Application Details

Our client’s application is a wastewater by-product with hazardous red phosphorus contaminated water produced from cleaning large sheets. These sheets were created during the manufacturing of the warhead of a flare missile. The fluid is stored and filtered in 25L jerry cans with a duty to be emptied every few minutes, so the pump solution needed to be able to meet these requirements ensuring it was also suitable for an ATEX environment.

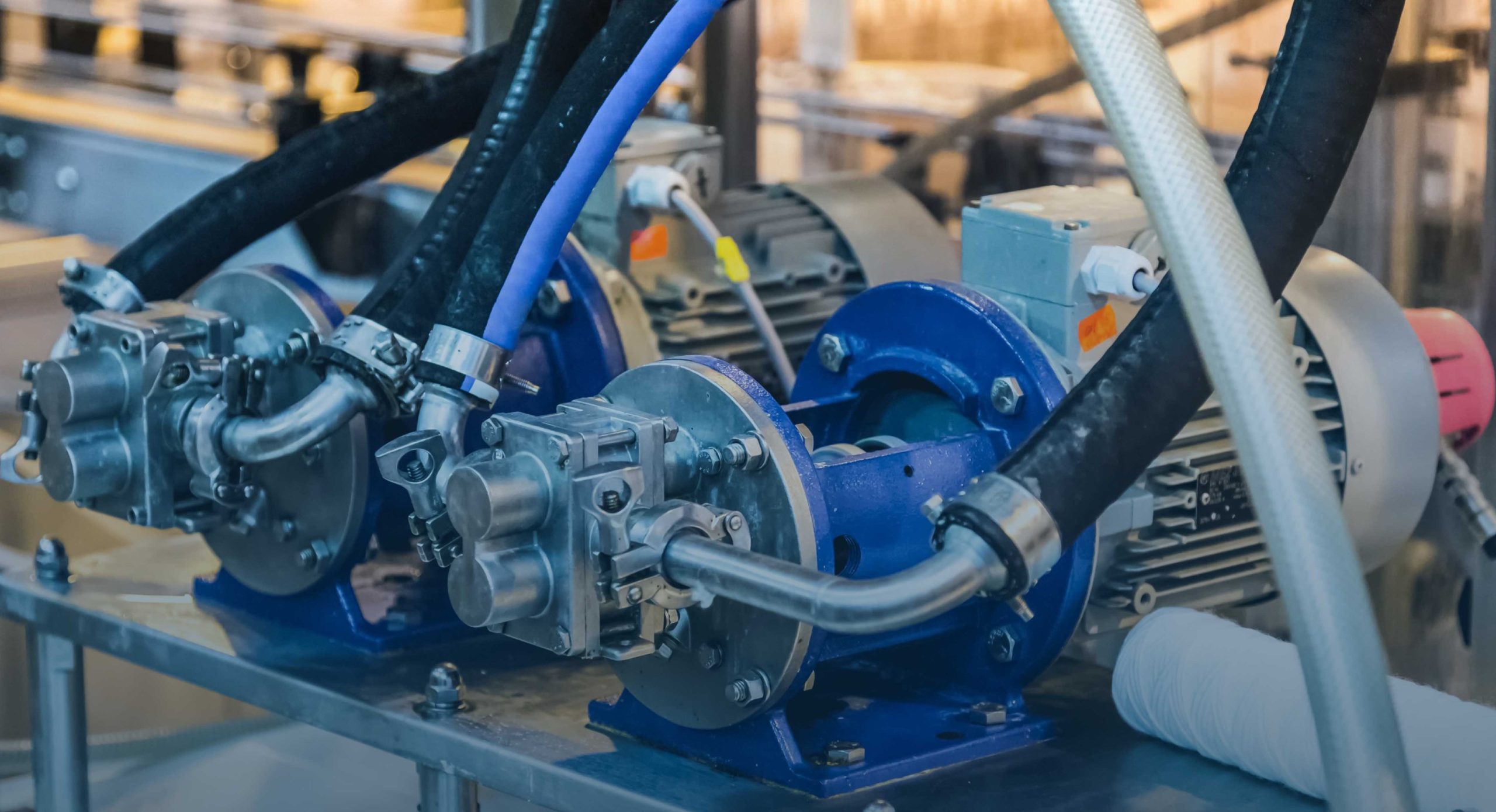

Pump Solution

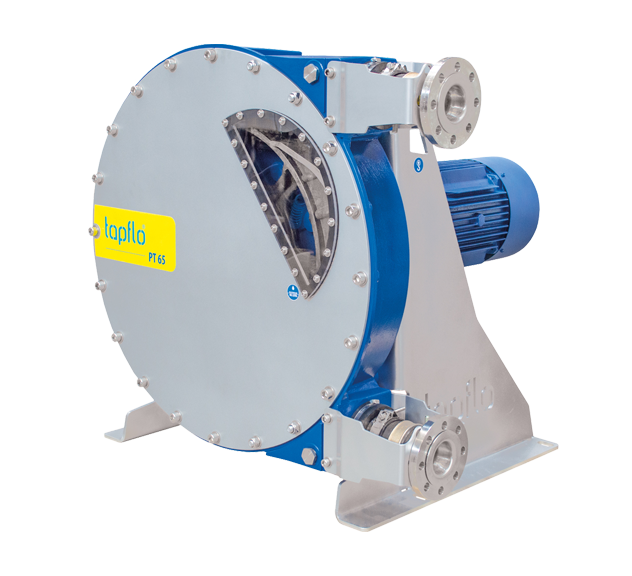

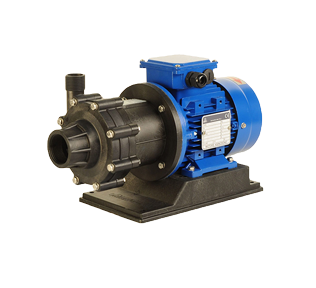

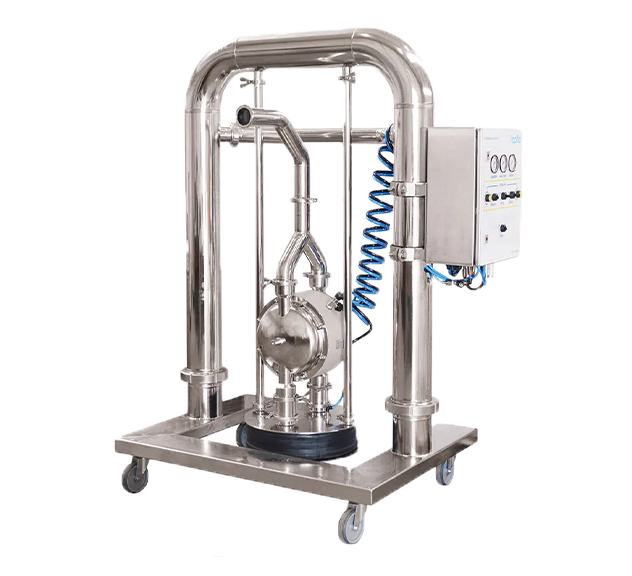

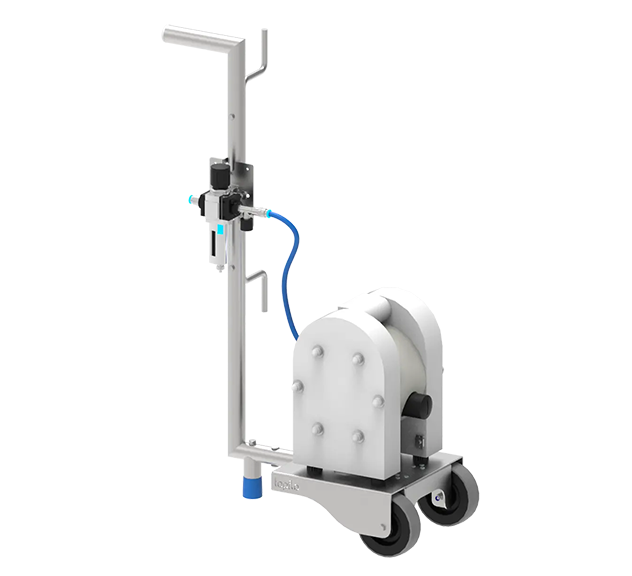

To meet the needs of the client pumping duties, we selected the MDU-20 system which is our mobile decanting unit that combines a Tapflo Air Operated Diaphragm Pump with a Tapflo UK Pneumatic Batcher, PoD Valve (Point of Dispense) and a purpose-designed trolley to accommodate the required 25L jerry can. However, due to the MDU-20 system not being ATEX certified as standard, we had to customise the pump to create a more bespoke system for the client that would effectively meet their needs. This included being fitted with filtration housing, Air hosing + pneumatic ancillaries and flexible hosing linking the MDU and filter together. The full ATEX certification ensures high safety measures have been taken into consideration prior to supply. This includes our ATEX Batcher unit.

One of Tapflo’s technical sales engineers took a site visit prior to the order being placed to check the requirements and installation. We also provided training for the onsite operatives to make sure they knew the operation of the pump system and emptying and filling requirements.

Features and Benefits

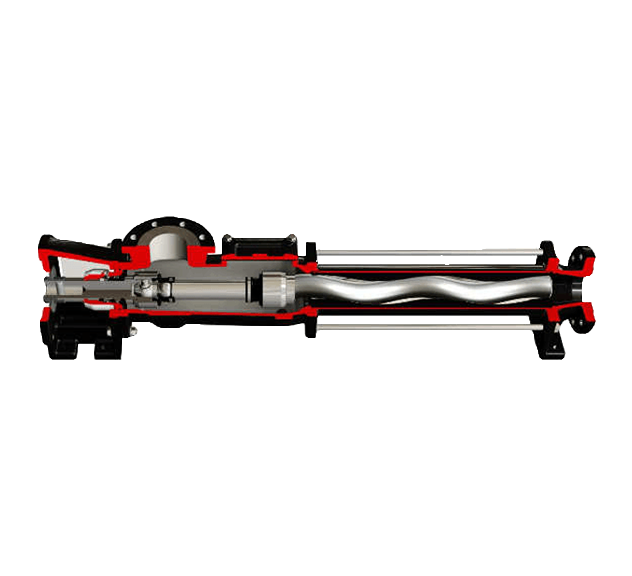

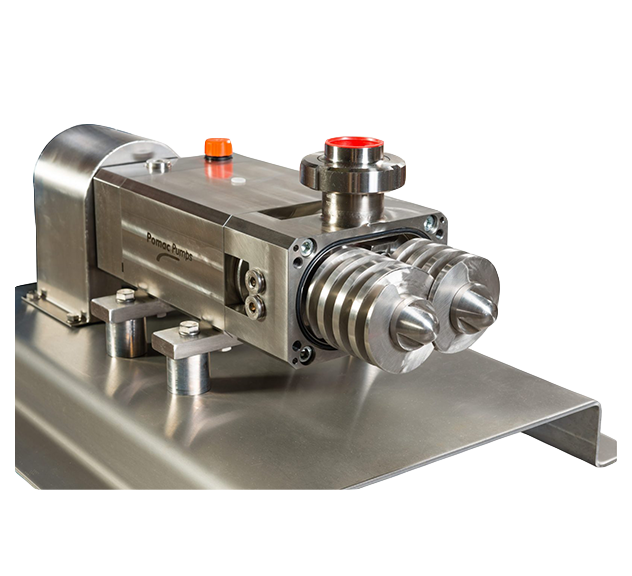

The MDU-20 system has a variety of features to make it an ideal solution for pumping and decanting duties. With its simple and ergonomic design, it allows for easy dispensing of 25ltr jerry cans with minimal idle time for operators. Plus, the design maximises the working life of the pump (TX50 PTT) as it does not run dry for long periods of time, nor can suction assembly become clogged. With its trolley construction, it has been built with manoeuvrability in mind to make it easy to move around the factory floor while still being compact to fit through standard doorways.

The MDU system also provides health and safety precautions to be maintained as the check valve on the suction line within jerry can prevent spillages of potentially hazardous fluids as the jerry can is emptied and removed from MDU. This also removes the risks associated with carrying open containers of chemicals to the process line through the factory.

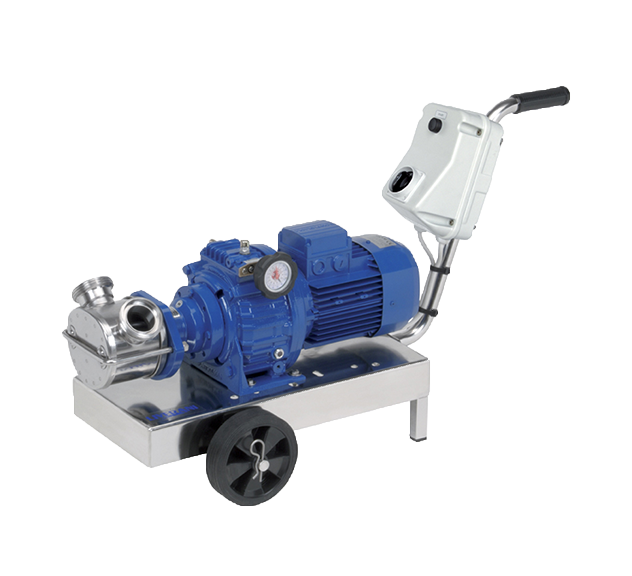

We are now supplying an additional mobile trolley system for this customer to be fitted to the existing pump system which features a new TX50 PTT on a trolley with suction & discharge hose to empty the inside IBC to the outside IBC to prevent needing a forklift to go inside the red waste room.

Due to the end user’s environment being ATEX, we were not able to get photos of the MDU-20 installed on site. Here are some images of an MDU-20 we have built for a client in the past.