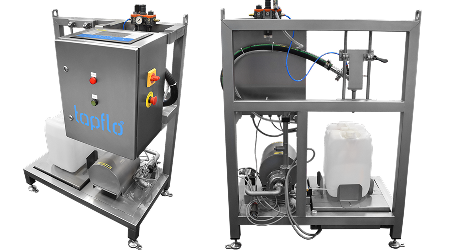

Filling Machines are designed for containers and tanks, delivering precise filling for a wide range of product viscosities and container sizes. Engineered for reliability and efficiency, it provides a cost-effective solution to simplify and enhance your filling operations.

Optimised for both accuracy and operational efficiency, the system maintains a high filling accuracy of over 99.9% and features an intuitive user interface with programmable pre-sets, batch filling options, and expanded functionality.

An accuracy of less than 0.1% to ensure consistent filling every time.

Available in a wide range of sizes to suit various containers and batches.

Manufactured in stainless steel AISI 316 for long-lasting durability.

Features a 7” display for quick manual operation and automated batch control.

Dry-run protection, overpressure protection and container presence detection.

TANKS/CONTAINERS:

Drums:

Standard metal or plastic drums for industrial and food-grade liquids.

Jerry Cans:

Rectangular containers containing smaller quantities, often containing chemicals or fuels.

Buckets:

Open-top and lidded containers used for food, beverage, chemical and industrial uses.

Bottles:

Glass and plastic, suitable for beverages, pharmaceuticals and cosmetics.

Steel tanks:

Corrosion-resistant vessels used in sanitary and industrial processes.

Bags:

Soft and collapsible, used mainly for food and beverages.

PUMPS:

Compatible with many Tapflo Pumps

Diaphragm, Centrifugal, Lobe, Peristaltic, Twin Screw and many more.

AN EFFICIENT PERFORMANCE YOU CAN RELY ON

Precision of the system:

Over 99% filling accuracy.

Filled liquid viscosity:

Up to 1,000,000 cPs.

Size of the filled containers:

From 1 to 1000 litres, depending on the configuration of the system.

Ready to build a system tailored to your needs? Speak to our team today.