seals that are suitable for specific applications, providing flexibility and ensuring a secure and hygienic seal

- Self-Draining Capabilities: the design of Sanitary Lobe Pumps often incorporates self-draining features, especially when vertically mounted. This ensures that residual liquids are effectively drained, minimising the risk of contamination and simplifying the cleaning process

- Connection Types & Sizes: Sanitary Lobe Pumps offer a variety of connection types and sizes to accommodate different system requirements, including Tri-Clamp Connections, Hygienic Threaded Connections, DIN and BSP Connections, as examples, contributing to the overall cleanliness of the system

Working Principle of a Lobe Pump

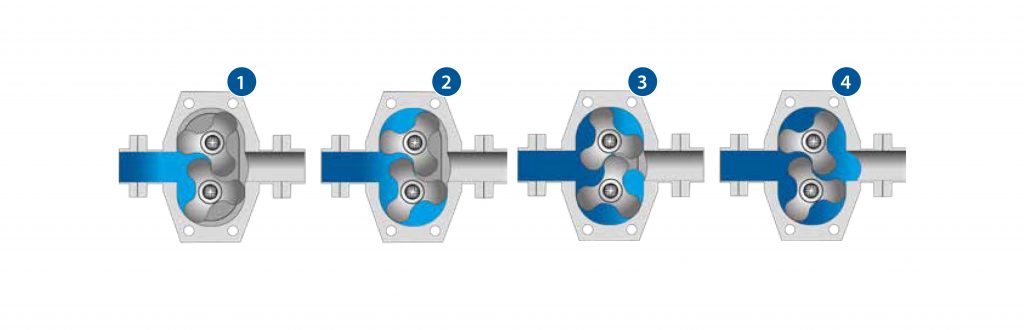

Sanitary Lobe Pump Working Principle:

The two lobes within the pump counter-rotate to create a positive displacement force within the pump casing. The lobes then rotate without touching, and as they rotate within the pump casing, they pass the suction port. The rotating increases the volume of product between the lobes, which then forms a vacuum drawing fluid into the suction port and the pump casing. As the lobes continue to rotate, they drive a predetermined amount of liquid through the pump. When the lobes reach the discharge port, the volume of product between them decreases, creating pressure that causes the product to flow out of the pump casing’s discharge port.

Applications for a Sanitary Lobe Pump

Sanitary Lobe Pumps are ideal for a range of applications that require precision, hygiene and reliability. Here are some key industries where these pumps play a crucial role:

Food Industry:

- Handling Viscous Substances: Sanitary Lobe Pumps excel in managing a range of food products, including highly viscous substances like yoghurt, custard and glucose syrup. The non-contacting design of Lobe Pumps is particularly beneficial for delicate food items, ensuring gentle handling without compromising product integrity

- Processing of Liquid Foods: in the Food & Beverage industry, Lobe Pumps are instrumental in the transfer and processing of liquid foods such as beverages, soups, sauces and dairy products

- Handling Solids: the ability to handle solids makes Sanitary Lobe Pumps suitable for applications involving products with particulate matter, such as fruit purees, jams and sauces

Chemical Industry:

- Versatile Chemical Transfer: Sanitary Lobe Pumps are utilised in the Chemical industry for the transfer of various liquids, including corrosive chemicals, solvents and viscous substances. The robust construction and material compatibility make them suitable for a diverse range of chemical applications

- Slurry Handling: a Lobe Pump’s ability to handle slurries ensures efficiency in applications where the transfer of abrasive or particle-laden liquids is required

Pharmaceutical Industry:

- Precise Medication Transfer: in Pharmaceutical manufacturing, Sanitary Lobe Pumps contribute to the precise transfer of medications, syrups and other pharmaceutical liquids. The EHEDG certification and compliance with regulatory standards ensure the integrity of the pharmaceutical products

- Sterilisation Processes: Sanitary Lobe Pumps with CIP and SIP capabilities are vital for Pharmaceutical applications where sterilisation is a critical requirement to maintain aseptic conditions

Cosmetics Industry:

- Shampoo and Cream Production: Sanitary Lobe Pumps are integral to the production of cosmetic products such as shampoos and creams. Their ability to handle viscous substances ensures the efficient transfer and processing of cosmetic formulations

- Gentle Product Handling: the non-contacting operation of Lobe Pumps is advantageous in cosmetic applications where the gentle handling of ingredients is essential to preserve product quality

Hazardous Environments:

- Potentially Explosive Environments: ATEX-rated options make Sanitary Lobe Pumps suitable for use in potentially explosive environments. This includes applications in industries such as petrochemicals and certain chemical processing plants where adherence to safety standards is crucial

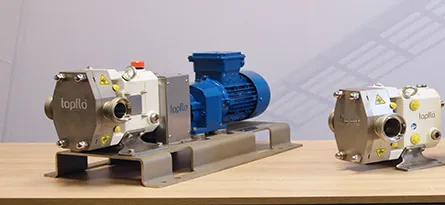

Sanitary Lobe Pumps Supplied by Tapflo UK

- Pomac Sanitary Lobe Pump: Pomac’s Sanitary Lobe Pump is EHEDG compliant, constructed from Cast Stainless Steel AISI 316L and finished with a surface roughness of <0.8 (or 0.5 upon request) for increased corrosion resistance. Ideal for Food, Cosmetic and Pharmaceutical industries, it features CIP and SIP systems for optimal cleaning and sterilisation

- Tapflo LPX Hygienic Lobe Pump: Tapflo’s LPX Hygienic Lobe Pump is a versatile positive displacement pump widely used in hygienic processing. Unlike Gear Pumps, the LPX features non-touching lobes, eliminating cross-contamination. It’s designed for energy efficiency, with bi-directional flow, multiple sizes and FDA-approved materials. Take a look at our Guide To Tapflo’s LPX Hygienic Lobe Pump, answering all your frequently asked questions!

How to Maintain your Lobe Pump?

Maintaining your Hygienic Lobe Pump is simple, providing you carry out regular checks on the pump. Regular maintenance checks will reduce the likelihood of unnecessary downtime for your pump and will reduce breakdown costs. There are already low maintenance costs associated with Lobe Pumps, so following the brief maintenance checklist below will help further:

- Check the gearbox oil level. If the oil level has decreased, this could indicate a leak. Ensure you check the whole pump for any spots where leaking looks like it has occurred. Additionally, the oil in your pump should be changed after operating for 300 hours from its initial installation. After this first oil change, it should be changed every 3 months or every 3000 hours of operation. Lobe Pumps that aren’t used frequently should have their oil changed every 3 months or every 2000 operating hours

- Check that the suction and discharge pressure of your Lobe Pump is at the normal system levels

- If your Lobe Pump comes with the flushing system feature, check the pressure and flow

- Check the sound of your pump This will be an easy maintenance issue to spot. If the Lobe Pump is producing an excessive amount of noise, this could indicate the lobes within your pump are dragging or that there are problems caused by wear to the bearings or gears within your pump

Maintenance of the pump is made simpler by the mechanical seals and lobes ability to be pulled out of the pump through the front of the casing. Get in contact with the sales team on [email protected] for help.

In conclusion, Pomac and Tapflo’s Hygienic Lobe Pumps are a reliable choice for industries requiring efficient, sanitary and versatile pumping solutions. From EHEDG certification to ATEX ratings, these pumps are designed to meet the highest standards in cleanliness and performance.