When a UK-based bleach manufacturer began struggling with supply chain issues and production inefficiencies, they realised the need for a smarter, more scalable processing solution.

They required an automated bleach blending and SLES dilution system that would not only be cost-effective but also streamline their process and reduce downtime.

Application Details - The Client's Challenge

SLES (Sodium Lauryl Ether Sulphate) is a key surfactant commonly used in bleach manufacturing, but it needs to be heavily diluted before it’s ready for production.

SLES is usually supplied at a 70% concentration, but it needs to be diluted down to around 27% before it can be used. At 70%, SLES has a viscosity of around 10,000 – 15,000cPs, depending on factors such as thermal and storage conditions. For production purposes, it needs to be within 1,000 – 5,000cPs.

At the heart of the client’s problem was their reliance on purchasing pre-diluted SLES (Sodium Lauryl Ether Sulphate), which created production bottlenecks, inflated their costs, and further limited production flexibility. Due to supply chain issues, our client had no choice but to purchase SLES already diluted to 27%. This created a new set of operational and logistical challenges:

- Production was limited by their supplier’s availability of pre-diluted SLES (with fluctuating prices impacting profitability).

- Inability to scale up production in response to consumer demand.

- Manual batch blending using IBCs significantly slowed down manufacturing time.

- Storing numerous IBCs took up valuable plant space.

Our client decided to purchase SLES at 70% concentration and dilute it to 27% on-site, allowing it to be fed directly into their production line. However, they had limited space within their facility and required the SLES solution to be stored at a constant temperature of 30°C to maintain stability.

Our Engineered Solution

Our expert engineering team, set to solve their immediate dilution issues and found an opportunity to reshape their entire bleach manufacturing process by fabricating a fully automated, custom-engineered liquid blending system.

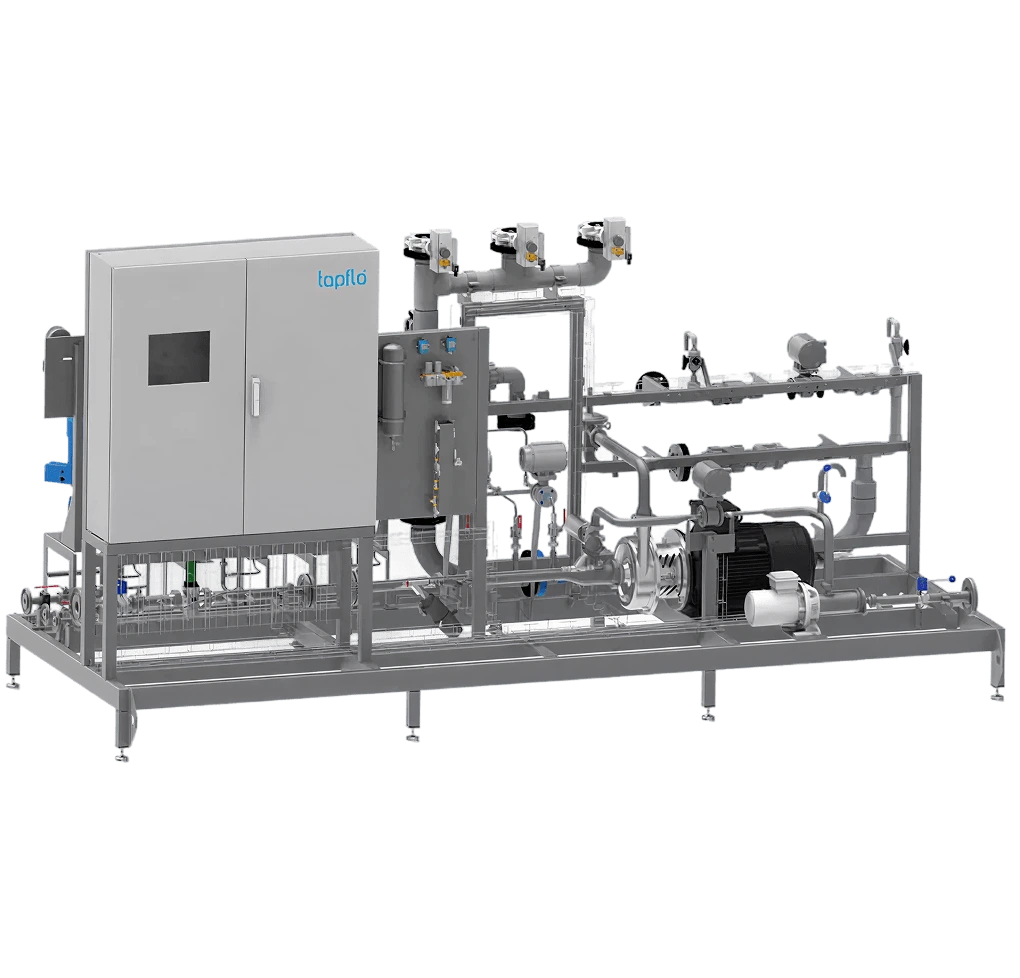

Following several site assessments and consultations, Tapflo UK proposed a complete upgrade: a custom-built, automated bleach blending system with integrated SLES dilution capabilities.

Key Features of this Solution:

- Built-in functionality to dilute 70% SLES down to 27%, either as a standalone process or as part of full bleach production.

- Accurate dosing of up to 7 ingredients for consistent, high-quality output.

- Custom system layout that is designed to fit within our client’s facility, owing to their space limitations.

- Heated and insulated bulk tank that is maintained at 30°C via trace heating and remote/local thermostatic control.

System Components & Capabilities

Our Liquid Blending System is a flexible and fully automated system designed to dose, mix, and dilute multi-ingredient liquids with high accuracy and repeatability. Paired with the custom bulk-storage tank, this system provided the client with all components necessary for a streamlined process.

Custom Bulk-Storage Tank:

- Manufactured from 6mm polypropylene with 50mm lagging.

- Integrated trace heating system.

- Thermostatic control offering both local and remote access.

Bespoke Bleach Blending System:

- Automated recipe-based control of up to 7 ingredients.

- Output capacity of 30,000L/hour.

- Visual monitoring of all ingredient tank levels.

- Automated switchover to holding tanks for continuous production.

- Designed with materials that are compatible with highly aggressive chemicals.

- Dual-mode functionality that allows for bleach blending or SLES dilution only, depending on production requirements for that cycle.

Impact & Results

The implementation of this custom-engineered system changed our client’s production process, delivering measurable improvements, such as:

- Faster production cycles with less manual intervention.

- Lower raw material costs and fewer supply chain dependencies.

- Elimination of IBC storage requirements.

- Automated dosing and blending for uniform product quality.

By delivering a scalable, fully automated system that’s tailored to our client’s unique constraints, our Engineering Team at Tapflo UK helped this bleach manufacturer take full control of their production process, solving immediate supply chain and operational challenges while positioning them for long-term efficiency and growth.

If you’re looking for a similar system for your facility, don’t hesitate to call or email our expert sales team today to assist with any needs you have.