A client in the construction industry with a significant contract at a large oil refinery contacted us as they had encountered a problem with their system.

Work was halted very quickly during the operation due to flooding in the bays where the contractors worked daily. There was pressure for the system to be up and running again, with essential deadlines to hit and work not being resolved until the flooding was resolved. Tapflo UK quickly stepped in and supplied an emergency pump solution to deal with the flooding and therefore the client could return to normal operation with limited consequences of down time.

Application Details

Tapflo UK were contacted on an urgent request following a problem in which two of the bays where workers were stationed had flooded, and therefore the operation was halted until the flooding was resolved and in a workable condition.

Upon investigating the pump operation, it was quickly discovered that the bays were filling up fast with a mixture of thick oily silt and nearby seawater. Due to the location of the bays, the fluid and silt required pumping 50 meters to a waiting tanker. To further complicate matters, the pump would have to be suspended from a crane over the bays to effectively and quickly pump the flooded bays dry.

Tapflo jumped at the chance to help find a suitable oil refinery pump solution suited to all the application characteristics.

Oil Refinery Pump Solution

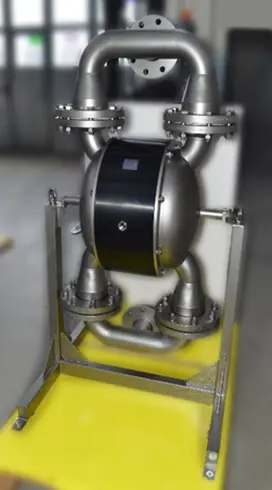

A powerful, robust and versatile 3” Diaphragm Pump (model TX820STT) was selected from our Sanitary Diaphragm Pump range after reviewing the options available. The pump is ATEX Rated, so it meets regulations on the chemical site and features AISI316L Construction with PTFE Internals. As the pump would have to be above the flooding on-site, this self-priming air-operated diaphragm pump (AOD) was the ideal solution.

The pump selected features flap values which allow it to pump large volumes of liquids containing large solids (up to 15mmø) or thick silt on this occasion. The pump can self-prime up to 9 meters and be hung from the crane due to having eye hooks. It also comes with the option of a Pneumixer to help keep the silt from settling at the bottom of the storage tank.

Features & Benefits

This Diaphragm model was selected as the oil refinery pump solution due to many factors, some of which include:

- Lubrication-free air distribution system

- Maintenance-free ball check valve system

- Total visual inspection of the wetted parts

- Supports CIP and SIP & can turn 360° to drain the pump

- Manifold clamps and the housing screws are simply removed for complete disassembly and cleaning

- Clean face, no-nut diaphragms to reduce the risk of leakage and make cleaning simple

The key to finding the right pump solution was by gaining a thorough understanding of the problem at hand, the pumping requirements, and site regulations and restrictions. This was achieved through an in-depth phone call with our client and understanding the severity and urgency of the issue they faced.

If you’re looking for an emergency pump solution, contact our team of pump experts. We’re here to discuss your needs and quickly find a pump solution to meet your requirements!