A food manufacturer reached out to Tapflo UK in search of pumps that could pump viscous fluids containing solids from IBCs into large ribbon mixers. Tapflo UK were able to help and supply 2x LPX50 & 2 x LPX80 units with flow meters and batch control panels.

Application details

A first-time buyer, a food manufacturing company specialising in cakes, chilled desserts like cheesecakes, crumbles, pies, sponges and more, contacted Tapflo UK when they required a pump that could accurately pump batches of Apple Puree, and Cake Mixture (containing solids) from individual IBCs into separate large, ribbon mixers for production.

Fluid details

Apple Puree

- Viscosity: ~1500 cPs

- Density: 1000 kg/m³ (approx.)

- Temperature: Ambient – 20ºC

- Volume: 300kg batch 5-10 minutes

- Capacity: 4m³/hr (66.67 l/min) @ 3 Bar Differential Pressure

Cake Mixture (2500 cPs containing chopped raisins and fruit)

- Viscosity: ~2500 cPs (containing solids)

- Density: 1000 kg/m³ (approx.)

- Solids: <9mm

- Temperature: Ambient – 20ºC

- Volume: 100kg batch 5-10 minutes

- Capacity: 15m³/hr (250 l/min) @ 3 Bar Differential Pressure

The challenge

The food manufacturer required accurate dosing of ingredients into their production line; the pumps, hoses and accessories selected would have to be hygienic, with leak-proof seals, and capable of pumping viscous fluids effectively without blockages. A fitted monitor on the pump would be ideal as the client could determine the batch and see runtime and other operating statistics whilst in use.

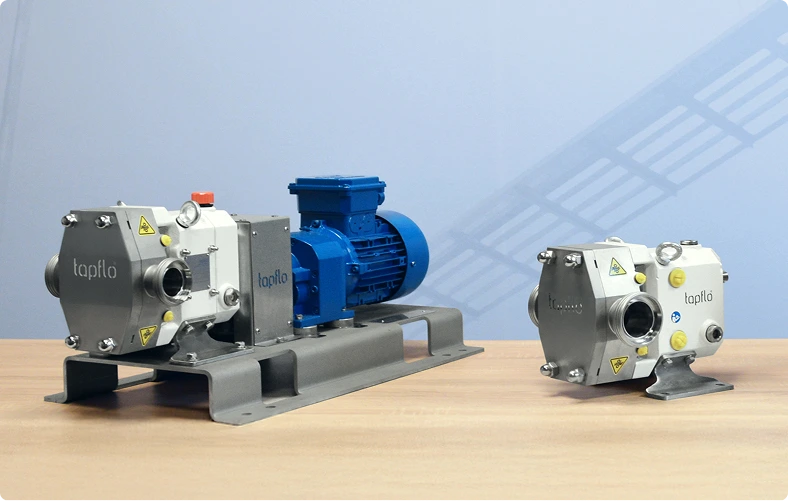

Components of the hygienic lobe pump system

Our team of expert engineers considered the requirements of the applications and supplied food-grade lobe pumps, as these are best suited for the material, flow rate, capacity and other factors.

The Food-Grade Hygienic Lobe Pumps were selected due to their hygienic components and their ability to transfer viscous and solid-containing materials. Flow meters and control panels were also supplied to ensure consistent batches and user control.

Apple Purée & Cake Mix Pump System:

4 x LPX50-1-2DC4Z-15/2700T-N – Horizontal, Long Coupled, Food Grade Lobe Pump

- Double mechanical seal

- Flushing pot and buffer fluid reservoirs – increase suction and dry-run capabilities whilst priming

- Hygienic motor shrouds

- Vibrating fork dry-run protection

- Discharge pressure sensor with display for dead-head monitoring/protection

Details and Specifications of hygienic lobe pumps

- Rotor Type: Tri-Lobe

- Displacement: 0.3 Litres/Rev

- Rated Capacity: 4 m³/hr (66.67 l/min) @ 3 Bar Differential Pressure

- Rated Speed: 234 rpm

- Absorbed Power: 0.64 kW

- Efficiency: 51.11%

- NPSHr: 1.1 m

- Max Differential Pressure: 10 Bar

- Suction / Discharge Connections: DN50 – Tri-Clamp, SMS3017

- Material of pump, lobes, shaft and baseplate: Stainless Steel AISI 316L

- Shaft Sealing: Double Mechanical Seal – SiC / SiC / FKM / AISI 316L + SiC / SiC / FKM / AISI 316L (FDA Approved)

- Coupling: Flexible w/ Guard (AISI 304L)

Flow Meters

- 2 x Micro Motion F-Series F200S Coriolis Hygienic Flow Meters

- Density & Viscosity Measurement.

- 2″ Tri-Clamp Connections,

- AISI 316L Housings.

- 15% mass flow accuracy & 0.002 g/cc density calibration accuracy.

Control Panels

- 2 x Bespoke, Variable Speed, IP66 Rated, Control Panel

- Stainless Steel AISI 304

- 7″ Touch Screen HMI

Key capabilities of the hygienic lobe pump system

There are many benefits to this hygienic lobe pump system, including:

- Operate within the desired volume (Kgs) of Apple Purée

- Display of the Running Total as well as the pre-determined batch total

- Pump to automatically stop in the event of Dry Running

- Continuation of Batch (In the event of Dry-Running)

- Dead-Head Protection – Pump to automatically stop in the event of an Over-Pressure Scenario

- Pump Start-Up when System Pressure Drops – Valve Opens)

- Data Logging – Logs of delivered quantities with time & date stamps for each pump as well as alarms (Dry-Run, Dead Head etc…)

- Retention of memory & settings in the event of power failure

- TOSIBOX included – Enables remote access to control panel through a cabled Ethernet connection for commissioning assistance, troubleshooting, software/ programming updates

Benefits of the hygienic lobe pump system

The capabilities of the hygienic lobe pump system delivers many benefits including:

- Operator Efficiency: Both manual and automatic batch controls, an easy-to-read display and alarms for any failures

- Faster Batching: Easy batching and transferring of product for 24/7 operation

- Full Traceability: Every batch logged by volume, date, time etc

- Improved Hygiene: Hygienic components and double mechanical seal

The results

The pumping systems provided outstanding efficiency when pumping the viscous and solid-laden fluids from IBCs into industrial mixers for manufacturing. With FDA-approved materials and components and many added features and accessories, the client could continue with operation, being able to both manually and automatically control the batches, ensuring an even and pulseless flow.

If you have a similar application and need help finding a pumping system, our expert sales and engineering team will be happy to help find a perfect solution for you.

Contact us today