EUROPE

ASIA & PACIFIC

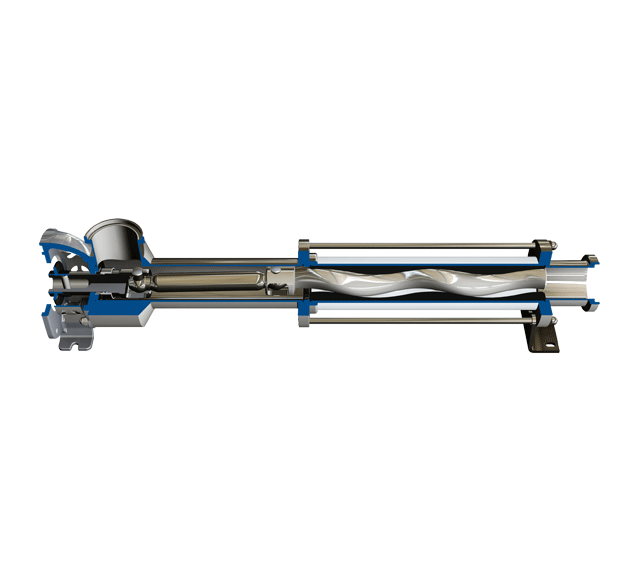

Our Hygienic Progressive Cavity Pump is the ultimate sanitary solution designed for industries requiring superior cleanliness while ensuring product integrity is not compromised. Forming part of the Diamond Series, the Hygienic range comprises the JX, JXC, JXO, DX, DXC and DXO models. Featuring stainless steel construction, a design that facilitates drainage and eliminates dead zones as well as CIP & SIP functionality, these 3A and EHEDG-certified pumps ensure optimal cleanliness and compliance with the strictest sanitary standards. Furthermore, these pumps offer self-priming capabilities up to 7m, and are ATEX-available for use in hazardous environments.

Typical applications for our Hygienic Progressive Cavity Pump:

Max. Flow:

Max. Head:

Max. Temp:

Material:

110m³/hr

480m

150°C

Metal

The DX Hygienic Pump series is an ideal solution for use within the Food, Pharmaceutical, Chemical and Cosmetic industries. The complete sanitary design, in compliance with standards EHEDG and 3A, ensures maximum sanitisation.

These pumps are highly rated for their CIP (Clean In Place) and SIP (Sterilising In Place) functions. The layout of the pump is designed specifically to allow for drainage and to avoid dead zones. All parts that come into contact with the product are manufactured from stainless steel (standard in AISI 304). The block and base plate can be manufactured from this material upon request.

The complete range of pumps can be manufactured with block construction (DXO series and DXC series) or bearing housing with independent shaft (JXO series and JXC series).

Their sanitary design complies with EHEDG & 3A Standards and is suitable for both CIP & SIP Cleaning & Sterilising procedures. Their special geometry allows for complete draining and avoiding dead zones where bacterial build-up and contamination can occur on standard Industrial designs. On request, all non-product contact parts can be supplied in Stainless Steel AISI 304 to increase their suitability for use in sanitary zones. Similar to the Flanged Industrial Series, the Hygienic Series can be delivered in either a Close Coupled Orientation (DX) or Flexibly Coupled Orientation with Bearing Bracket Support (JX). Either variant can be supplied with either an Open Pin Joint design (DXO / JXO) where the joint lubrication is facilitated by the pumped fluid (non-abrasive & lubricating) or Closed Pint Joint design (DXC / JXC) where the joint is sealed and lubricated independently from the pumped fluid making it suitable for sticky, non-lubricating or abrasive fluids.

| Max Flow (m³/hr) | 110m³/hr |

| Max Pressure (m) | 240m (480m on K8) |

| Temperature Range (°C) | -40°C up to +150°C |

| Connection Options | DIN 11851, Clamp ISO 2852, Clamp ASME-3A, Clamp DIN 32676, RJT, SMS 1145, Garolla, Macon |

Largest UK Stock

Same Day Quote

Fastest Delivery

Largest UK Stock

Same Day Quote

Fastest Delivery

Our friendly team at Tapflo UK would be more than happy to assist you further with any pump solutions, delivery information or questions you have. If you need additional support on-site, you can speak to a member of the team today to organise a site visit.

Give us a call now:

Search our pump support articles: